Ultrasonic flow rate measurement unit

A flow measurement and ultrasonic technology, applied in the field of ultrasonic flow measurement unit, can solve the problems of high price and troublesome installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

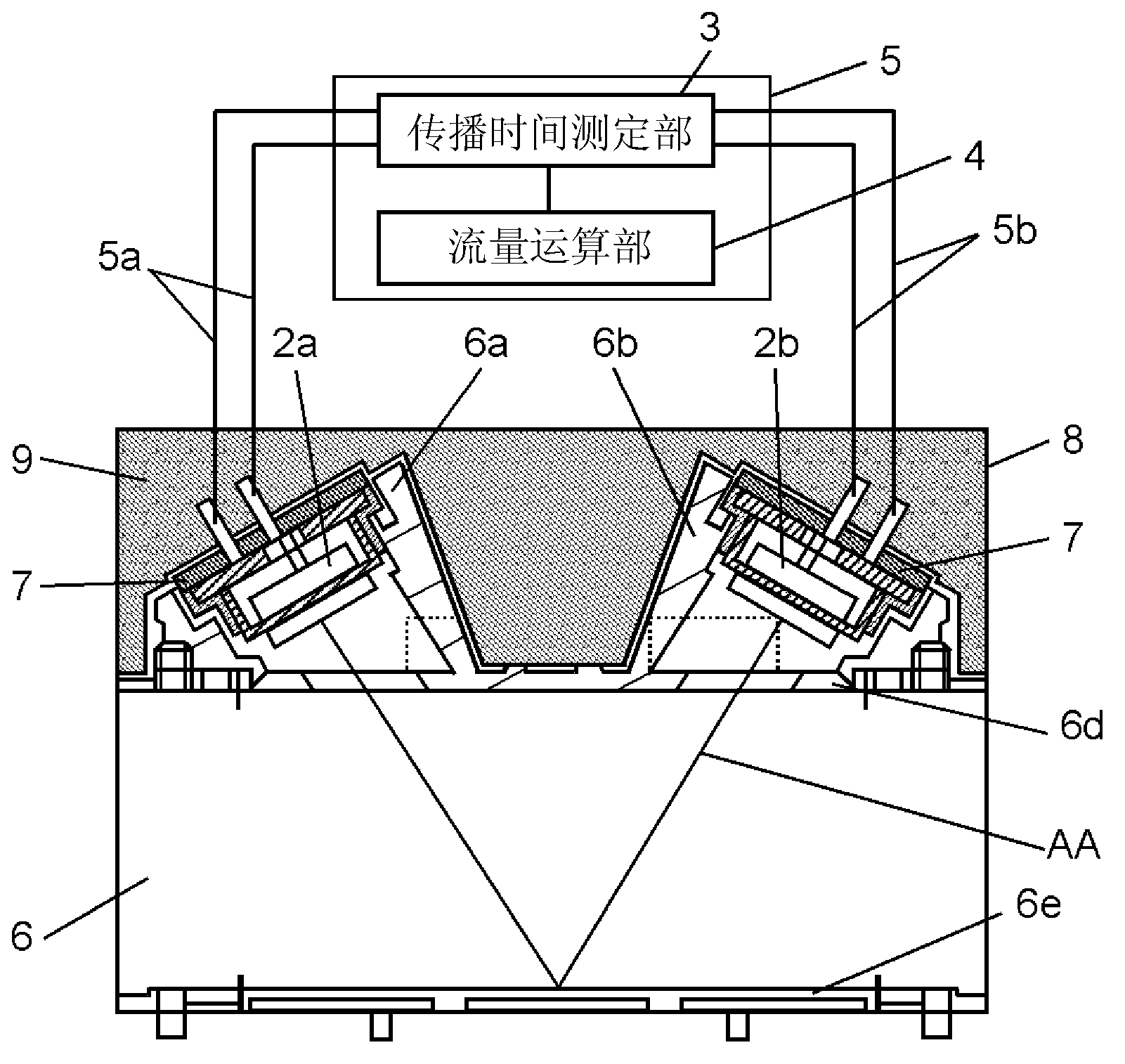

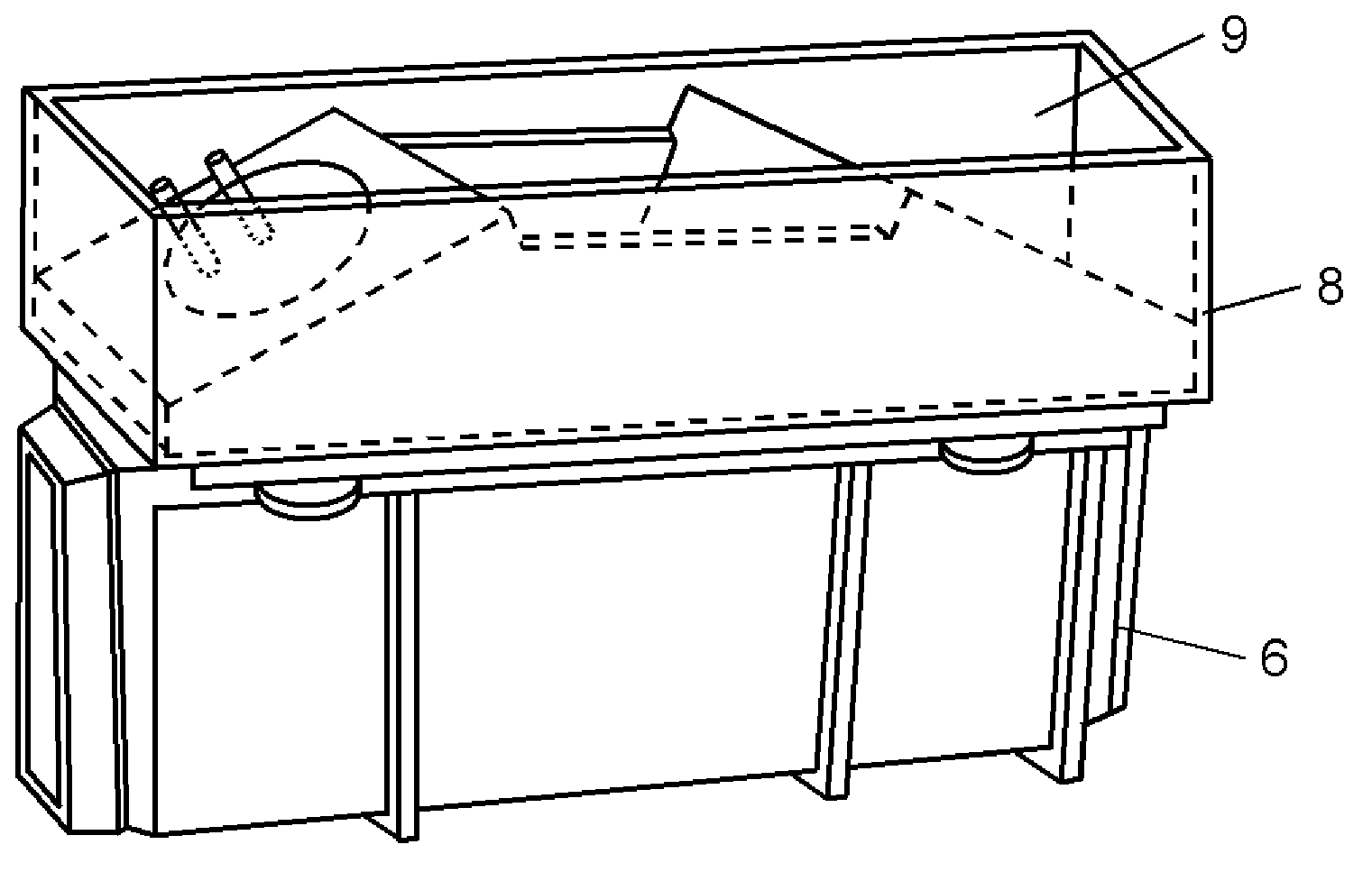

[0015] Below, use Figure 1A and Figure 1B The ultrasonic flow rate measurement unit according to Embodiment 1 of the present invention will be described. Figure 1A It is a cross-sectional view of the ultrasonic flow rate measurement unit according to Embodiment 1 of the present invention. Figure 1B It is a perspective view of the ultrasonic flow rate measurement unit of this embodiment.

[0016] like Figure 1A and Figure 1B As shown, the ultrasonic flow measurement unit is composed of at least a measurement channel 6, a pair of ultrasonic vibrators 2a and 2b accommodated in a housing 8, a measurement circuit board 5, and a vibration damping member 9 made of a vibration damping material. The measurement circuit board 5 includes a propagation time measurement unit 3 connected to a pair of ultrasonic transducers 2a, 2b via lead wires 5a, 5b, and a flow calculation unit 4. In the case 8, a vibration damping member 9 is filled to cover the pair of ultrasonic vibrators 2a...

