Welding-with-trailing impact rolling welded seam shaping device for welded joint

A technology of impact and shaping device with welding, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of large volume of air hammer equipment, unfavorable operation of equipment, large labor load, etc., to improve welding quality and save manpower , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

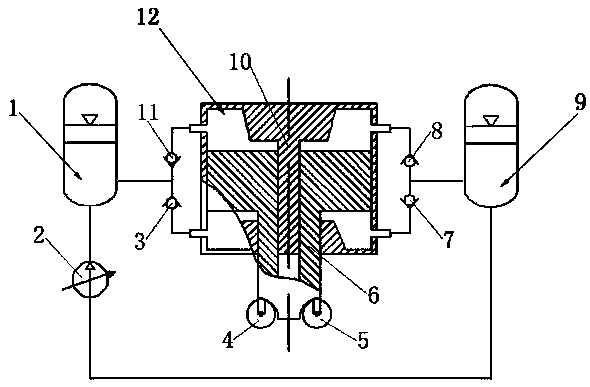

[0020] Example: Control Figure 1~3

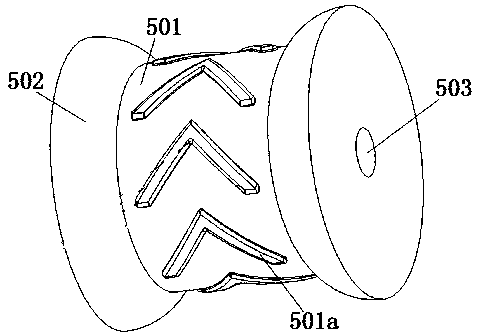

[0021] A welding seam shaping device for welding impact rolling with welding, including a vibration expansion device, a main rolling wheel 5 and an auxiliary rolling wheel 4 fixedly arranged at the bottom of the vibration expansion device, the main rolling wheel 5 and the auxiliary rolling wheel 4 on the same level.

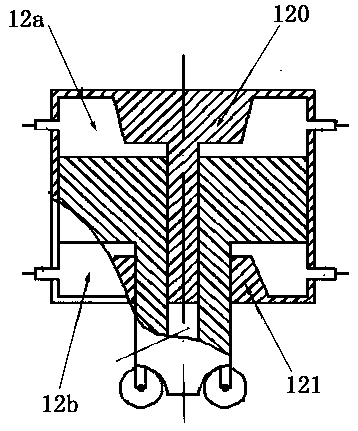

[0022] The vibration telescopic device includes a hydraulic chamber 12, a T-shaped piston 6, a hydraulic pump 2, a high-pressure oil reservoir 1, a low-pressure oil reservoir 9 and a central shaft 10, and the central shaft 10 is fixed vertically in the hydraulic chamber 12 . The center of the T-shaped piston 6 is provided with a cylindrical hollow through-hole matching the outer diameter of the central shaft 10, the T-shaped piston 6 is fitly sleeved on the outside of the central shaft 10, and the upper end of the T-shaped piston 6 is fitted in the hydraulic chamber 12 and Divide the hydraulic chamber 12 into upper and low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com