Anti-backward-slip device of wind driven generator and use method

A technology for wind turbines and generators, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low work efficiency, high labor intensity, and unfavorable mass production, so as to improve labor efficiency and work efficiency. , the effect of shortening the labor time of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings and embodiments.

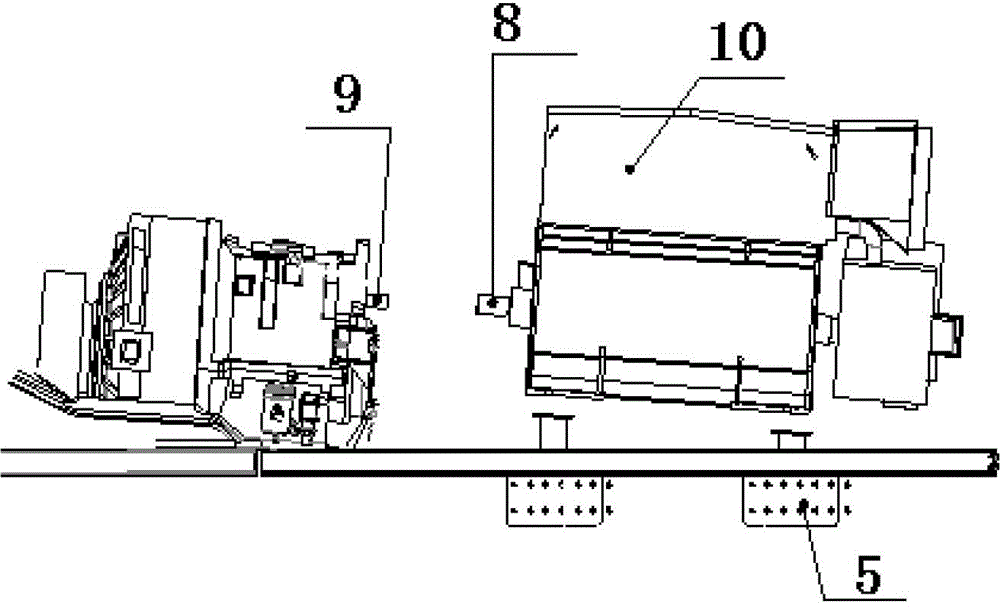

[0028] Such as figure 1 As shown, the partial structure diagram of the generator set includes a generator input shaft 8, a gearbox output shaft 9, a generator 10, and a generator underframe beam 5.

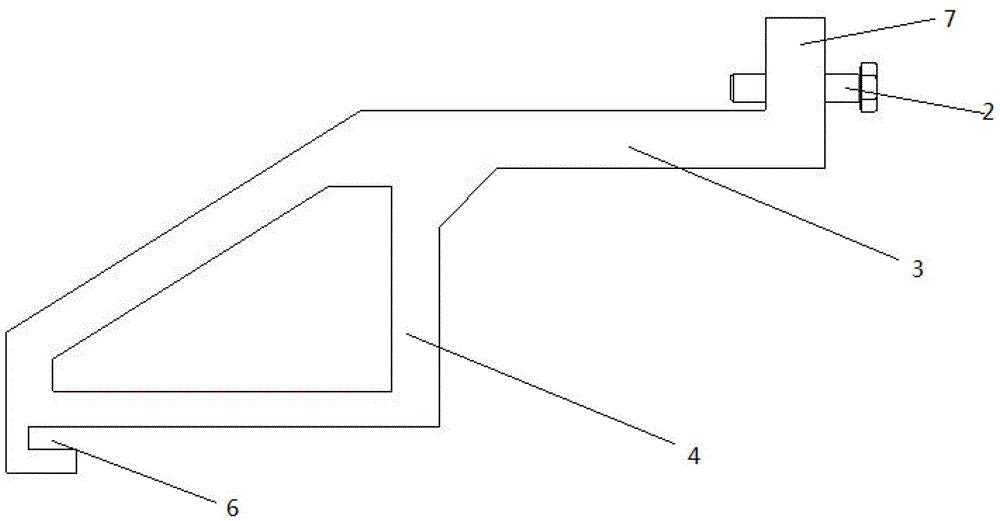

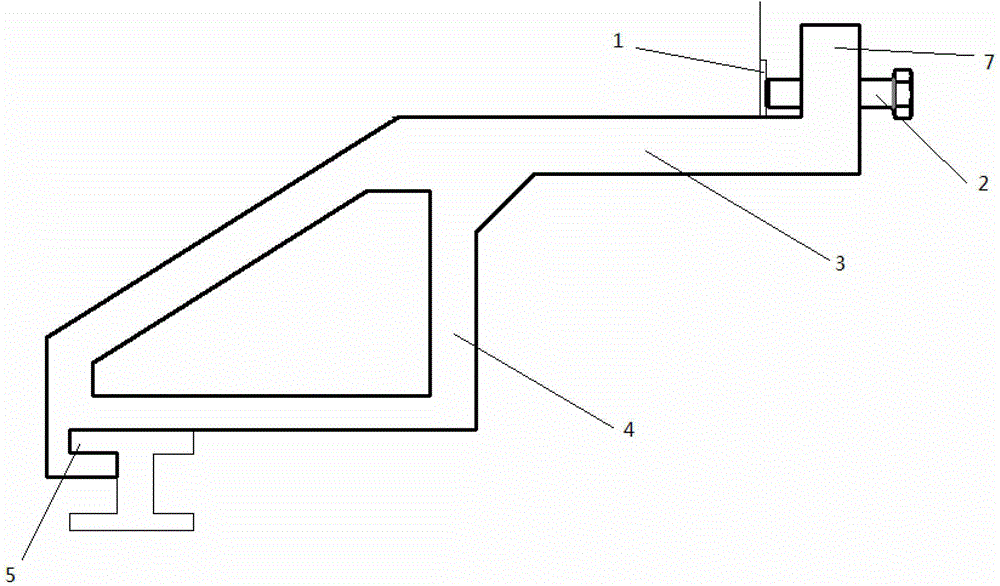

[0029] Such as figure 2 As shown, a wind turbine anti-skid device includes a right-angled triangular frame 4, a lateral groove 6 is provided on the outer side of an acute angle of the triangular frame 4, and an end belt is provided on the outer side of the other acute angle of the triangular frame 4 A horizontal plate 3 with a baffle I7.

[0030] The baffle plate I7 is provided with a threaded hole, and an M24 bolt 2 is inserted into the threaded hole, and a baffle plate II1 is provided at the position where the M24 bolt 2 contacts the generator.

[0031] The size of the transverse groove 6 is matched with the size of the generator underframe beam 5, and the transverse groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com