Honeycomb core material

A honeycomb core material, honeycomb technology, applied in resistance welding equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of large fluctuation of crush curve, unstable structure design and manufacturing, etc., to achieve maximum specific strength and high stability , the effect of reducing fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

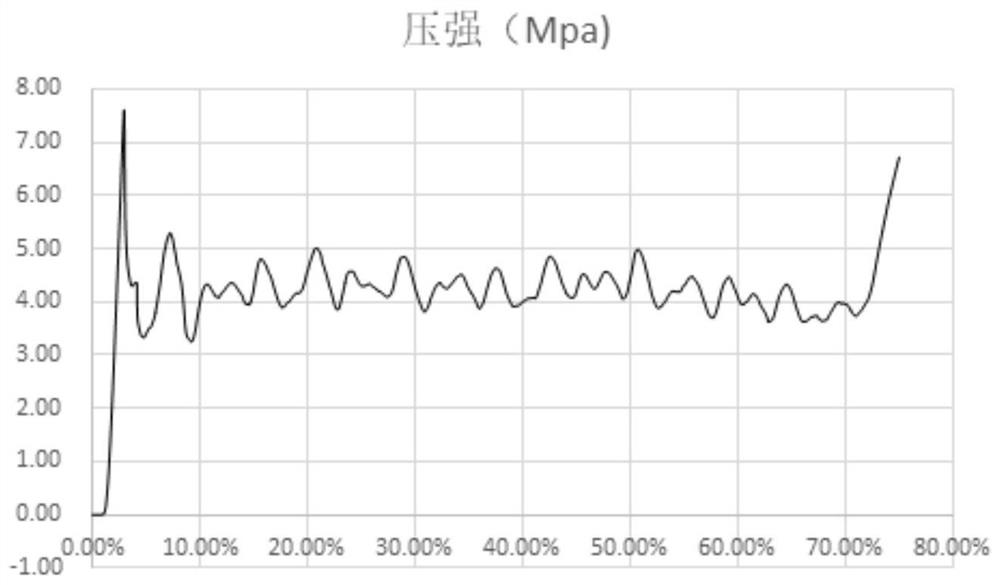

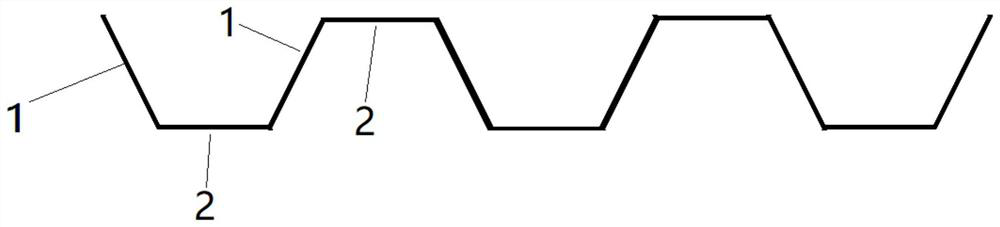

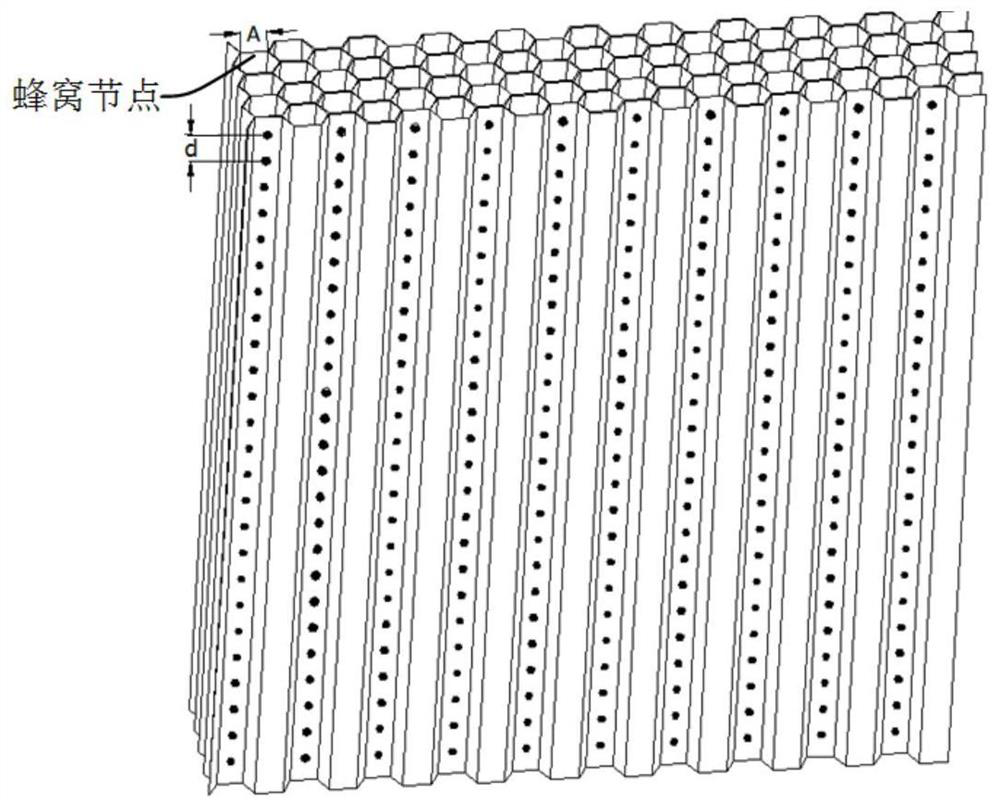

[0056] The size of the crush test honeycomb core: 100mm (length) × 100mm (width) × 100mm (height), the material is 304 stainless steel, the thickness is 0.13mm × the cell D6.4mm, the side length A of the node of the honeycomb unit is 3.70mm, The distance d between adjacent solder joints is set to 2 mm, and the honeycomb bands provided with concave and convex strips are stacked layer by layer to form a hexagonal honeycomb core.

[0057] In the honeycomb formed by the method of the present invention, the distance between adjacent solder joints d≤the side length A at the node of the honeycomb unit ensures that there is at least a solder joint support within the amount of progressive telescopic deformation of the honeycomb core lattice, so that the interior of the honeycomb core is within the minimum unit There will be no cracking and twisting on the surface, the overall welding strength is relatively high, and the solder joints are evenly distributed, so the crush curve of the hon...

Embodiment 2

[0059] The size of the crush test honeycomb core: 100mm (length) × 100mm (width) × 100mm (height), the material is 304 stainless steel, the thickness is 0.13mm × the cell D5.6mm, the side length A of the node of the honeycomb unit is 3.23mm, The distance d between adjacent solder joints is set to 2mm.

[0060] The electronic universal testing machine DNS-300 is used for compression test, and the test compression speed is 5mm / s. Through repeated tests, it is proved that the manufacturing method of the present invention is stable and feasible. The crush strength curve is stable, see Figure 10 Tested compressive strength curve.

Embodiment 3

[0062] The electronic universal testing machine DNS-300 was used to carry out the compression test, the test compression speed was 5mm / s, and the following test data were obtained through the test: Table 1, the compression strength curve is shown in Figure 11 and Figure 12 shown.

[0063] Table 1, crush strength test data at different stainless steel honeycomb heights

[0064]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com