Capillary pressure regulator with stable pressure-regulating performance

A capillary pressure regulator technology, applied in the field of pressure regulators, can solve the problems of inconspicuous adjustment of outlet pressure, inapplicability of capillary level flow, unstable outlet pressure, etc., to increase the use range, facilitate installation and replacement, and export The effect of pressure stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

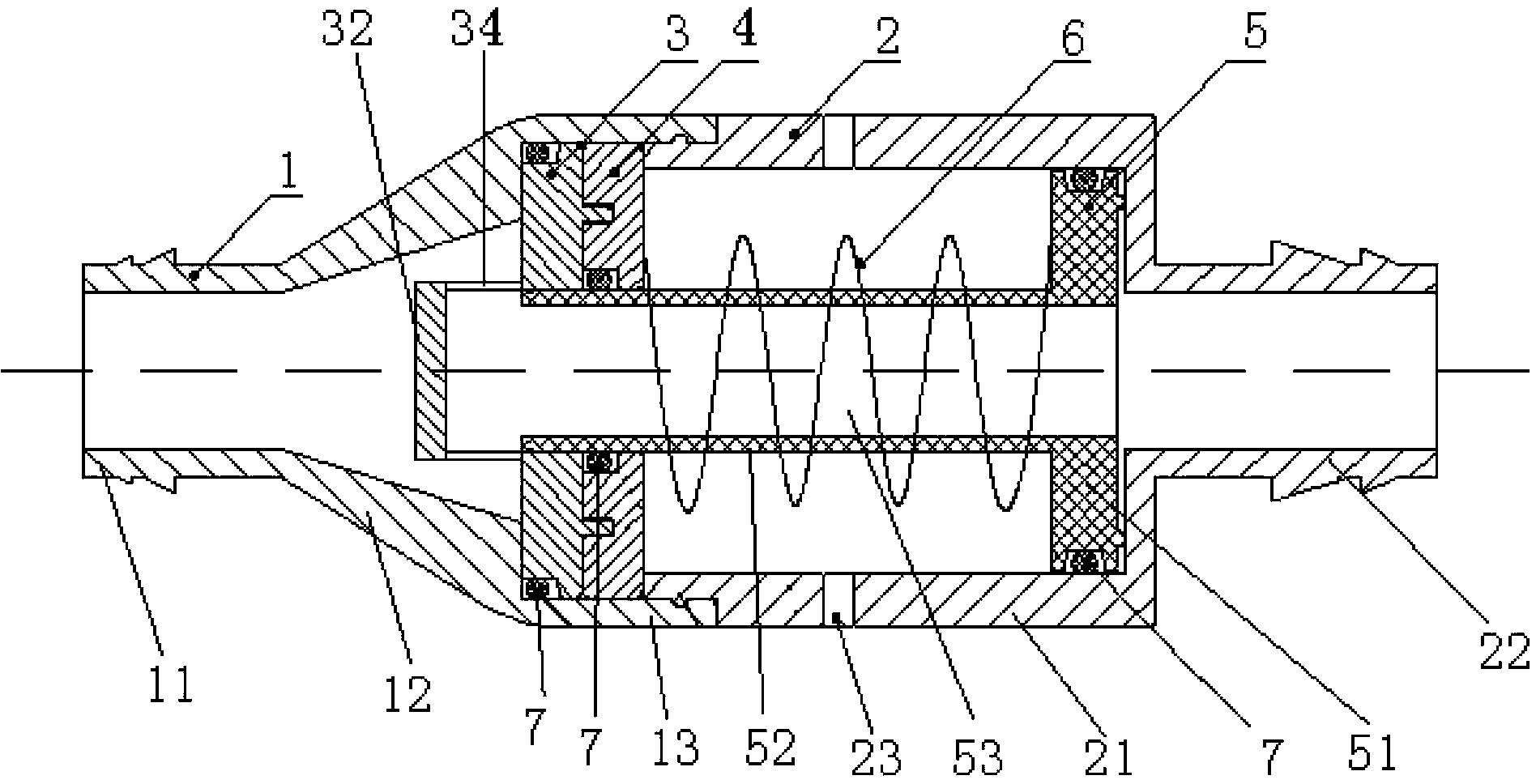

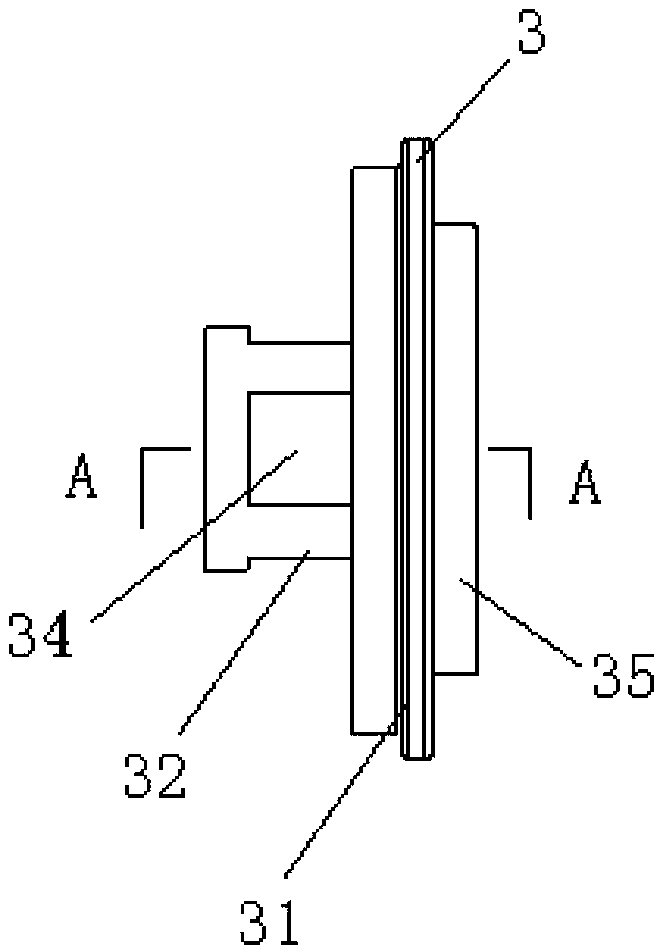

[0021] Such as figure 1 As shown, the present invention includes an upstream housing 1 , a downstream housing 2 , a guide body 3 , a pin support 4 , a T-shaped pressure regulating assembly 5 and a pressure regulating spring 6 .

[0022] Such as figure 1As shown, the upstream casing 1 of the present invention includes a first cylindrical section 11, a conical diffuser section 12 and a second cylindrical section 13 that are integrally arranged in sequence, and the central axis of the first cylindrical section 11 is the same as the central axis of the conical diffuser section 12 and the second cylindrical section. The central axes of the cylinder segments 13 coincide. The outer diameter of the first cylindrical section 11 is smaller than that of the second cylindrical