Pneumatic tire

A technology of pneumatic tires and tires, which is applied in the direction of off-road vehicle tires, tire parts, tire treads/tread patterns, etc., which can solve problems such as insufficient effects, and achieve improved soil removal performance, improved mud performance, and improved adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

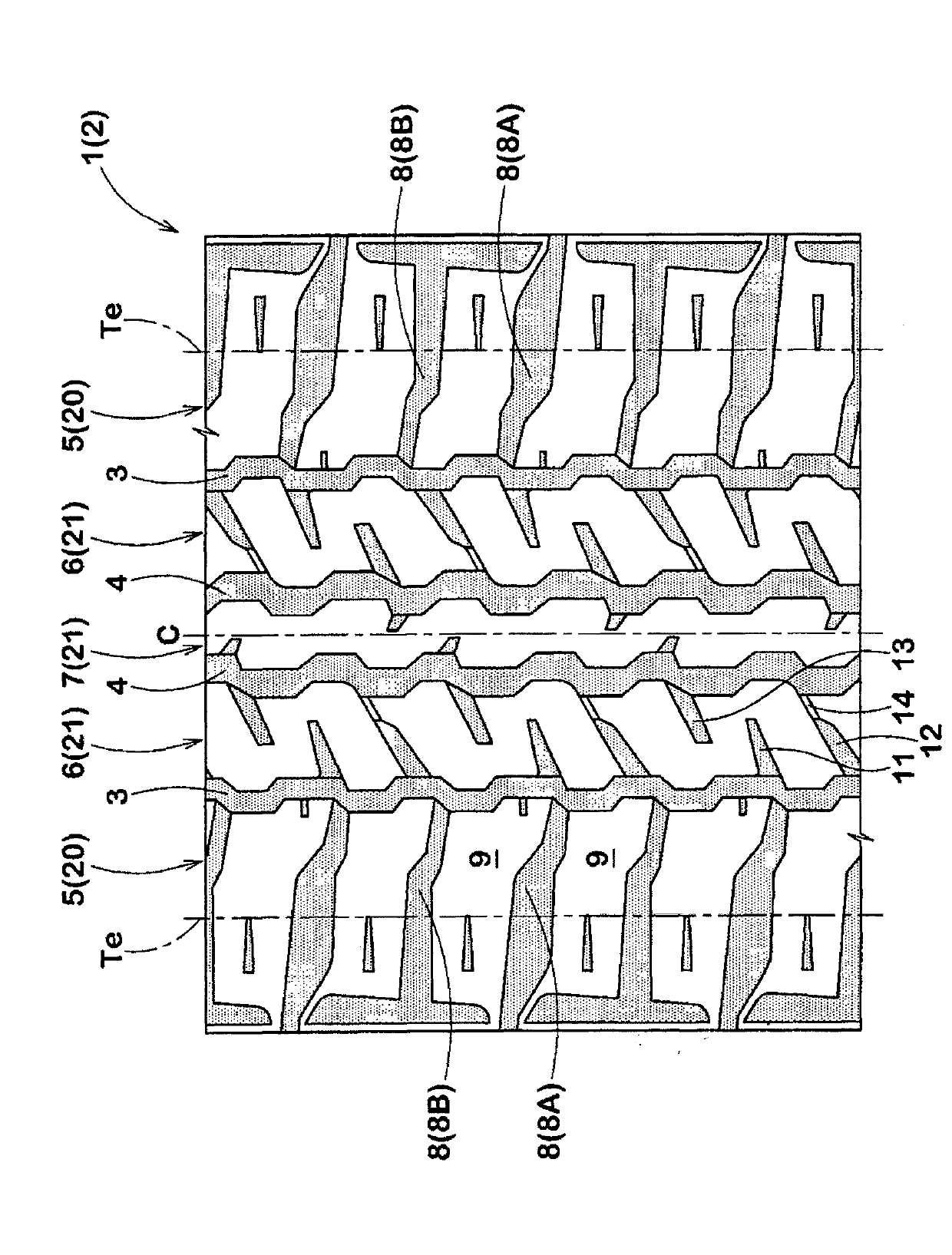

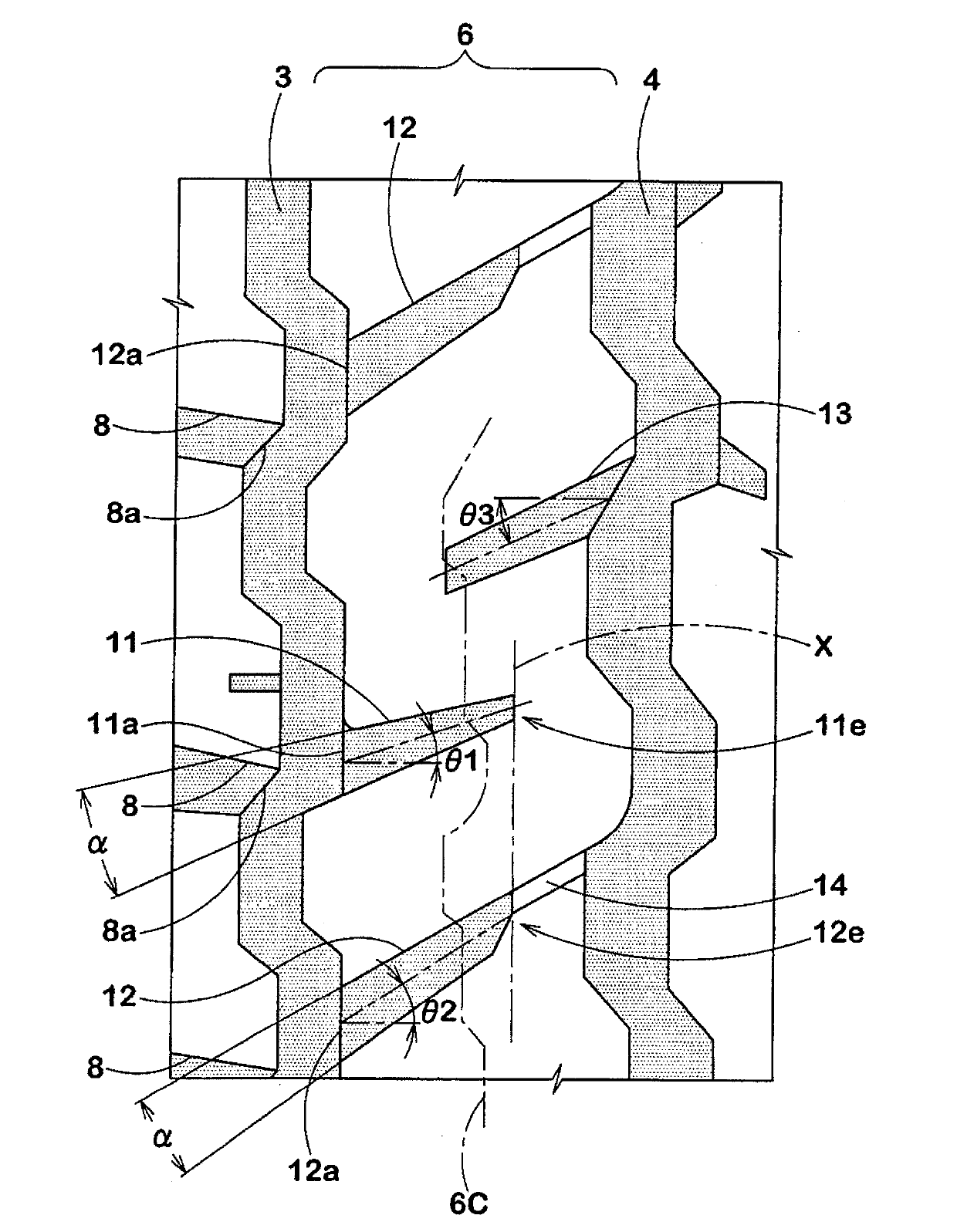

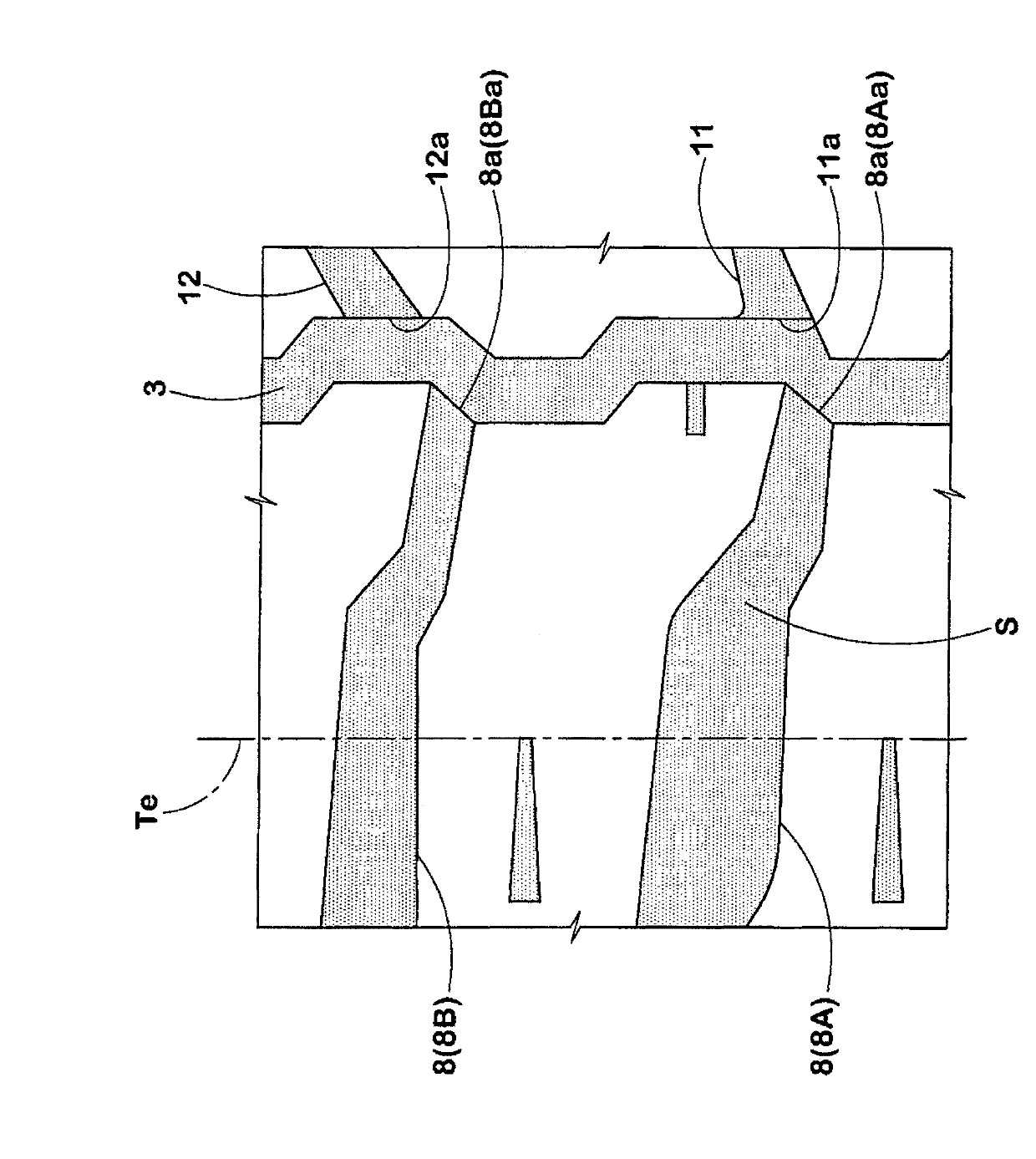

[0036] Hereinafter, embodiments of the present invention will be described in detail.

[0037] exist figure 1In the pneumatic tire 1 of this embodiment, the tread portion 2 is provided with a pair of shoulder main grooves 3 extending in the tire circumferential direction on the side closest to the tread edge Te, and a pair of shoulder main grooves between the pair of shoulder main grooves. 3. One or two crown main grooves 4 extending along the tire circumference. As a result, the shoulder land portion 5 is formed on the outside of the shoulder main groove 3 in the tire axial direction, and the middle land portion 6 is formed between the shoulder main groove 3 and the crown main groove 4 . In this example, a case where two crown main grooves 4 are provided is exemplified, and a crown land portion 7 is formed between the crown main grooves 4 , 4 .

[0038] The shoulder land portion 5 is provided with shoulder lateral grooves 8 at intervals in the tire circumferential directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com