Universal self-adaption fixture for sliding friction-wear test

A friction and wear test and wear test technology, which is used in measuring devices, instruments, scientific instruments, etc., can solve problems such as affecting test results, uncertain additional wear in friction and wear tests, etc., and achieves low cost, simple structure and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form.

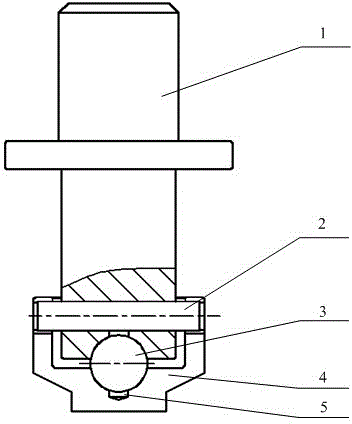

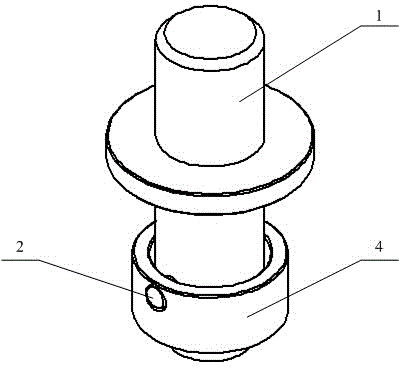

[0013] figure 1 As shown, a universal self-adaptive fixture suitable for sliding friction and wear test, including: force transmission shaft 1, positioning pin 2, steel ball 3, upper sample 4 and oil storage hole 5. The upper end of the power transmission shaft 1 is fixedly connected with the friction and wear testing machine, which is used to transmit the load applied by the friction and wear testing machine to the upper sample 4 through the steel ball 3, and transmit the friction force in the sliding friction to the force transmission shaft installed on it. 1 above the force sensor. The positioning pin 2 has an interference fit with the power transmission shaft 1 and a clearance fit with the upper sample 4. On the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com