Electronic-balance-based automatic silicon wafer counter

A technology of electronic balance and computing device, which is applied in the field of silicon chip automatic counting device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

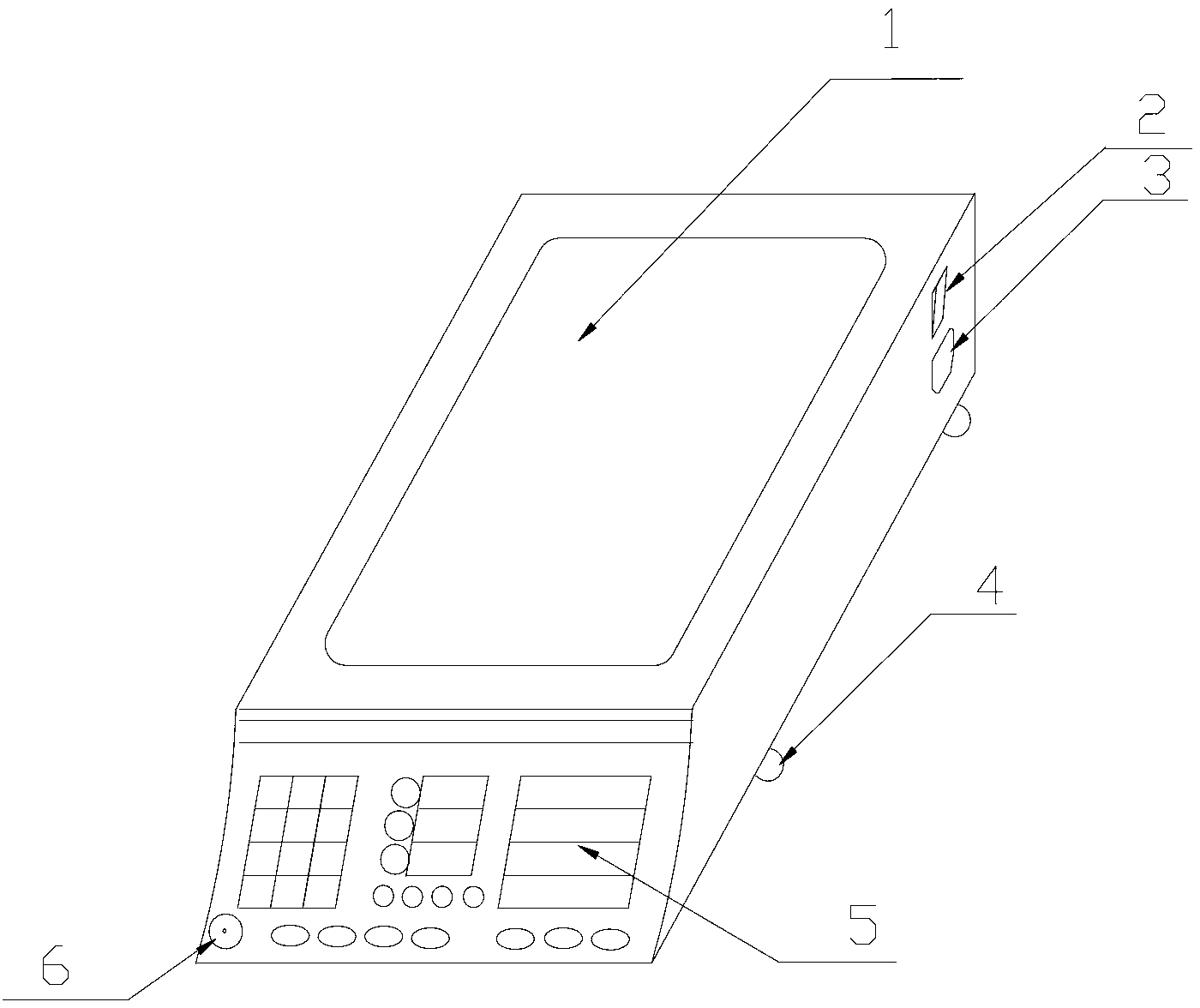

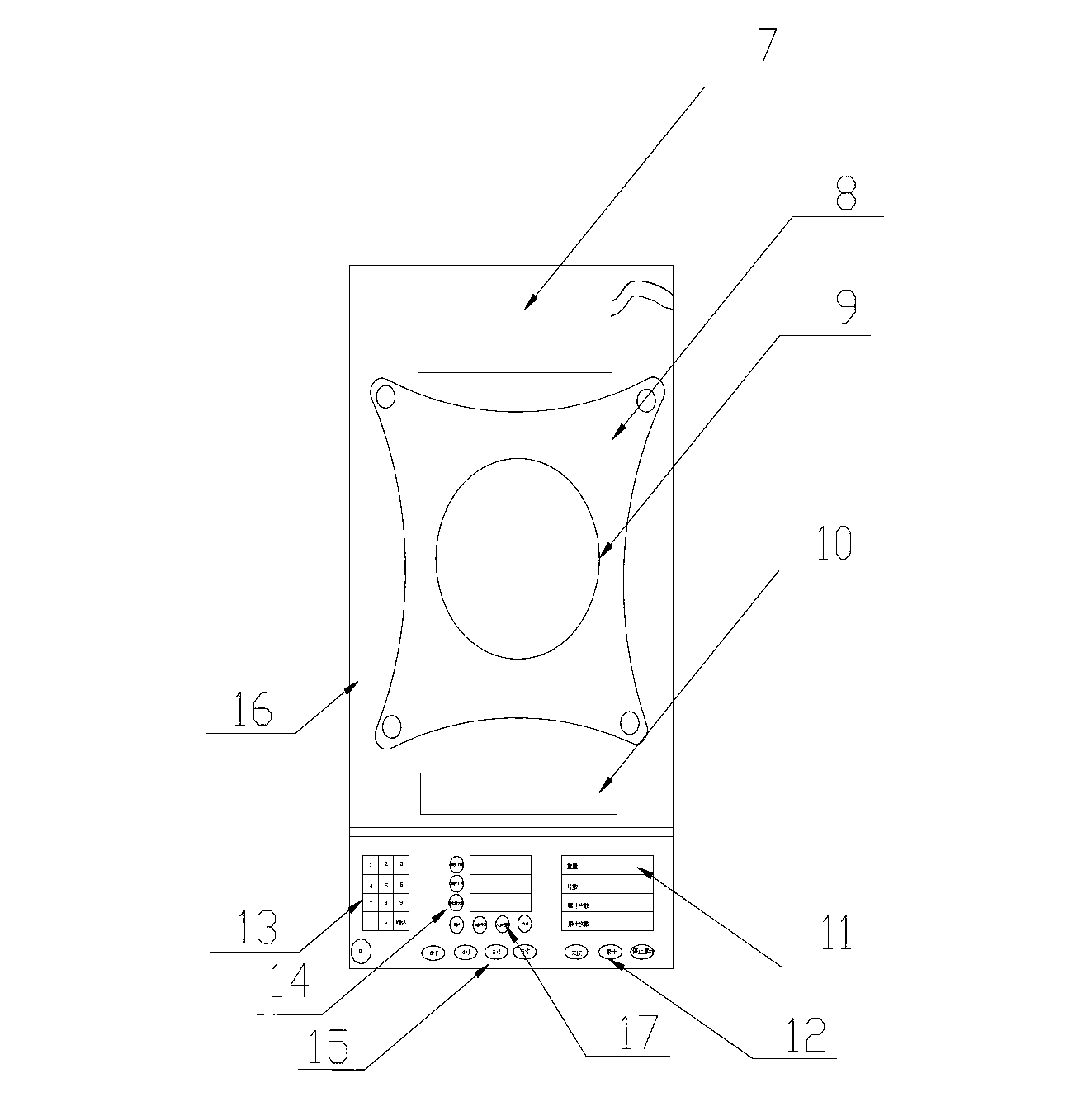

Embodiment 1

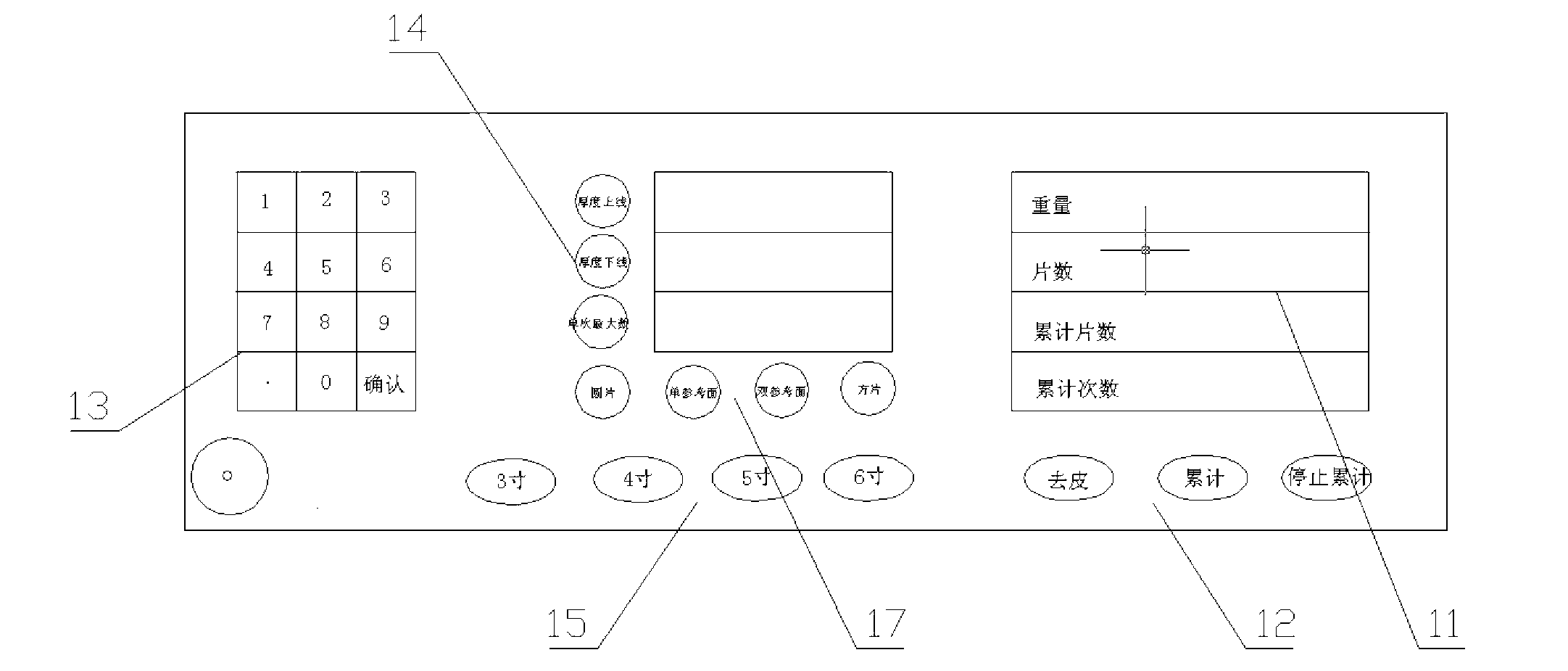

[0044] The actual use steps of the present invention: (with 285-290, 3-inch circular silicon wafers, 211pcs waiting for confirmation. According to the principle, the single maximum count n=56.)

[0045] 1. Turn on the switch of the device, and place the basket containing silicon wafers on the balance.

[0046] 2. When the display is stable, click Tare.

[0047] 3. Place the test weight on the basket and confirm that the weight display is consistent with the weight identification.

