Pearlite spheroidization grading method based on contour tracing

A technology of contour tracking and grading method, which is applied in the direction of material analysis, analysis material, and measuring device by optical means, which can solve the problems of being easily interfered by human factors and difficult to realize automatic grading of computer pearlite metallographic photos, etc. Reduce human interference, improve accuracy and automation, consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

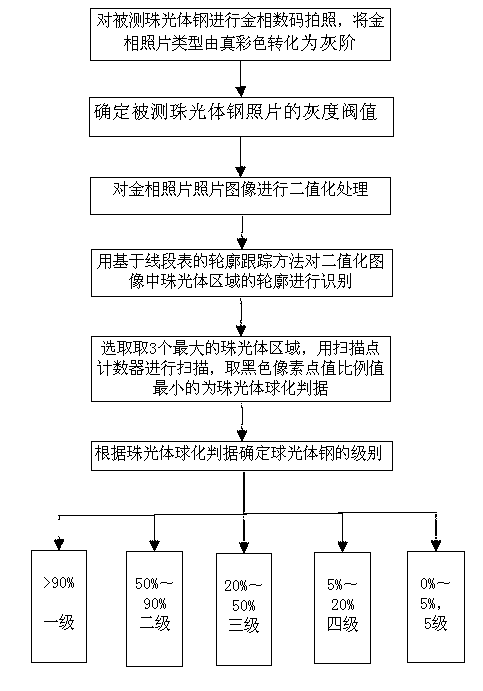

[0020] The present invention is based on contour tracking to the grading method of pearlite spheroidization, such as figure 1 shown, including the following steps:

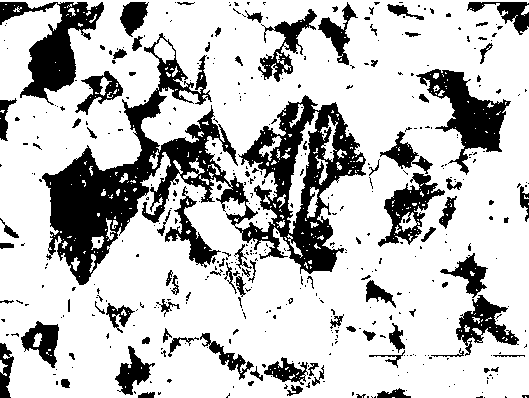

[0021] Use the Olympus inverted metallographic microscope (model PMG3-613U) with a digital camera with a metallographic camera system (resolution 1024*768) to take metallographic digital photos of the boiler heating surface tubes. The material of the boiler heating surface tubes It is 12Cr1MoV steel. Read the photo into the computer memory, record the file name of the photo, and convert the photo type from true color to grayscale. The metallographic photo image is as follows: figure 2 shown.

[0022] Determine the grayscale threshold of the pearlitic steel photo to be tested. The gray threshold value is the threshold value of the photo, which is the minimum value among the threshold values calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com