section 13 , and the outer diameter of the conical diffuser section 12 gradually increases from the connection with the first cylindrical section 11 to the connection with the second cylindrical section 13 . The...

Embodiment 2

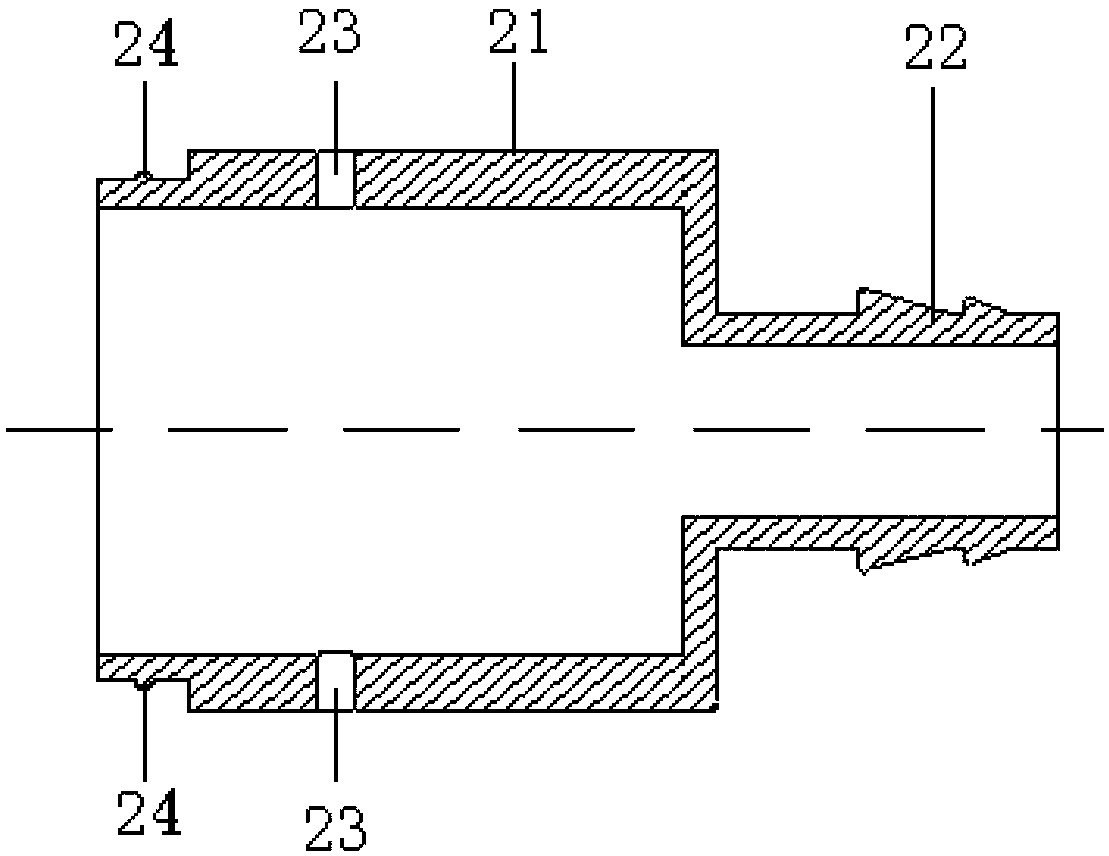

[0033] Such as Figure 7 As shown, the difference between the second embodiment and the first embodiment is that the downstream casing 2 of the present invention includes a third cylindrical section 21 and a fourth cylindrical section 22 integrally arranged, and the central axis of the third cylindrical section 21 is connected to the fourth cylindrical section. The central axis of the section 22 is vertical; that is, the side wall of the fourth cylindrical section 22 is provided with a through hole communicating with the inside of the third cylindrical section 21, and the diameter of the second circular body 51 of the T-shaped pressure regulating assembly 5 is larger than that of the fourth cylindrical section 22. The diameter of the through hole provided on the side wall of the cylindrical section 22 . Both ends of the fourth cylindrical section 22 are water outlets, and the end of the first cylindrical section 11 of the upstream casing 1 is a water inlet. The structure and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com