Embodiment approach 2

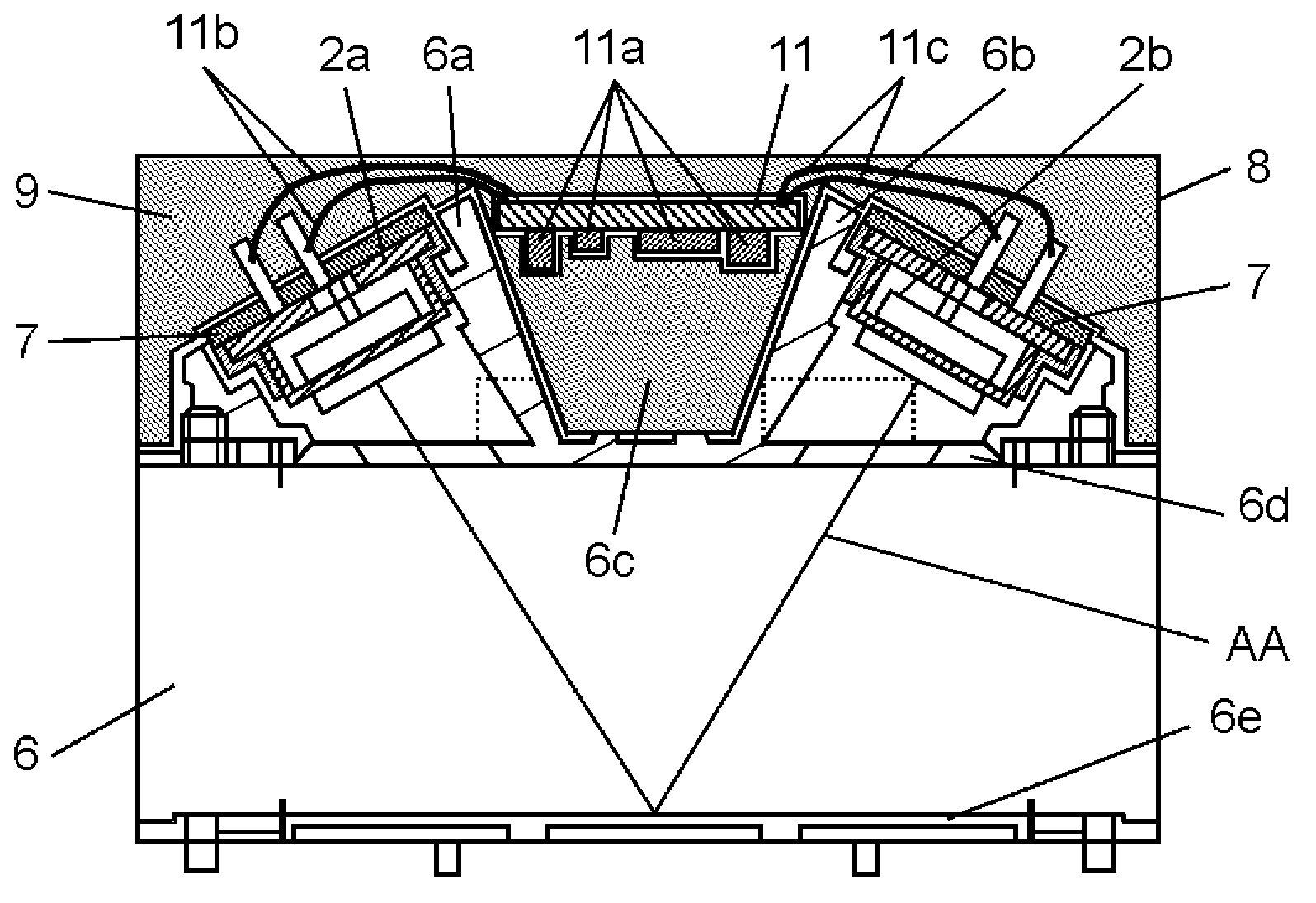

[0025] Below, use Figure 2A and Figure 2B An ultrasonic flow rate measurement unit according to Embodiment 2 of the present invention will be described. Figure 2A It is a cross-sectional view of the ultrasonic flow rate measurement unit according to Embodiment 2 of the present invention. Figure 2B It is a perspective view of the ultrasonic flow rate measurement unit of this embodiment.

[0026] like Figure 2A and Figure 2B As shown, the difference between the ultrasonic flow measurement unit of the present embodiment and the first embodiment is that the measurement circuit board 11 is arranged between the pair of ultrasonic vibrators 2a, 2b and stored in the housing 8, and the vibration-damping member 9 is used to cover the measurement unit. A circuit board 11 and a pair of ultrasonic vibrators 2a, 2b. The other structures and functions are basically the same as those in Embodiment 1, and therefore descriptions thereof are omitted.

[0027] That is, if Figure 2A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com