Friction stir welding member

A technology of friction stirring and joining parts, which is applied to welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve the problems of increased man-hours, etc., to prevent corrosion, reduce man-hours, and reduce operating man-hours Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

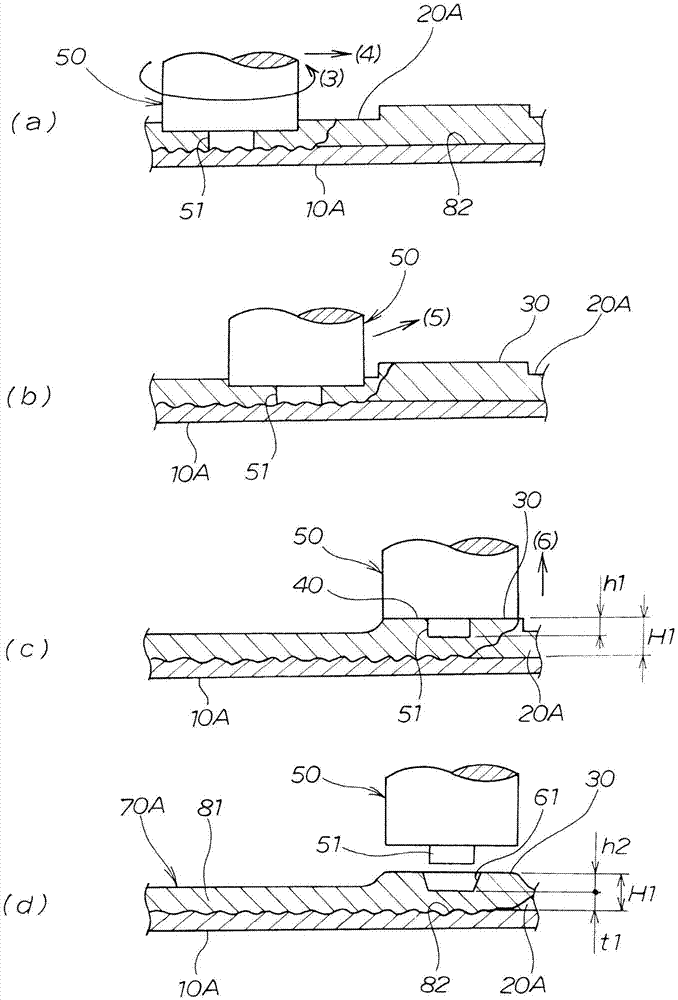

[0039] Embodiments of the present invention will be described with reference to the drawings.

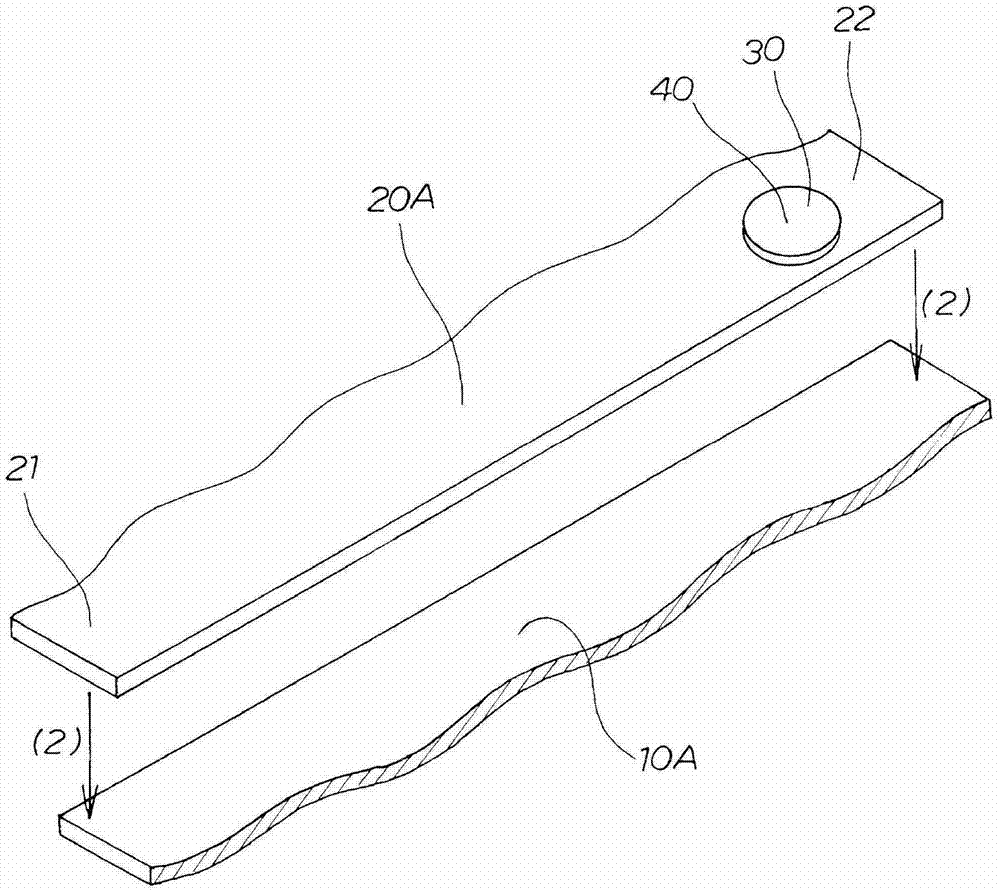

[0040] Such as figure 1 As shown, the second member 20A is stacked on the first member 10A arranged on the lower side as indicated by the arrow ( 2 ), and the second member 20A is positioned relative to the first member 10A. The second member 20A is a member having a material different from that of the first member 10A. Next, pass figure 2 The cross-sectional structures of the first member 10A and the second member 20A will be described.

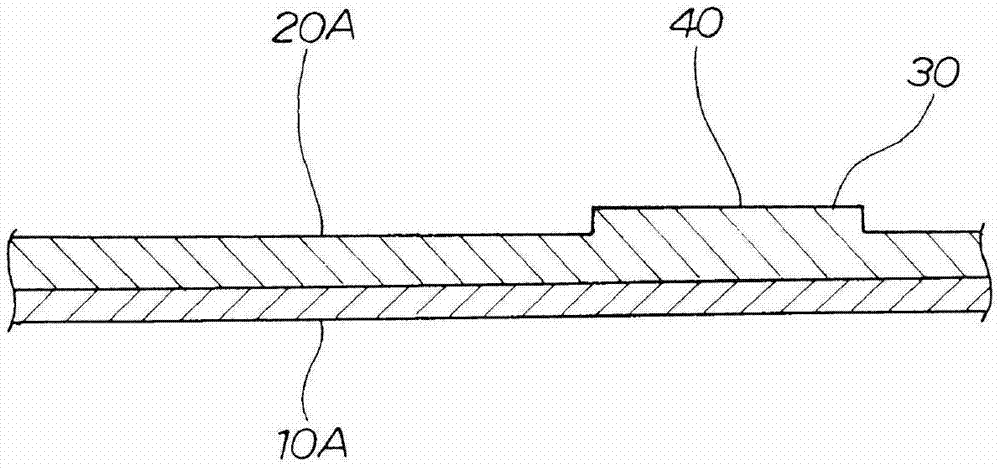

[0041] Such as figure 2 As shown, the second member 20A is integrally provided with a columnar second protrusion 30 protruding toward the bonding tool (described later) side. The second protrusion 30 is formed to be higher than the length (described later) of a pin (described later) of the bonding tool.

[0042] In addition, a joining end portion 40 (details will be described later) is provided on the second convex portion 30 . from one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com