Device with association tosupporting multi-paper-path digital printing and digitalized traditional rotary press

A technology of digital printing and paper path, which is applied in the field of digital traditional rotary printing machines, and can solve the problems of inability to realize digital printing, large volume, and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

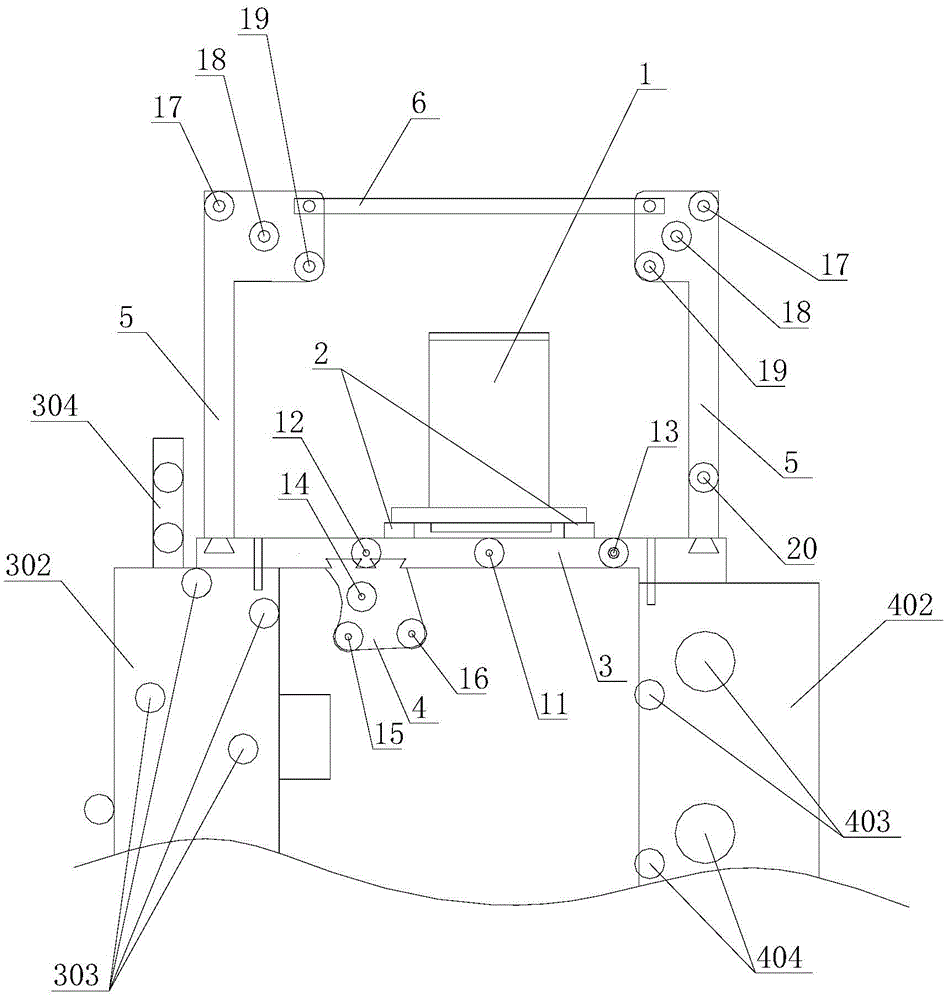

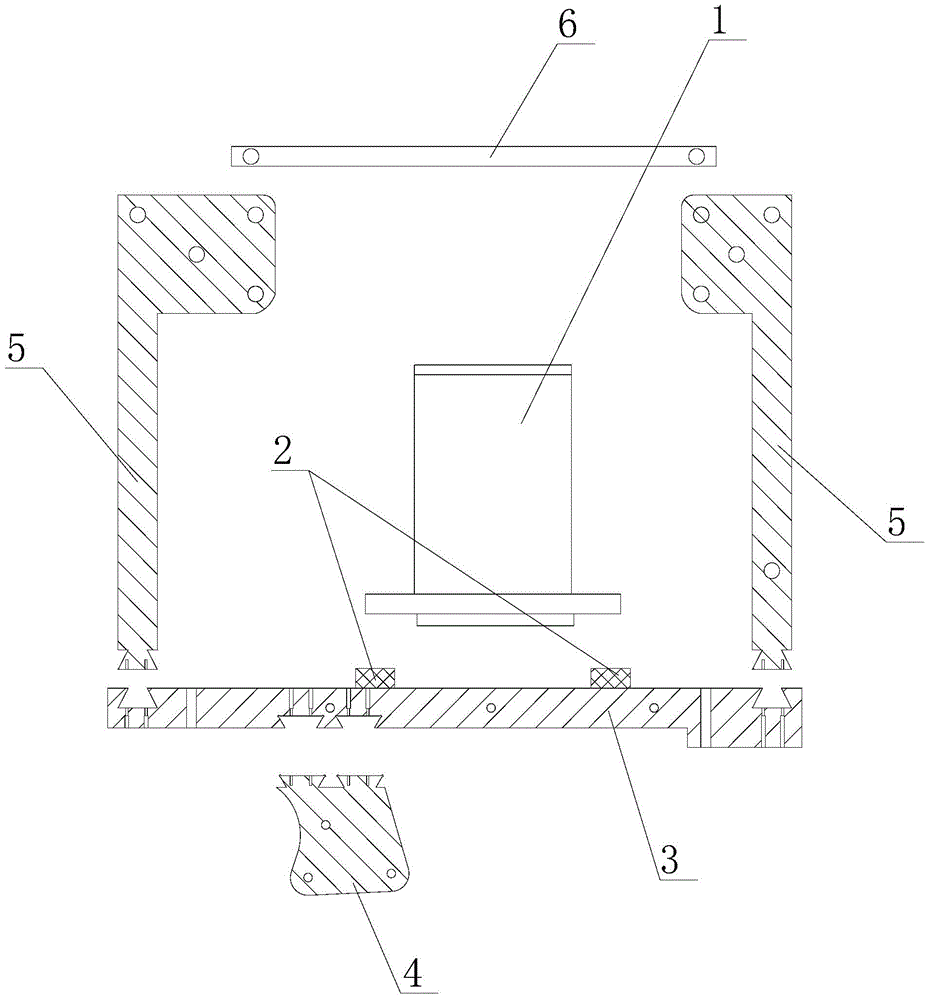

[0033] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

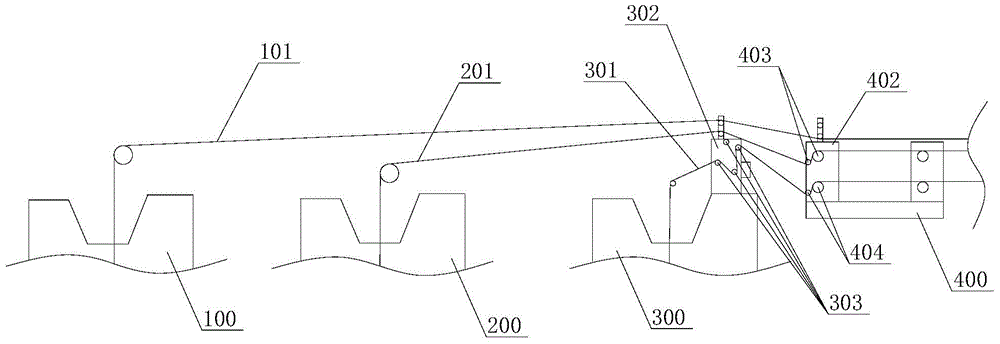

[0034] see figure 2 , 3 , the present invention provides a device supporting digital printing of multiple paper paths, which is directly installed on a traditional rotary printing machine, so that it can be directly upgraded to an improved device supporting digital printing. It includes a digital printing head 1 , a main frame, a printing paper guide roller 11 , a reversing paper guide roller group, a paper passing roller group and a paper output roller 20 . Wherein, the main frame is a foundation of the whole device, including guide rails 2 , two main beams 3 , two support plates 4 and four columns 5 . The above-mentioned two main beams 3 are parallel to each other, and preferably, the two ends of the two main beams 3 are connected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com