Silicon slice automatic slice counting method based on electronic balance

A technology of electronic balances and silicon wafers, used in measuring devices, instruments, weighing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

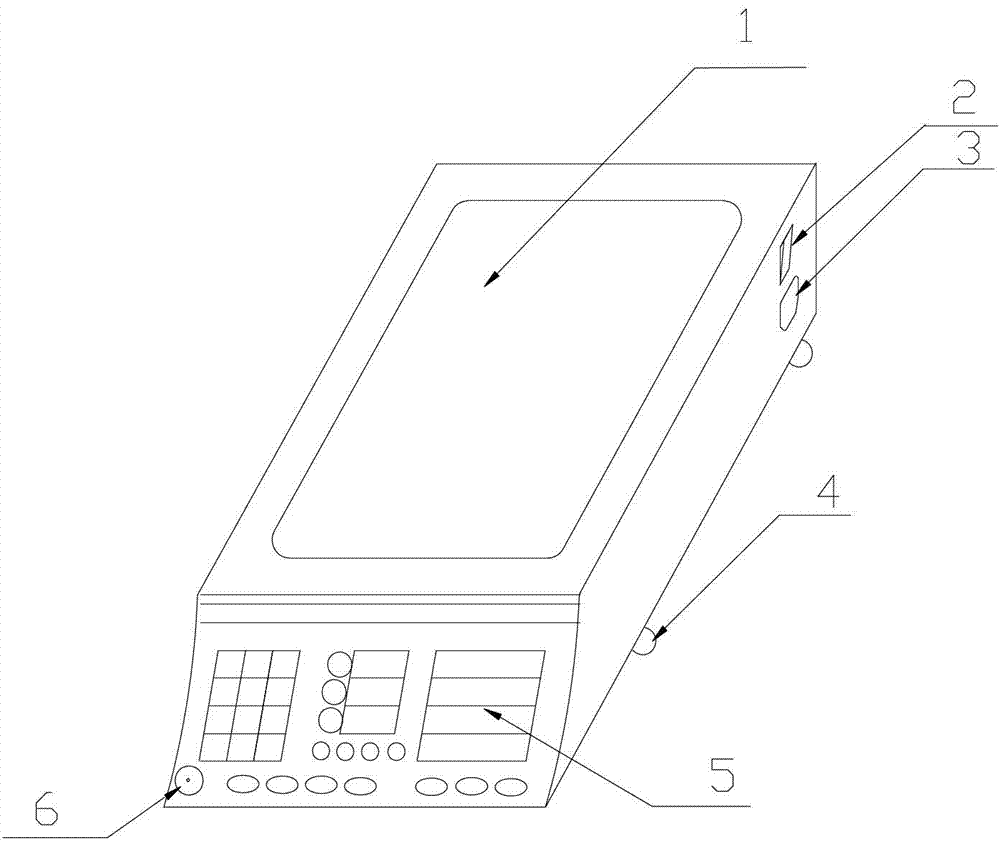

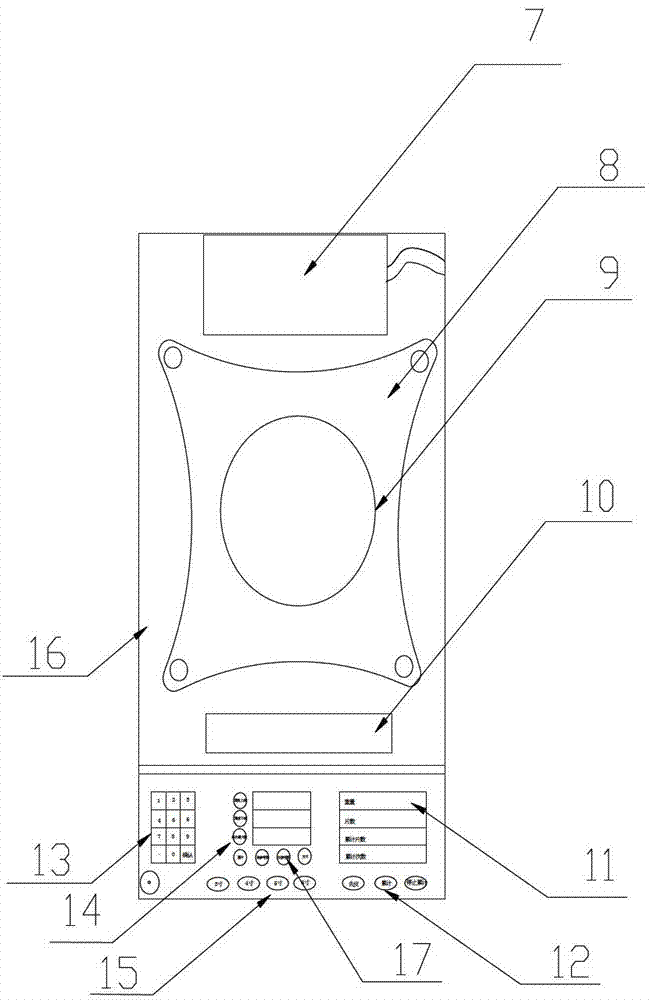

Image

Examples

Embodiment 1

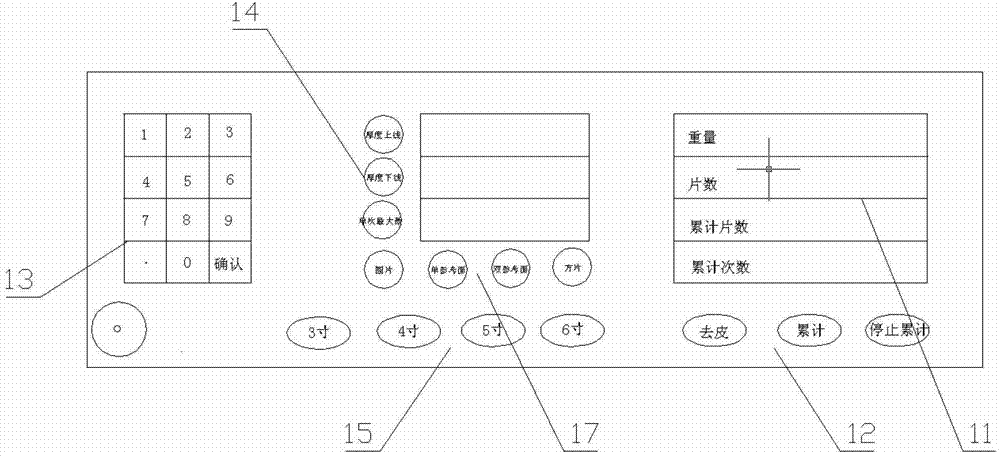

[0044] The actual use steps of the present invention: (Use 285-290, 3-inch round silicon wafers, 211pcs waiting for confirmation. According to the principle, the single maximum count n=56.)

[0045] 1. Turn on the switch of the device and place the basket containing the silicon wafers on the balance.

[0046] 2. When the display is stable, click Tare.

[0047] 3. Place the test weight on the basket and confirm that the weight display is consistent with the weight identification.

[0048] 4. Enter the thickness of the silicon wafer 285-290, and select "3 inch", "wafer".

[0049] 5. Put the wafers to be counted into the basket in batches, and click "Accumulate".

[0050] 6. If there are too many films inserted at one time, it will display "Exceeded" and will not be counted into the cumulative number of films.

[0051] 7. Repeat steps 5-6 to get the final total number of pieces. Get "exceeded", "56", "55", "exceeded", "55", "45" respectively.

[0052] 8. "Total number of pieces" displays 211...

Embodiment 2

[0055] Shipment inspection, N14, 295-300 microns, 501pcs, wafers, 1pcs filter paper per 50pcs interval, of which 51pcs for 1 slice of silicon wafers, the final inspection piece number is fully inspected using the device of the invention, the final inspection requires 500pcs / box, 50pcs / Knife.

[0056] The inspection conditions are as follows:

[0057] Testing frequency

Embodiment 3

[0059] 5-inch single reference surface, asymmetrical chamfered silicon wafer, thickness 525-530 microns. The number of slices is unknown, and the device and method of the present invention are used to calculate the number of slices.

[0060] 1. Enter the thickness upper and lower line, and get the single maximum count value n=104pcs.

[0061] 2. Select the size "5 inch", "single reference surface", and press "cumulative" to count.

[0062] 3. It is counted multiple times, which are "52", "46", "68", "42", and "45" for a total of 253pcs.

[0063] 4. It is checked by manual counting method, which is 253pcs, which is consistent with the result of the counting device.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com