Lifting platform for underground cable construction

A technology for underground cables and lifting platforms, applied in the direction of lifting devices, etc., can solve the problems of unstable power supply, labor consumption and labor consumption in remote areas, and achieve the effect of avoiding platform falling accidents, being convenient for use, and improving construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

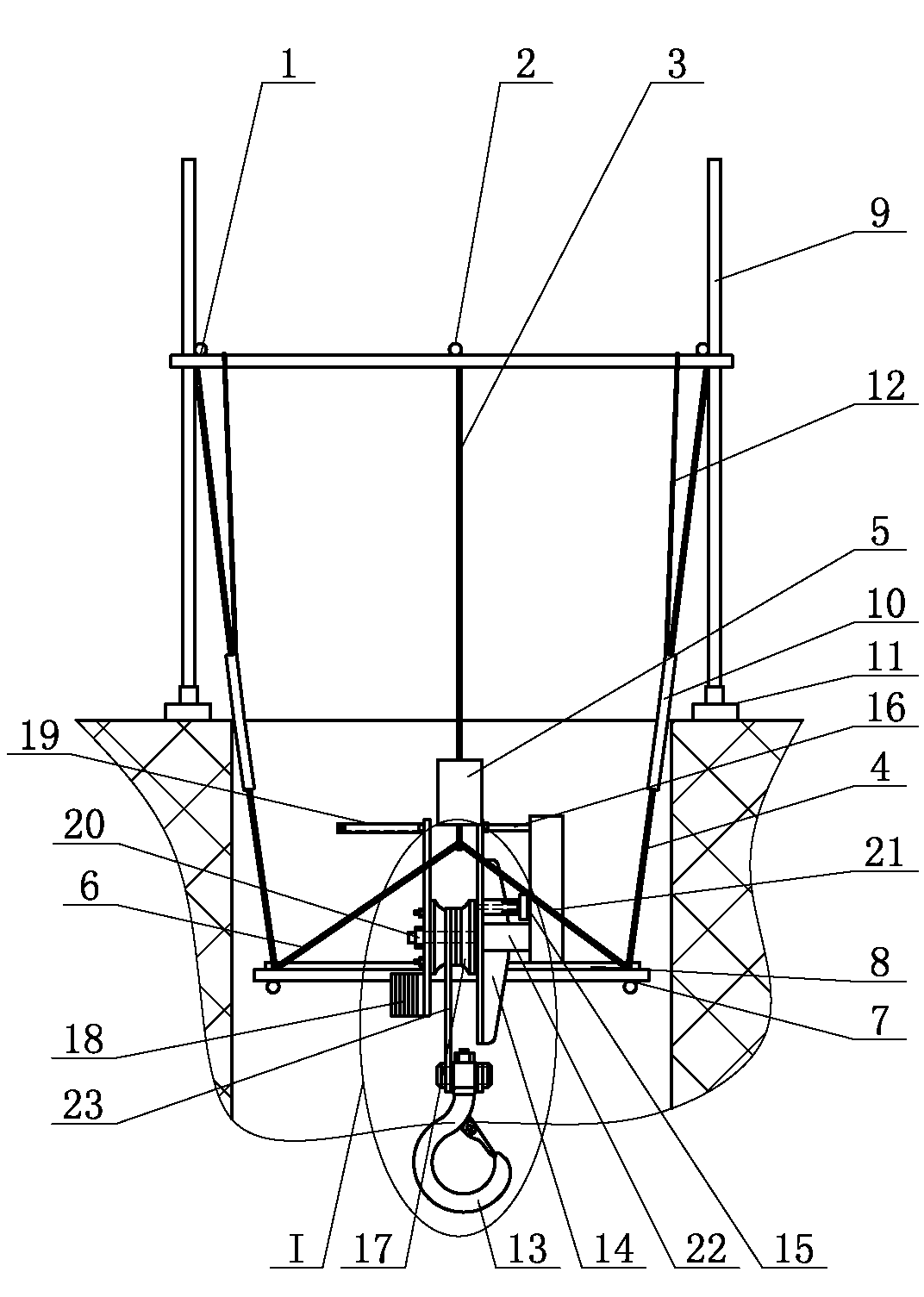

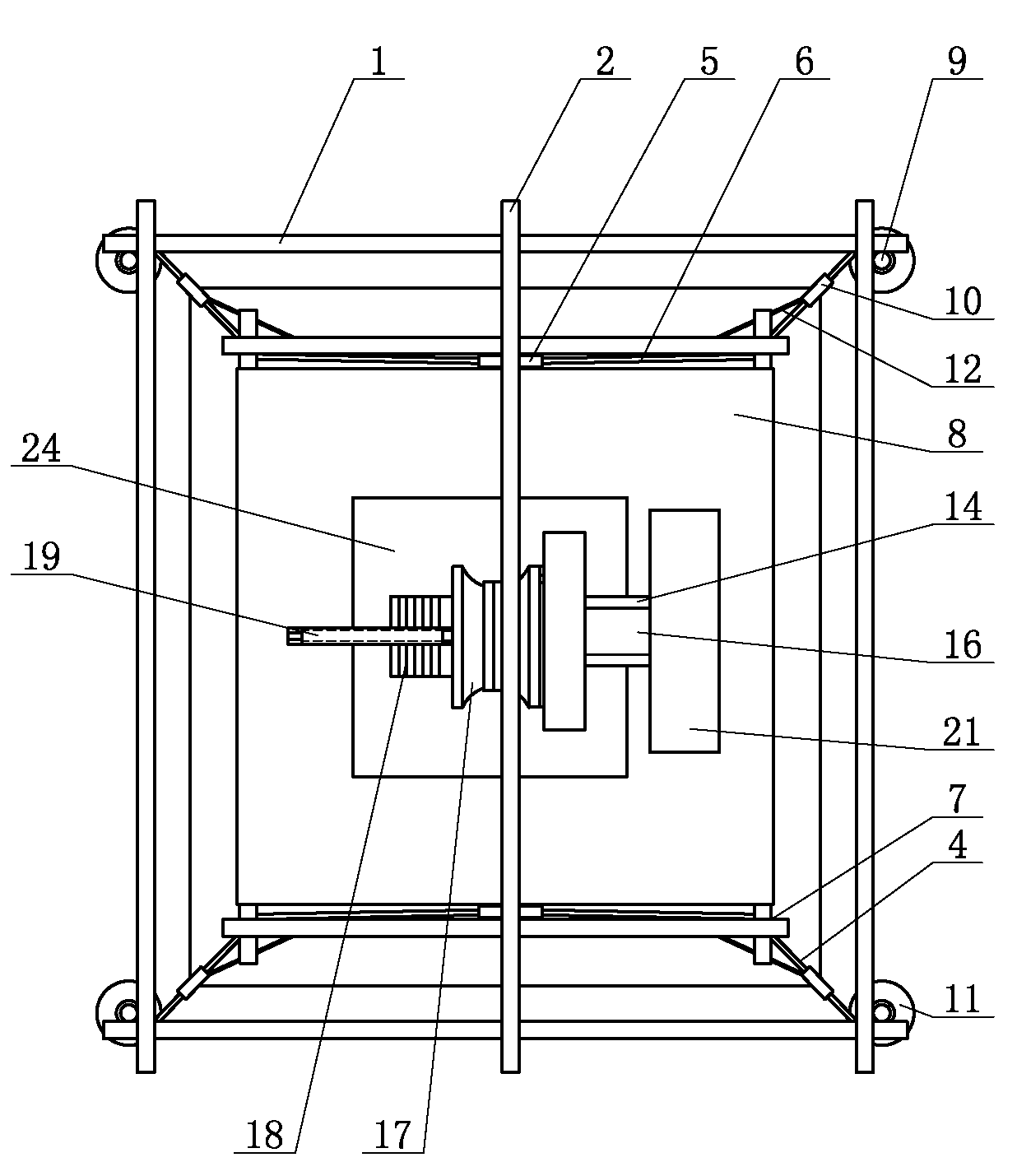

