Cold end and hot end separated type thermoelectric refrigeration semiconductor technology

A technology of thermoelectric refrigeration and N-type semiconductors, which is applied to thermoelectric devices that only use the Peltier or Seebeck effect, can solve the problem that the cold end and the hot end cannot be separated at a long distance, and achieve convenient forced cooling, small thermal conductivity, and Simplify the effect of insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

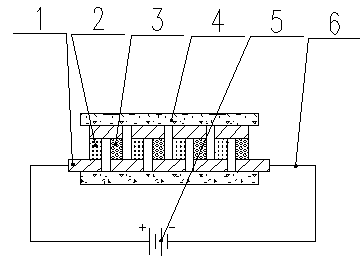

[0020] Embodiment 1: as figure 2 As shown, the method for connecting cold-end and hot-end separated thermoelectric cooling semiconductors includes copper connecting pieces (1), N-type semiconductors (2), P-type semiconductors (3), DC power supplies (5), wires (6 ). The current from the positive pole of the DC power supply (5) is connected through the wire (6), and then passes through the copper connecting piece (1)-N-type semiconductor (2)-copper connecting piece (1)-wire (6)-copper connecting piece ( 1)-N-type semiconductor (2)-copper connection sheet (1)-P-type semiconductor (3)-copper connection sheet (1)-wire (6)-P-type semiconductor (3)-copper connection sheet (1)- Wire (6) - the negative pole of the DC power supply (5); the NNPP junction in the above series circuit absorbs heat at the NP end and releases heat at the PN end. Although this connection method is used for thermoelectric cooling, it can also be used for thermoelectric power generation when the DC power supp...

Embodiment 2

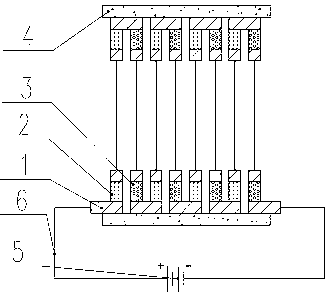

[0021] Embodiment 2: as image 3 As shown, the connection method of the thermoelectric cooling semiconductor with separated cold end and hot end includes a copper connecting piece (1), an N-type semiconductor (2), a P-type semiconductor (3), a heat-conducting ceramic piece (4), a DC power supply (5), wire (6). The current from the positive pole of the DC power supply (5) passes through the connection of the wire (6), and then passes through multiple copper connection pieces (1)-N-type semiconductor (2)-copper connection piece (1)-wire (6)-copper connection Sheet (1)-N-type semiconductor (2)-copper connection sheet (1)-P-type semiconductor (3)-copper connection sheet (1)-wire (6)-P-type semiconductor (3) in series to form an NNPP junction, Heat is absorbed at the NP end and released at the PN end, so a cold end is formed on the upper heat-conducting ceramic sheet (4), and a hot end is formed on the lower heat-conducting ceramic sheet (4). Although this connection method is us...

Embodiment 3

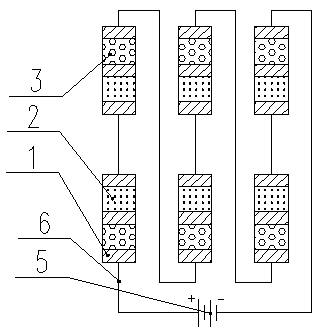

[0022] Embodiment 3: as Figure 4 As shown, the cold-end and hot-end separation type thermoelectric cooling semiconductor series connection method includes copper connecting piece (1), N-type semiconductor (2), P-type semiconductor (3), DC power supply (5), wire (6 ). The current from the positive pole of the DC power supply (5) is sequentially connected through wires (6), and multiple copper connection pieces (1)-P-type semiconductor (3)-copper connection piece (1)-N-type semiconductor (2)-copper connection Sheet (1)-wire (6)-copper connection sheet (1)-N-type semiconductor (2)-copper connection sheet (1)-P-type semiconductor (3)-copper connection sheet (1) in series to form a PNNP junction, Heat is absorbed at the NP side and released at the PN side. The series circuit can be easily made into electric cooling quilt, electric cooling cap, electric cooling bag, etc., the hot end is placed outside the bag (or quilt, cap) to dissipate heat, and the cold end is placed inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com