Laminating machine and laminating method

A laminating machine and laminating technology, applied to chemical instruments and methods, measuring devices, instruments, etc., can solve problems such as lowering the yield rate of glass laminating, unobjectiveness, and inconsistent judgment standards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Referring to the following examples, the implementation of the laminating machine and the laminating method of the present invention will be described. Among them, laminating machines can be roughly divided into small-sized laminating machines and large-sized laminating machines. The so-called small-sized laminating machines are suitable for laminating substrates below 5 inches, and large-sized laminating machines Suitable for lamination of substrates such as 5 to 15 inches. In addition, the substrate may, for example, be made of glass, plastic, acrylic and other materials, which are not limited here.

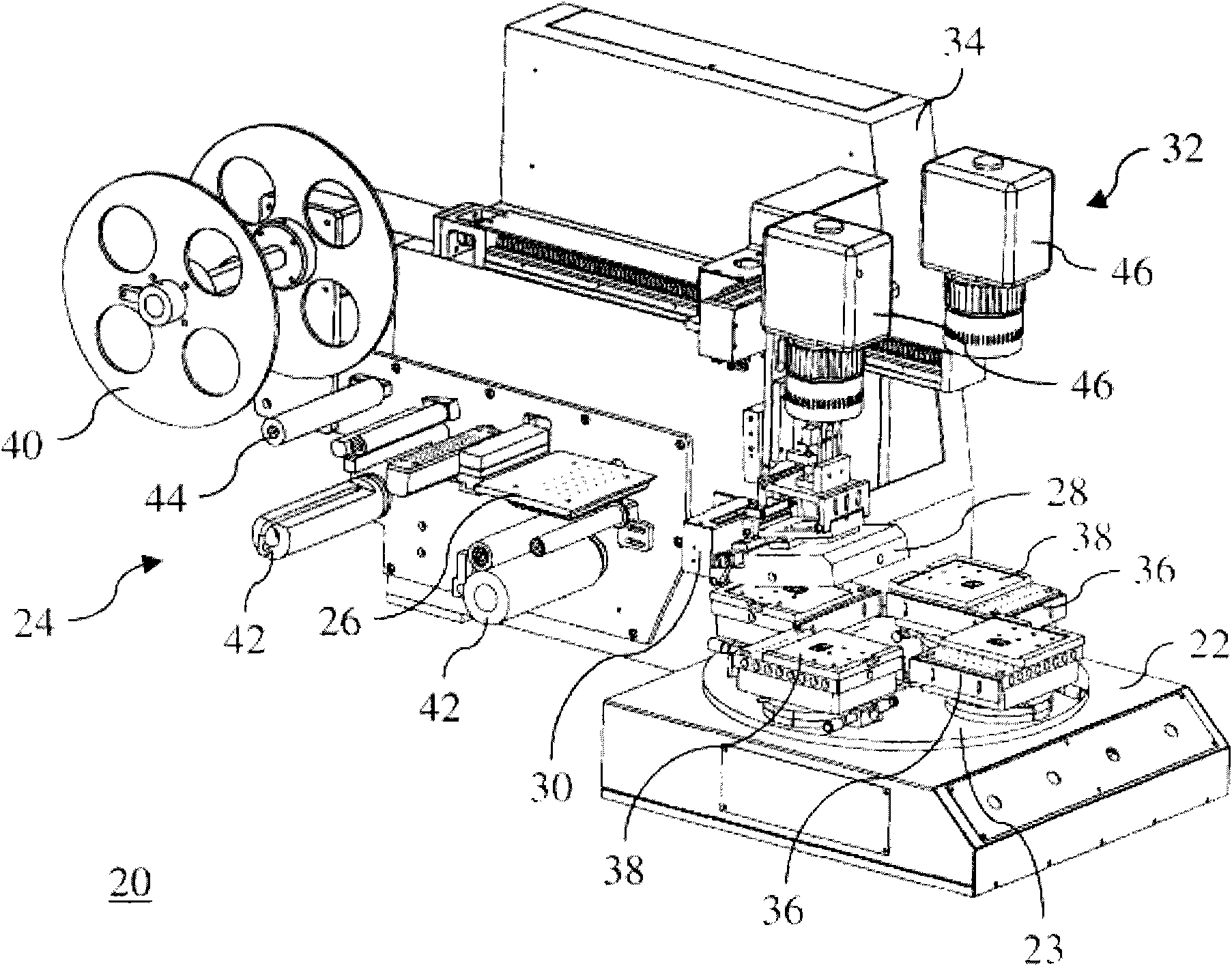

