Processing molds for sheet metal pipe clamps

A technology for processing molds and metal sheets, which is applied in the field of processing molds for sheet metal pipe clamps, can solve the problems of elongation, warping and deformation of parts, and time-consuming and labor-intensive manual demoulding, so as to achieve accurate guiding and positioning, reduce bending force, and reduce friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

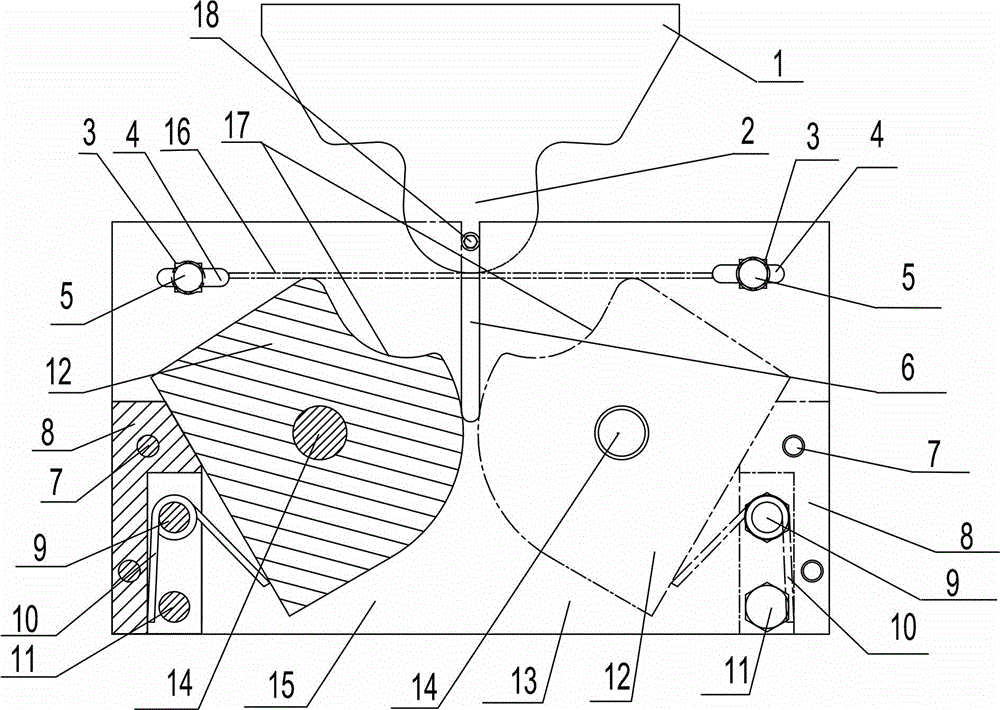

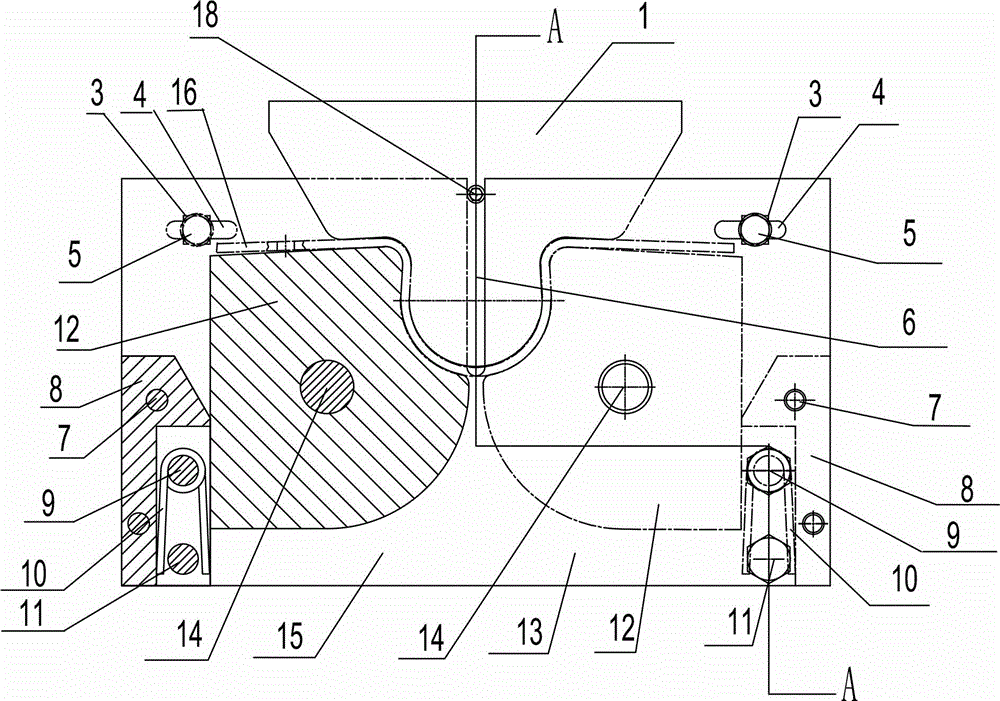

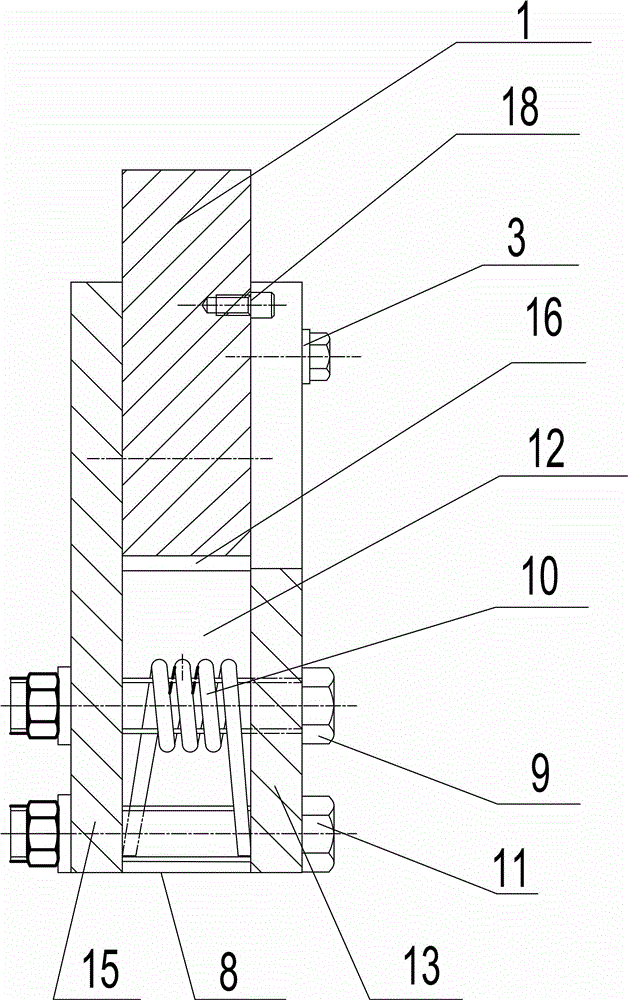

[0014] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, this embodiment includes an upper mold 1, a lower mold, a support positioning seat, a blank fixing assembly and a rebound limiting assembly. The upper die 1 is a convex die whose upper part is in the shape of an inverted cone, and the protruding part 2 of the lower part is the same as the internal shape of the processed part concave part. The lower mold is made up of the same shape, two recessed parts 17 after splicing symmetrically distributed and the same half-die 12 with the same external shape of the processed part concave part. The thickness of the upper mold 1 and the thickness of the lower mold are not less than the thickness of the blank. After the two are combined, the gap between them is the shape of the processed part. The support positioning seat is made up ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com