Shifting device for transmission

A shifting device, transmission technology, applied in the direction of transmission control, elements with teeth, belts/chains/gears, etc., can solve problems such as smaller or additional settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

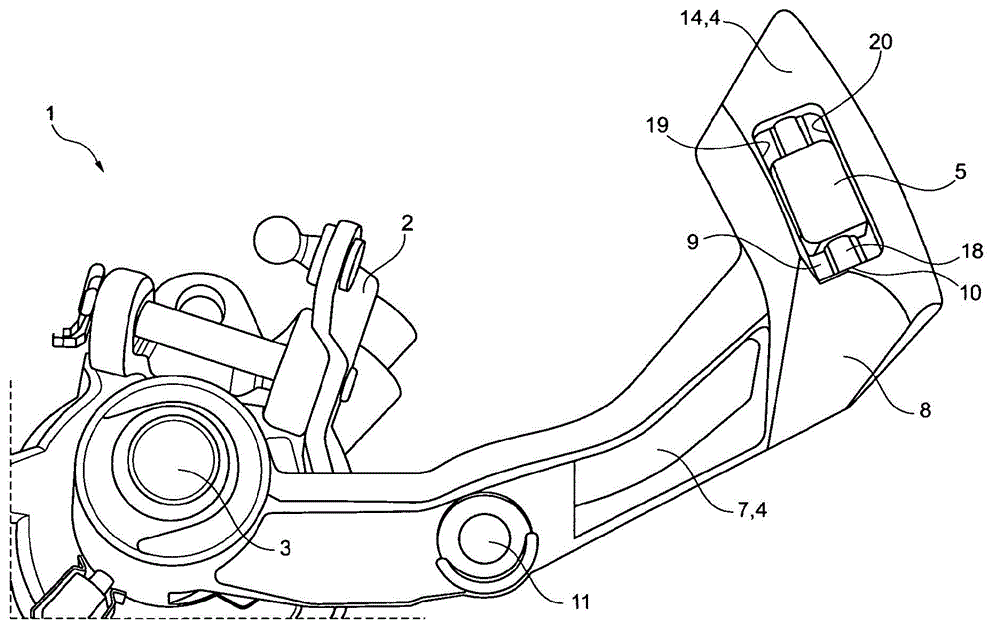

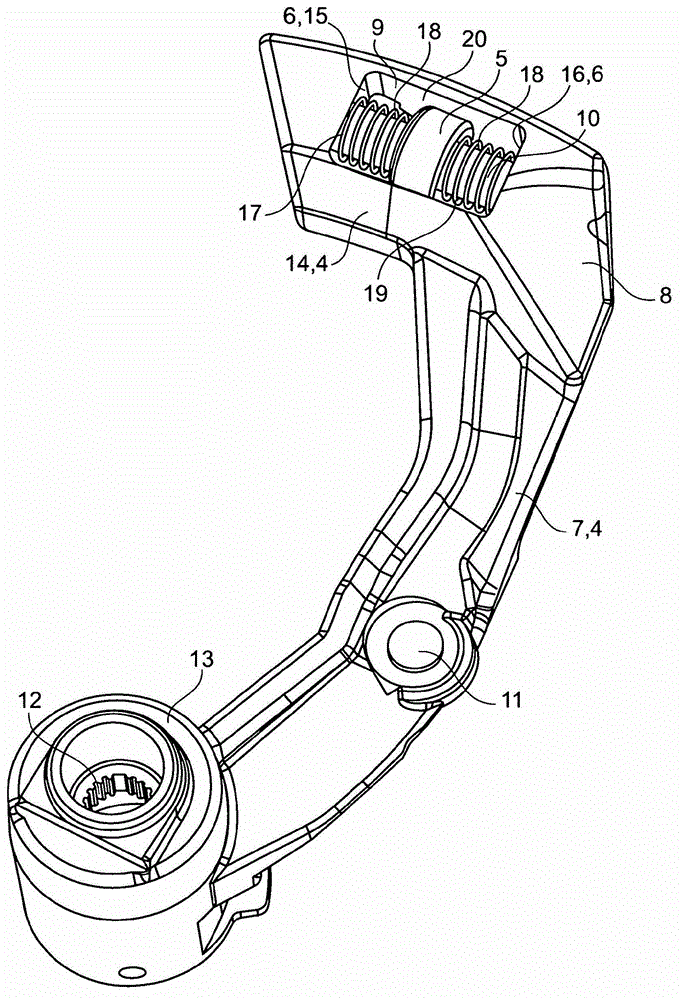

[0027] figure 1 A part of a shifting device 1 for an automotive gear transmission is shown. The manual selector lever, not shown, acts on the additional mass 4 via a suitable linkage or shift fork via the ball joint 11 . As a result, the selector shaft 3 is twisted, which engages or disengages a selector gear of the transmission by means of a selector lever finger (not shown). The selector shaft 3 can be moved axially with the selector lever 2 without the additional mass being axially moved together.

[0028] The cylinder 13 is mounted on the shift shaft 3 in a rotationally fixed manner by means of the internal toothing 12 . The cylinder 13 has a substantially radially oriented overhang 7 which transitions at its radially outer end 8 into a tangentially oriented curved end piece 14 . The end piece 14 and the boom 7 are formed in one piece and together form the additional mass 4 . Due to the rotationally fixed connection to the selector shaft 3 , the rotational or pivoting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com