Non-metal expansion joint for slag discharge pipeline of boiler

A slag discharge pipe, non-metal technology, applied in pipeline expansion compensation devices, pipe components, pipeline protection and other directions, can solve the problem of the difficulty of maintaining uniform distribution of the insulation layer, the decline of the insulation effect, the cavity of the insulation layer, etc. problems, to achieve the effect of ensuring long-term effective operation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

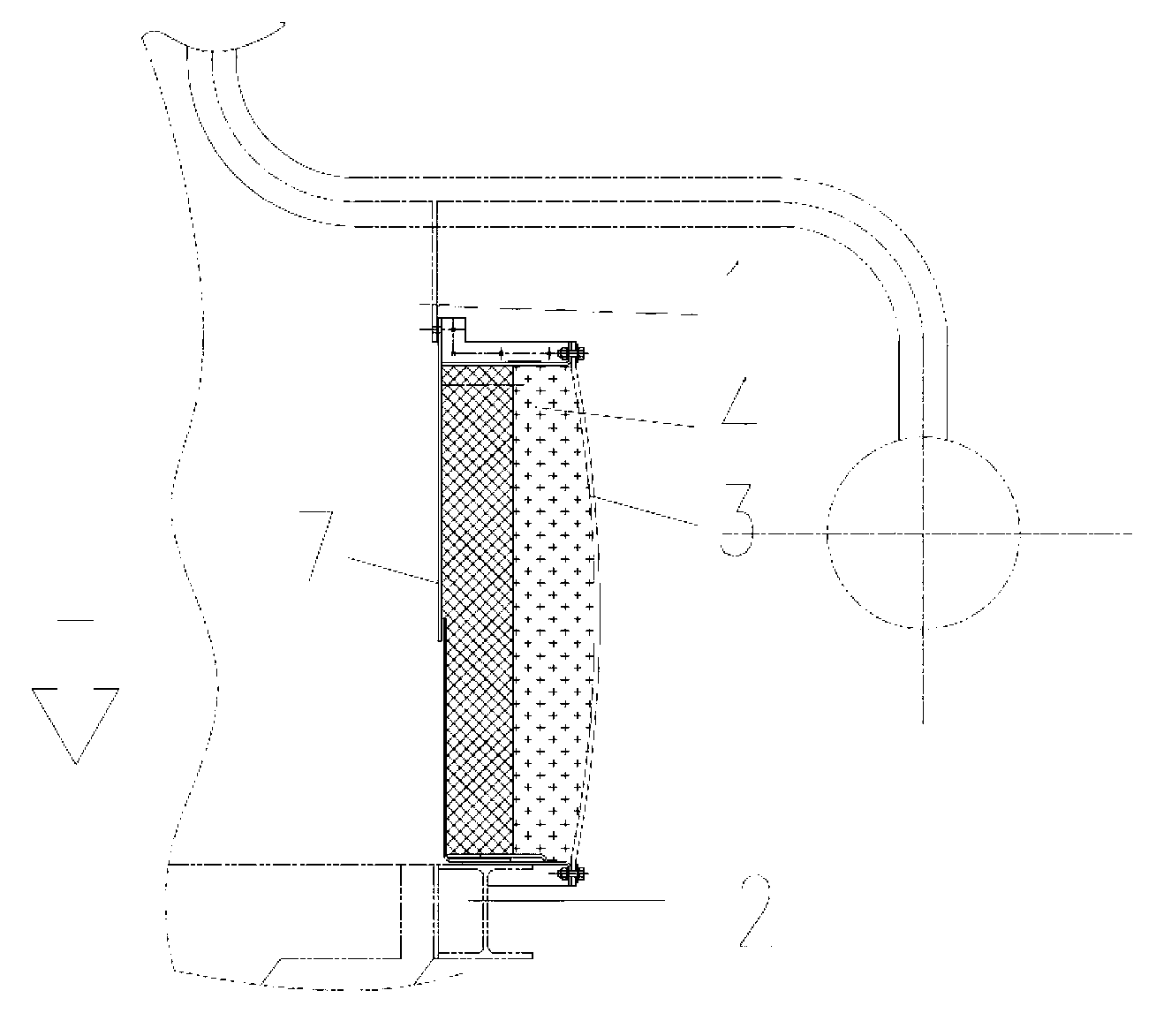

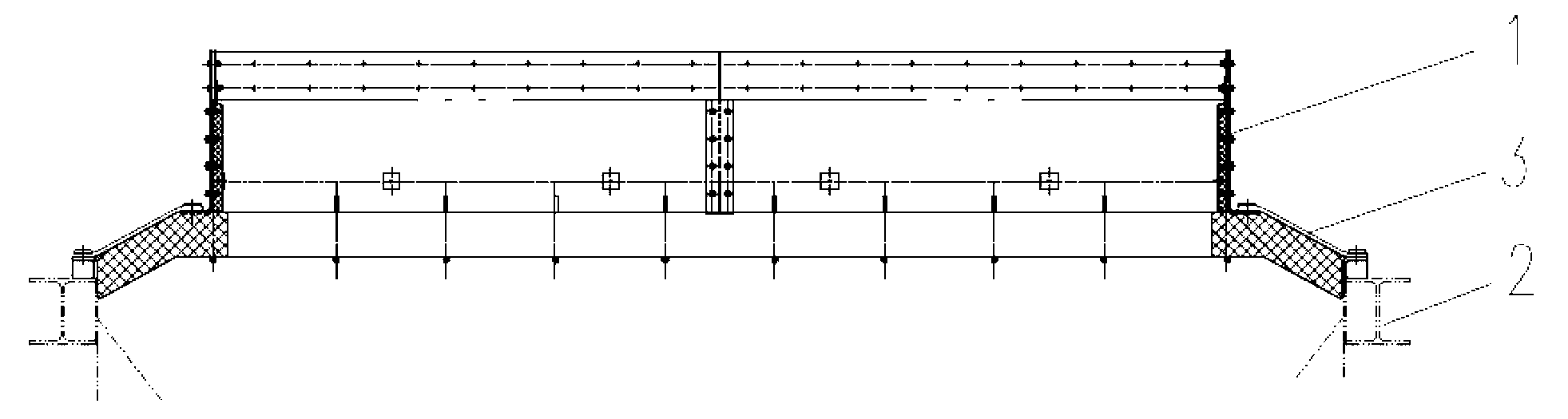

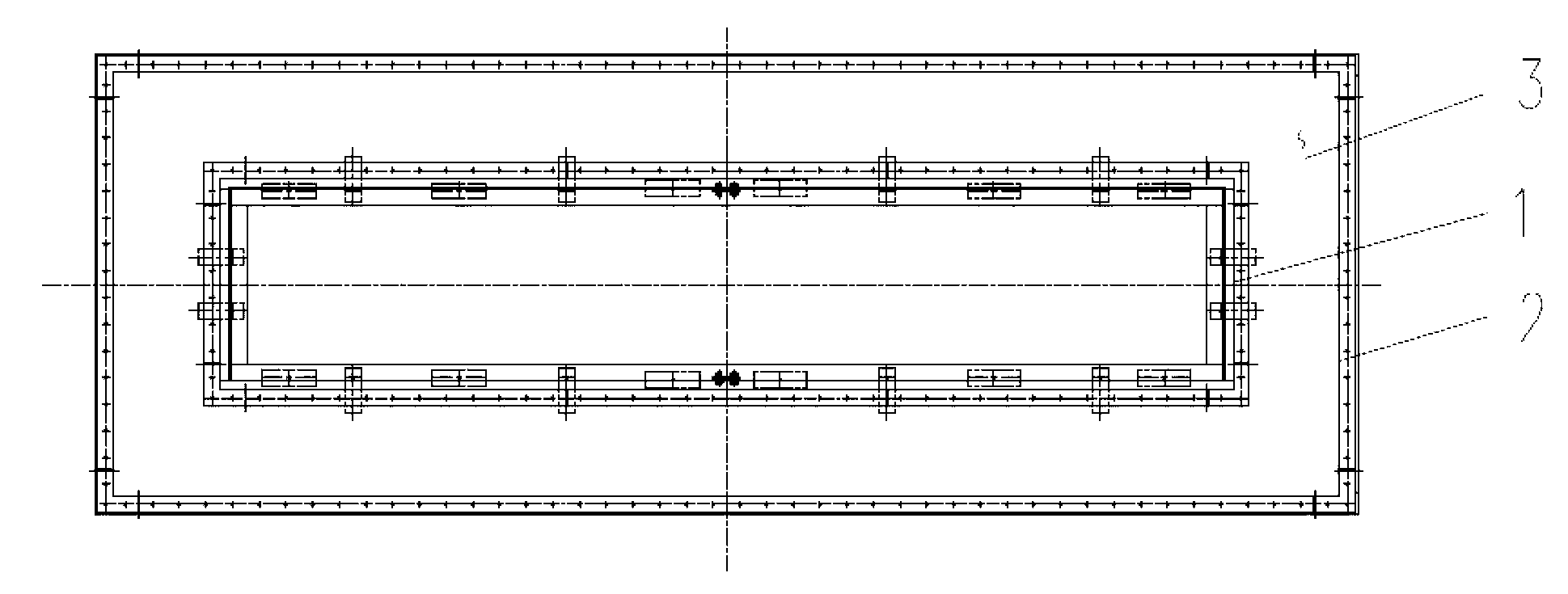

[0014] The non-metallic expansion joint of the boiler slag discharge pipeline in this embodiment is as attached figure 2 As shown, it includes a rectangular upper frame 1 and a lower frame 2 respectively connected to the upper pipeline and the lower pipeline; the flow section of the upper frame 1 is smaller than the flow section of the lower frame 2, and the two circles are equally spaced, and the distance between them is axial About 1.2 times of the displacement (1-1.5 times can make the inclination angle of the flexible ring belt less than 45 degrees when the axial position is located, and the effect is better). The 1st circle of the upper frame has a lower horizontal flange, the 2nd circle of the lower frame has an upper horizontal flange, and the upper horizontal flange and the lower horizontal flange are fixed "back" by the outer peripheral pressure plate 5 Zigzag flexible ring belt 3, the inner side of flexible ring belt 3 is fixed temperature-resistant fiber blanket (c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com