Intelligent sintering mixed water adding control method with prediction function

A control method and functional technology, which is applied in the field of intelligent sintering mixed water addition control, can solve the problems of increased workload, control system disturbance, and large amount of ore return, and achieve the effects of increasing control accuracy, reducing system disturbance, and strong portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

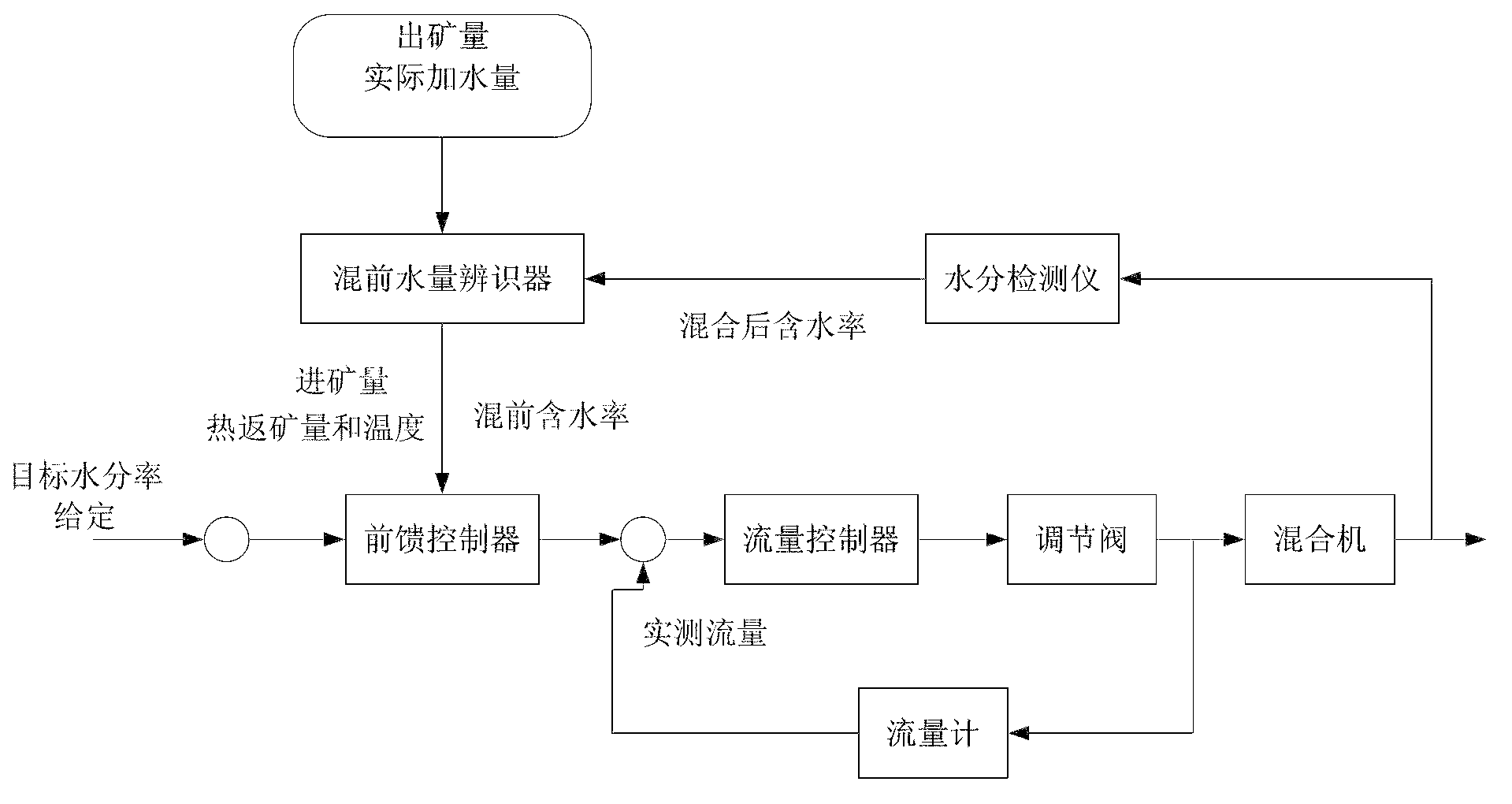

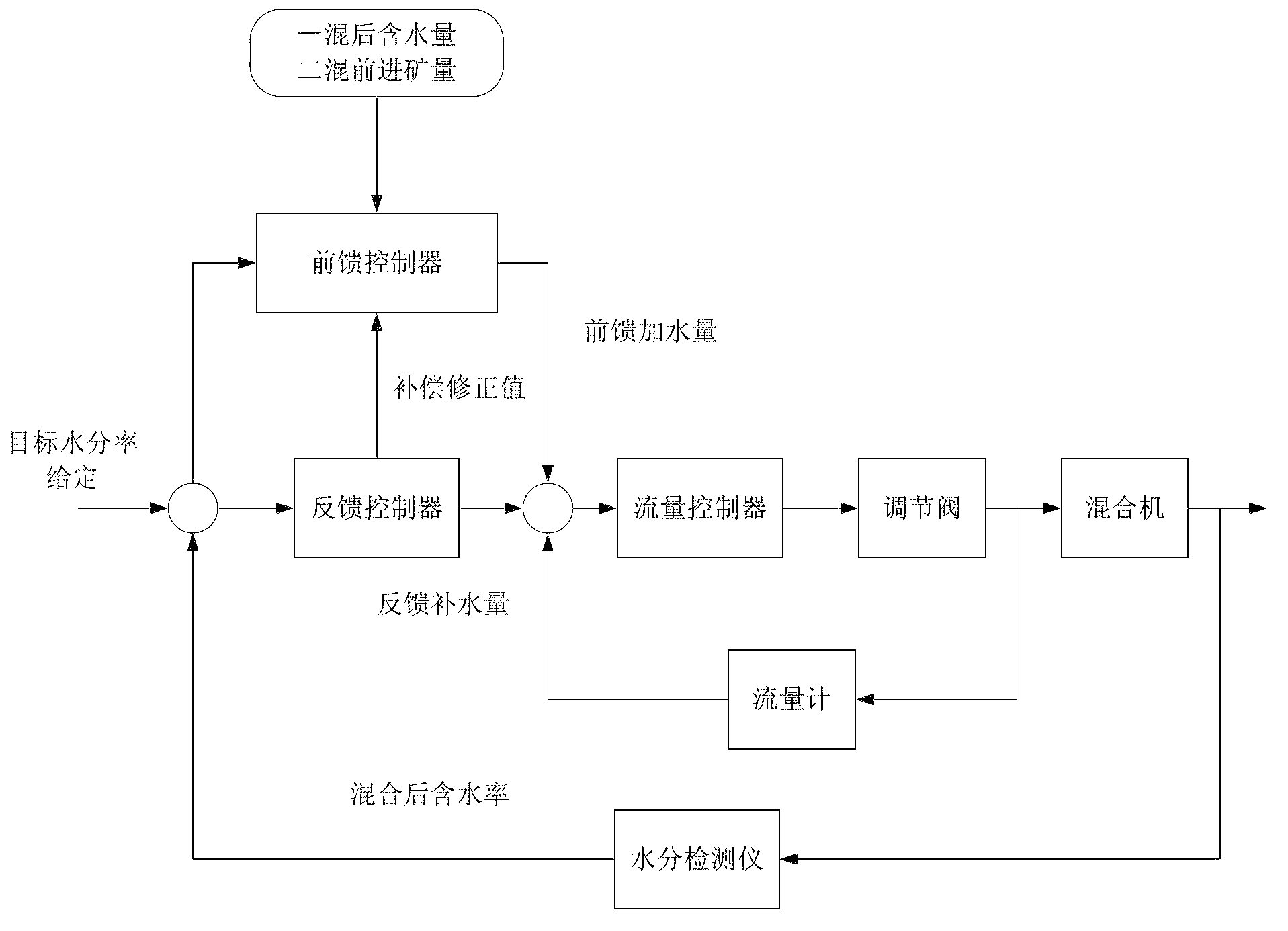

[0034] An intelligent sintering mixing water addition control method with predictive function, the method adopts different control methods for primary mixing and secondary mixing, primary mixing adopts feedforward control mode with identification and prediction functions, and secondary mixing adopts feedforward feedback compound way to control.

[0035] See figure 1 , The primary mixing control device includes a pre-mixing water volume identifier, a feedforward controller, and a flow controller. A mixing control process is:

[0036] 1) The water volume identifier before mixing is calculated by the water content identification formula based on the ore output Mo, the actual water addition Wact and the water content pe after primary mixing, and the calculated results are compared with the water content before mixing calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com