Stable shearing tension force setting method

A tension setting and stabilization technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as unstable shearing process, burrs, strip vibration, etc., and reduce the incidence of burrs and other defects , reduce mutations and increase stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

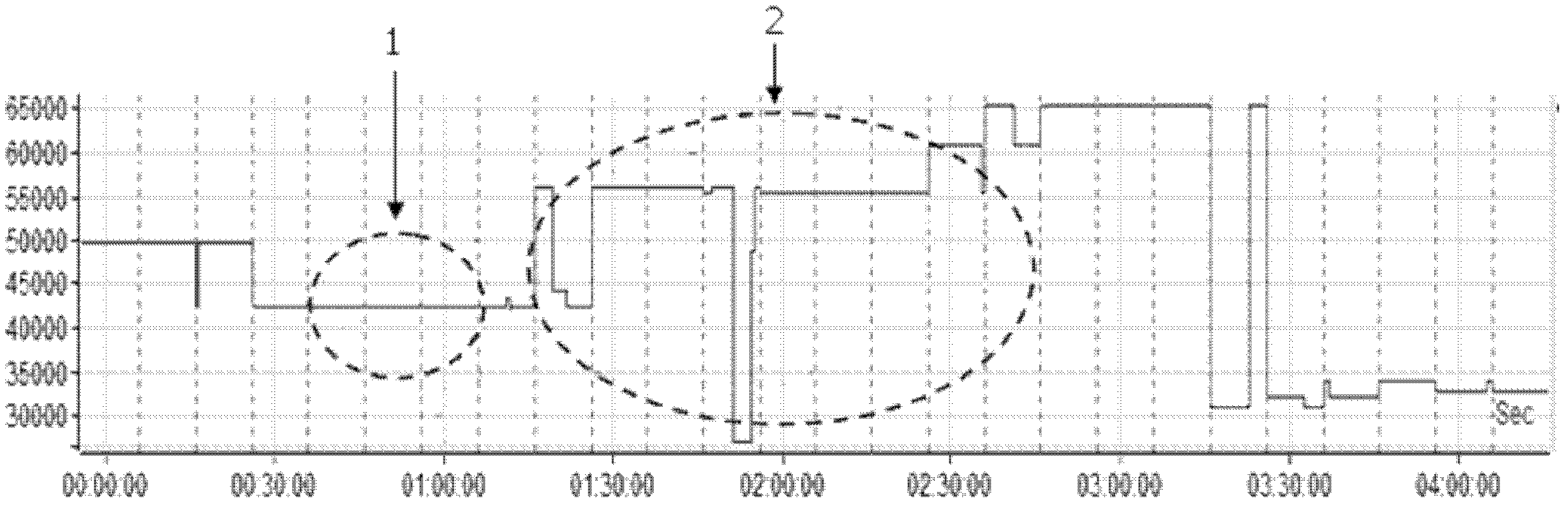

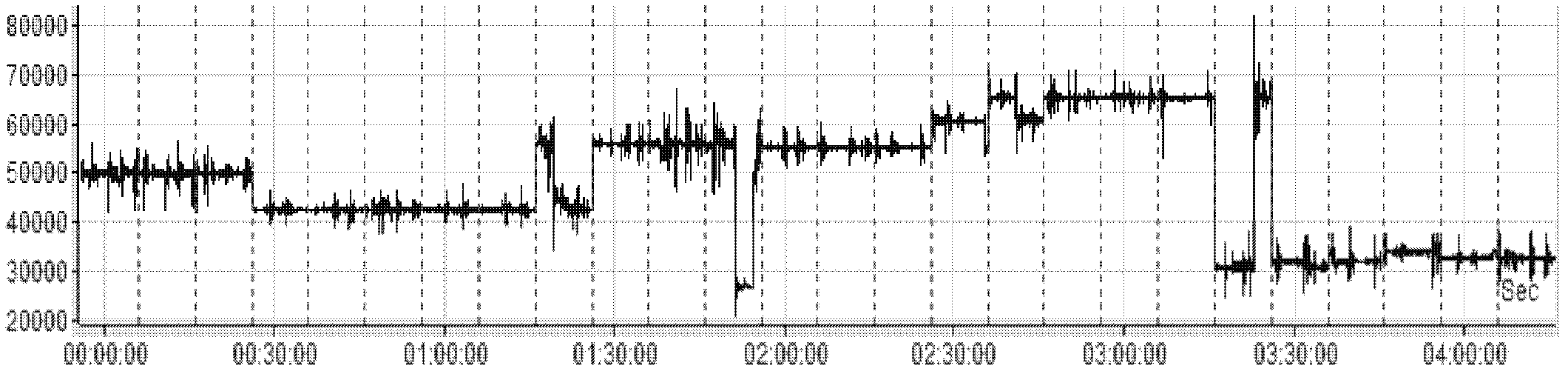

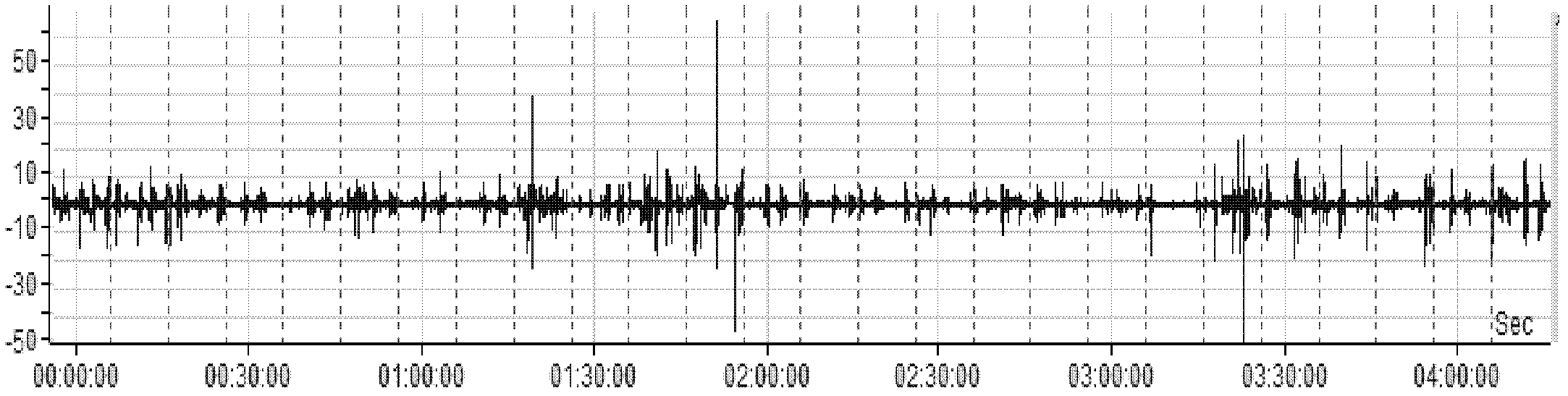

[0041] figure 2 Disclosed is a stable shear tension setting method according to an embodiment of the present invention, which is suitable for the disk shear specification process of an acid rolling mill. The tension setting method 200 includes:

[0042] 201. Select N steel coils to be cut. In one embodiment, the value of N is N≥2.

[0043] 202. Collect characteristic parameters of the N steel coils. In one embodiment, the characteristic parameters include: strip width B i , strip thickness h i , strip strength σ si . where strip width B i and strip thickness h i Reflecting specification changes, strip strength σ si Indicates steel grade change.

[0044] 203. Importing tension setpoint allows adjustment coefficient α. In one embodiment, the value range of the tension setting value allows the adjustment coefficient α to be between 0.03-0.15.

[0045] 204. Set the current steel coil number as i=1, corresponding to the first coil among the N steel coils, and set the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com