Preparation method of composite material bar for concrete structure

A technology for concrete structures and composite materials, which is applied in the field of manufacturing composite material bars for concrete structures in the construction industry, can solve problems such as poor thermal expansion coefficient adaptability, etc., and achieve the effect of strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

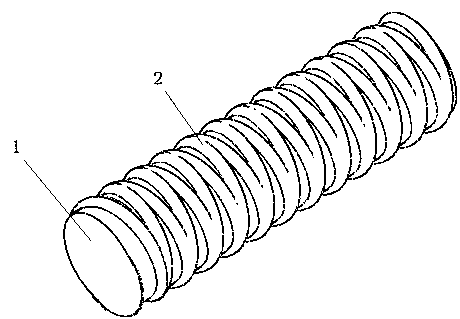

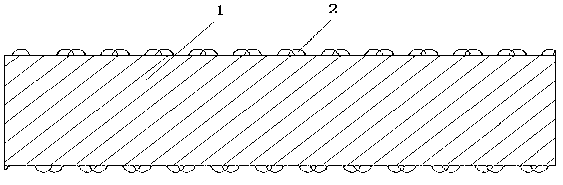

[0014] The total length of composite bars for a certain size of concrete is 1600mm, 30mm in diameter. Among them, the diameter of the glass fiber core is 26mm, and the height of the carbon fiber thread is 2mm. Pitch 8mm, Two strands of yarn are intertwined, such as image 3 . The preparation process is as follows: First, the resin-impregnated unidirectional glass fiber bundles are shaped by a mold with a diameter of 26 mm under tension; then, Before curing The surface is spirally wound with carbon fiber double-bundle yarns, the two bundles of yarns are crossed, the thickness of the yarn sheet is controlled to 2mm, and the winding parameters are adjusted to make the carbon fiber bundles press Pitch 8mm Winding to form threaded protrusions 2; finally, after curing together, cut to length 1600mm ie Get composite tendons.

Embodiment 2

[0016] The total length of composite bars for a certain size of concrete is 2000mm , 20mm in diameter. Among them, the diameter of the glass fiber core is 16mm, the height of the carbon fiber composite thread is 2mm, the pitch is 5mm, and the single thread is wound, such as Figure 4 . The preparation process is as follows: First, the resin-impregnated unidirectional glass fiber bundles are drawn by a pulling force after being shaped by a mold with a diameter of 16mm; then, Before curing The surface is spirally wound with a single bundle of carbon fiber yarn, the thickness of the yarn sheet is controlled to 2mm, and the winding parameters are adjusted so that the carbon fiber bundle is wound with a pitch of 5mm to form a thread protrusion 2; finally, after curing together, intercept 2000mm The length is the composite material rib.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com