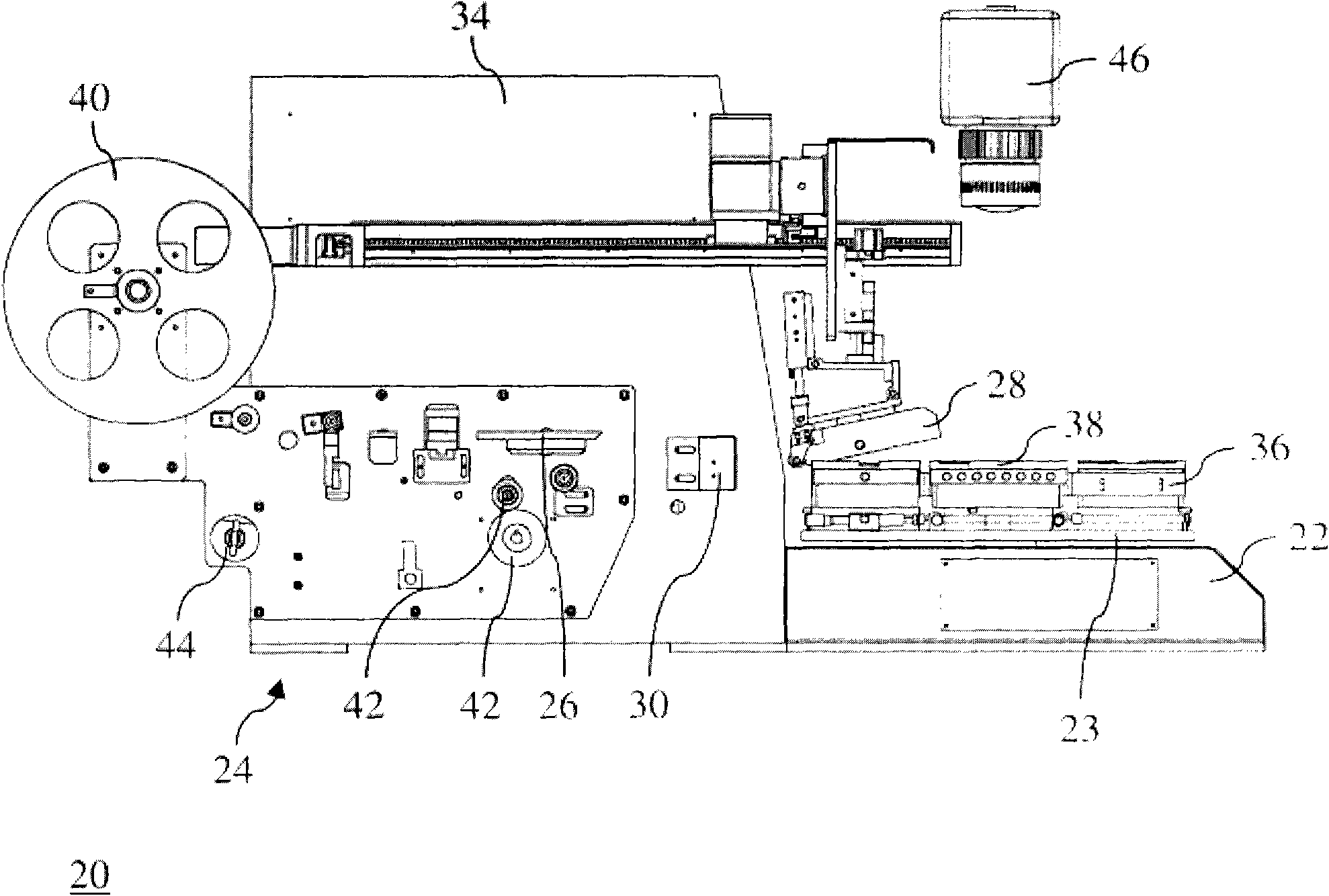

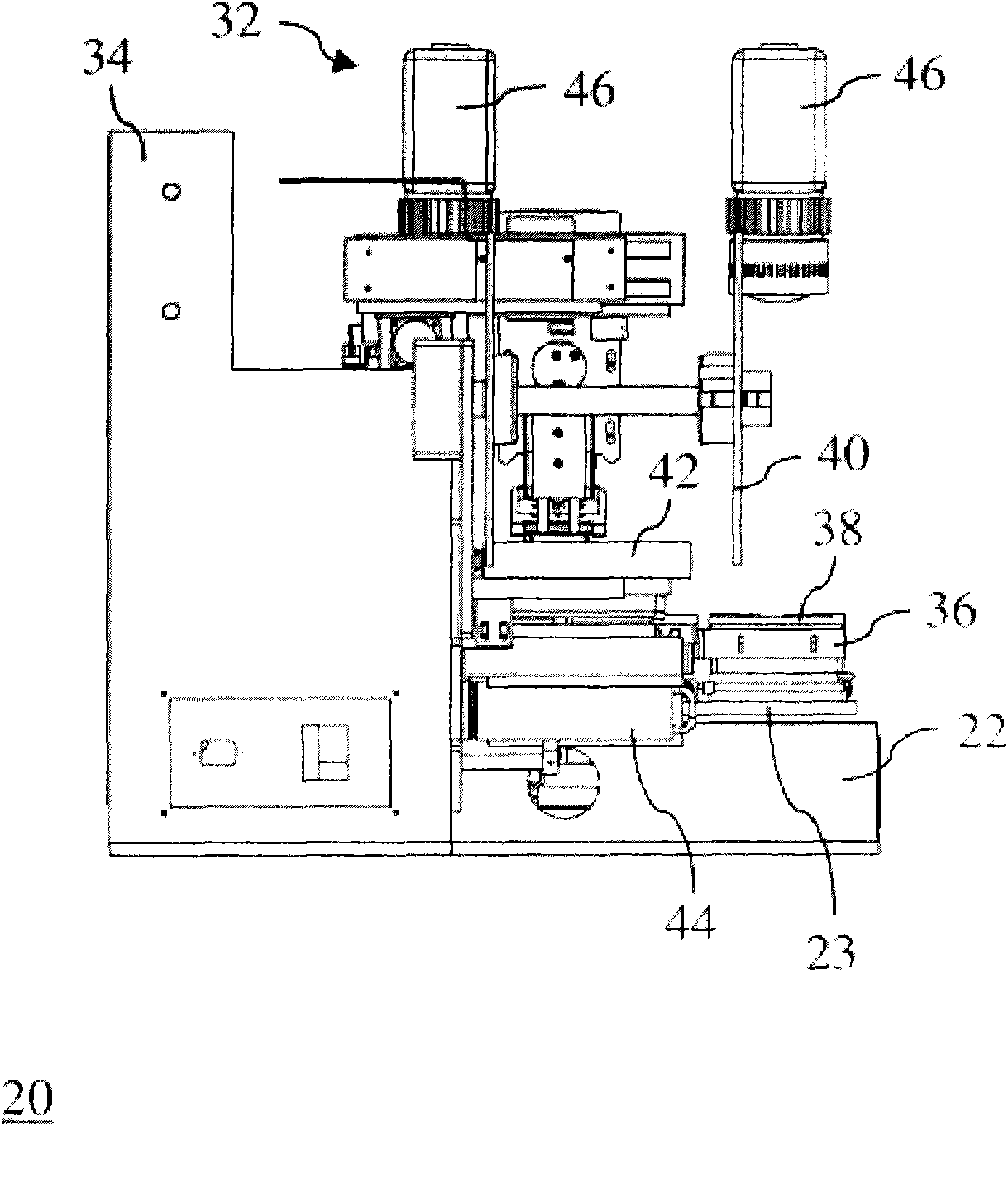

[0065] Please refer to Figure 1 to Figure 4 , are respectively the perspective view, side view, rear view and top view of the first embodiment of the laminating machine of the present invention. Among them, the first embodiment is, for example, used to illustrate the actual implementation of a small-sized laminating machine.

[0066] exist Figure 1 to Figure 4 Amon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com