Summer heat-relieving and thirst-quenching beverage and preparation method thereof

A technology for beverages and raw materials, which is applied in the field of summer-relieving and thirst-quenching beverages and the preparation thereof, can solve the problems of strong fishy smell of mung bean, inconvenience, destruction of mung bean organic acid and vitamins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Using the following mass percentages of raw materials, the beverage is prepared as follows: mung bean 0.2%, malt oligosaccharide with a molecular weight of 600, 0.1%, soy oligopeptide with a molecular weight of 1000, 0.8%, sucrose 6.0%, citric acid 0.006%, caramel 0.004%, sodium chloride 0.015%, potassium chloride 0.012%, purified water 92.863%.

[0069] The specific steps are:

[0070] A. Screening of main ingredients: Choose mung beans with full particles, no insect eyes, and no mildew, and wash them for use after weighing;

[0071] B. Gelatinized enzymatic hydrolysis: pump hot water at 90℃ of 15 times the weight of mung bean into the enzymatic hydrolysis tank. Turn on the stirring and put in mung beans. After gelatinization at 88°C for 60 minutes, add 0.08‰ heat-resistant α-amylase solution with an enzyme activity of 120KNU / g, and enzymatically hydrolyze at 88°C for 40 minutes.

[0072] C. Enzyme inactivation cooling: Use a heat exchanger to heat the mung bean juice after e...

Embodiment 2

[0079] The following mass percentages of raw materials were used to prepare the beverage according to the method described in Example 1: mung bean 1.4%, malto-oligosaccharide with a molecular weight of 600 1.9%, soy oligopeptide with a molecular weight of 1000 0.2%, sucrose 4.2%, citric acid 0.02 %, caramel 0.01%, sodium chloride 0.02%, potassium chloride 0.015%, purified water 92.235%.

Embodiment 3

[0081] The following mass percentages of raw materials were used to prepare beverages according to the method described in Example 1: mung bean 4.0%, malto-oligosaccharides with a molecular weight of 600, 5.0%, soy oligopeptides with a molecular weight of 1000, 0.02%, sucrose 0.3%, and citric acid 0.001 %, caramel 0.0004%, sodium chloride 0.001%, potassium chloride 0.001%, purified water 90.6676%.

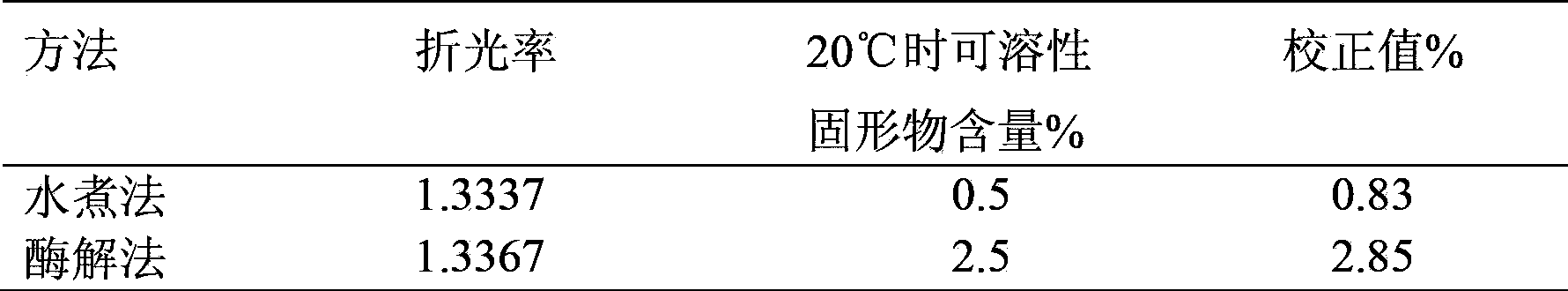

[0082] The main nutrients in mung beans are carbohydrates, which are also the main energy substances. But these carbohydrates are mostly water-insoluble macromolecular starches. The traditional method of boiling mung bean soup with water is difficult to decompose starch, and most of the starch is discarded in the form of residue. Under the action of enzymes, starch will be hydrolyzed into smaller molecules of various water-soluble sugars, such as glucose, maltose, maltotriose, maltodextrin and a variety of oligosaccharides, thereby greatly increasing the carbohydrates in mung beans ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com