[0048] 4. Enter the silicon wafer thickness 285-290, and select "3 inches", "wafer".

[0049] 5. Put the wafers to be counted into the basket in batches, and click "Accumulate".

[0050] 6. If too many pieces are put in at one time, it will display "Exceeded" and will not be included in the cumulative number of pieces.

[0051] 7. Repeat steps 5-6 to get the final total number of pieces. Get "over", "56", "55", "over", "55", "45", respectively.

[0052] 8. "Accumulated number of pieces" display...

Embodiment 2

[0055] Shipment inspection, N14, 295-300 microns, 501pcs, wafers, 1pcs filter paper every 50pcs interval, of which 1 knife silicon wafer is 51pcs, the final inspection uses the device of the present invention for full inspection, and the final inspection requires 500pcs / box, 50pcs / Knife.

[0056] The inspection is as follows:

[0057] Testing frequency

Embodiment 3

[0059] 5-inch single reference surface, asymmetric chamfered silicon wafer, thickness 525-530 microns. The number of slices is unknown, and the number of slices is calculated using the device and method of the present invention.

[0060] 1. Input the upper and lower lines of the thickness to get the single maximum count value n=104pcs.

[0061] 2. Select the size "5 inches", "single reference plane", and press "cumulative" to count.

[0062] 3. Divided into multiple counts, respectively "52", "46", "68", "42", "45", a total of 253pcs.

[0063] 4. Checked by manual counting method, it is 253pcs, which is consistent with the result of the counting device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com