Heat-generating applicator head

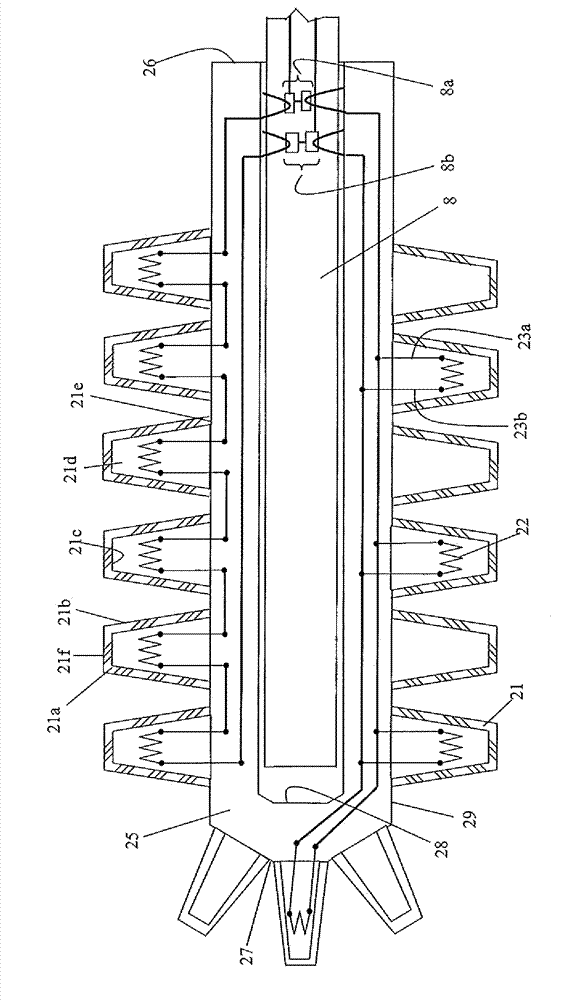

By arranging independent heating elements inside or on the outer surface of the eyelash modification element, the problems of heat loss and uneven heating in existing heated mascara applicators are solved, and a more efficient mascara heating effect is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

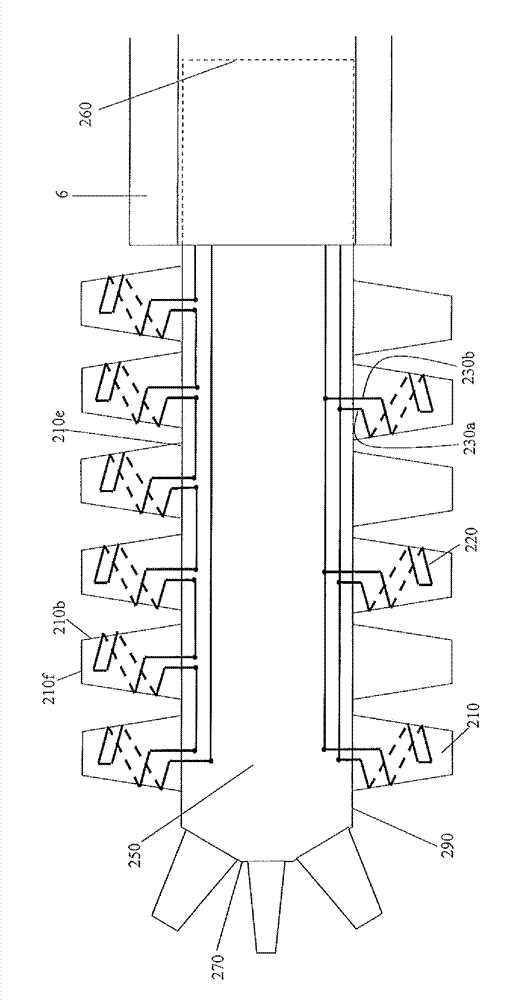

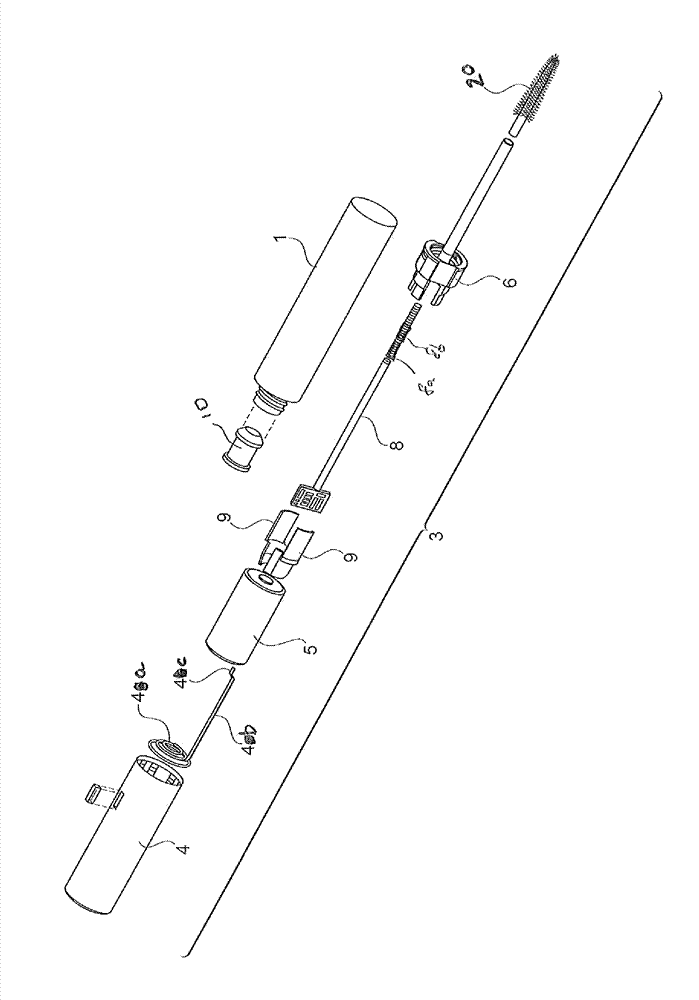

[0018] This application relates to applicator heads for heated applicators or other hand-held grooming implements such as brushes, combs, and the like. The main focus of this invention is the mascara applicator. Although the principles presented herein can be applied more generally, the principles will be presented with reference to a mascara applicator and mascara application.

[0019] definition

[0020] "Applicator head" means the part of an applicator that delivers product from a product container to an application surface, such as skin or hair. The applicator head may be provided with grooming elements that help deliver product to a specific application surface (ie, eyelashes) and spread the product thereon.

[0021] For example, "lash grooming element" refers to the portion of the applicator head that engages eyelashes by applying product, spreading product, and / or grooming the eyelashes (eg, by rearranging the eyelashes). Bristles are a common type of lash grooming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com