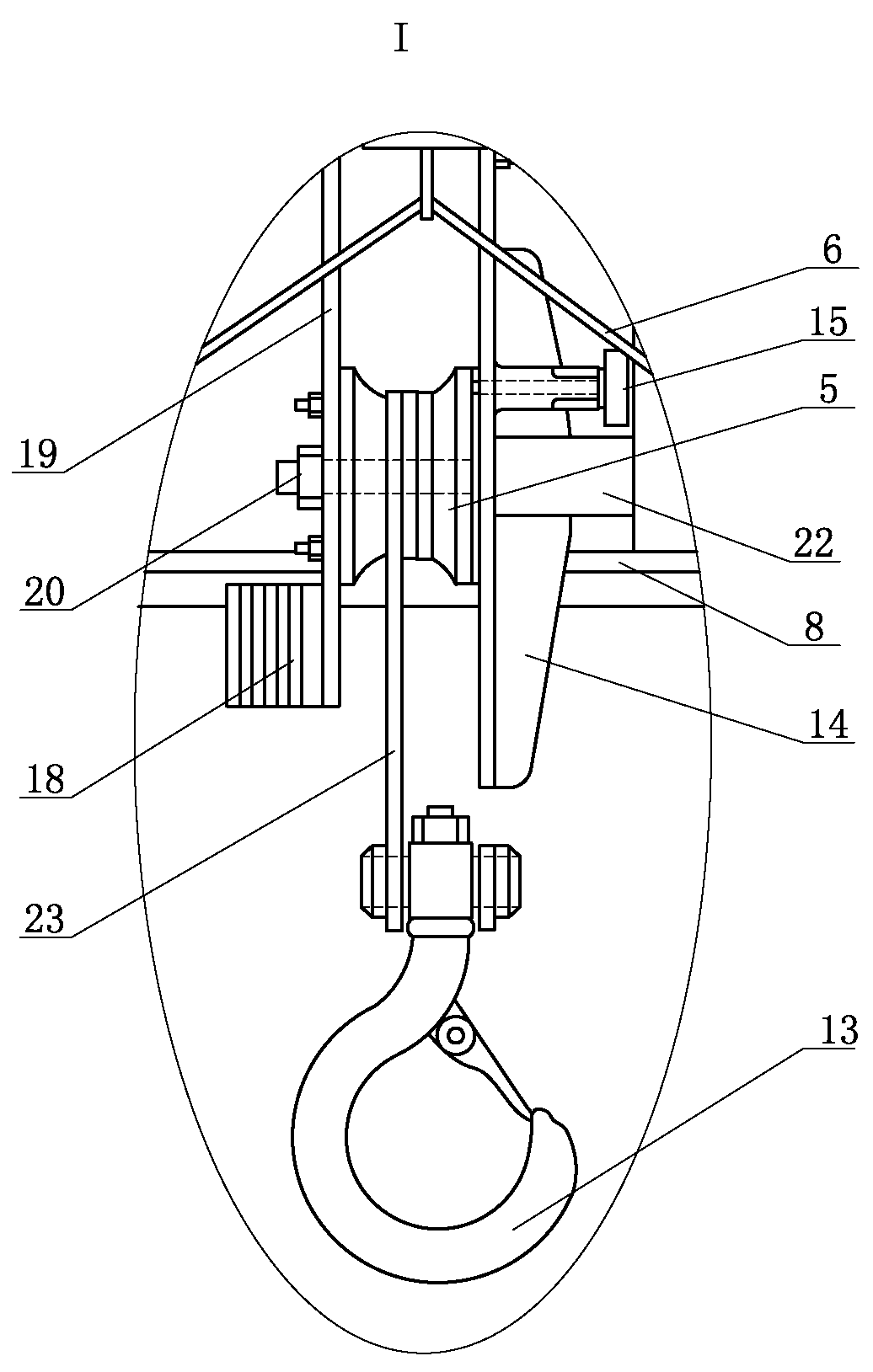

[0009] The lifting platform for underground cable construction includes four outriggers 9, a bracket 1 is installed on the four outriggers 9, a horizontal tube 2 is installed on the bracket 1, a suspension rope 3 is respectively arranged at both ends of the horizontal tube 2, and the upper end of the suspension rope 3 is fixed on On the horizontal pipe 2, a lever hoist 5 is arranged at the lower end of the suspension rope 3, and the upper end of the lever hoist 5 is connected with the suspension rope 3, and the lower end of the lever hoist 5 is provided with two sections of fixed ropes 6, and the lower end of the two sections of fixed ropes 6 is provided with a platform frame 7. A stay rope 4 is respectively arranged on the four connection nodes of the support 1, the upper end of the stay rope 4 is connected with the support 1, the lower end of the stay rope 4 is connected with the platform frame 7, and the stay rope 4 connects the platform frame 7 with the support 1, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com