Multifunctional machine

A multi-function machine and output shaft technology, which is applied to portable mobile devices, manufacturing tools, etc., can solve problems such as inability to install output shafts, type restrictions, etc., and achieve the effect of improving versatility and convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

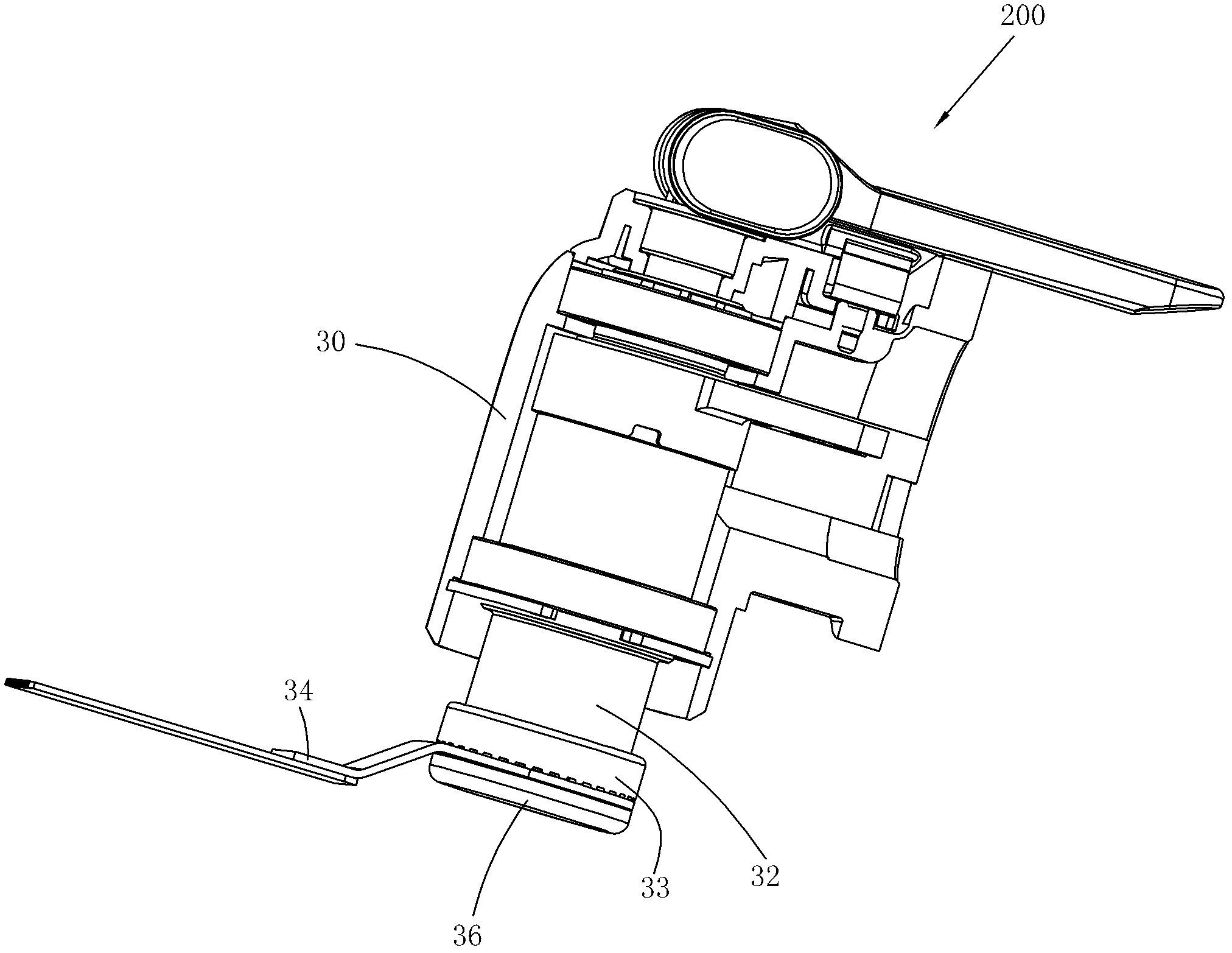

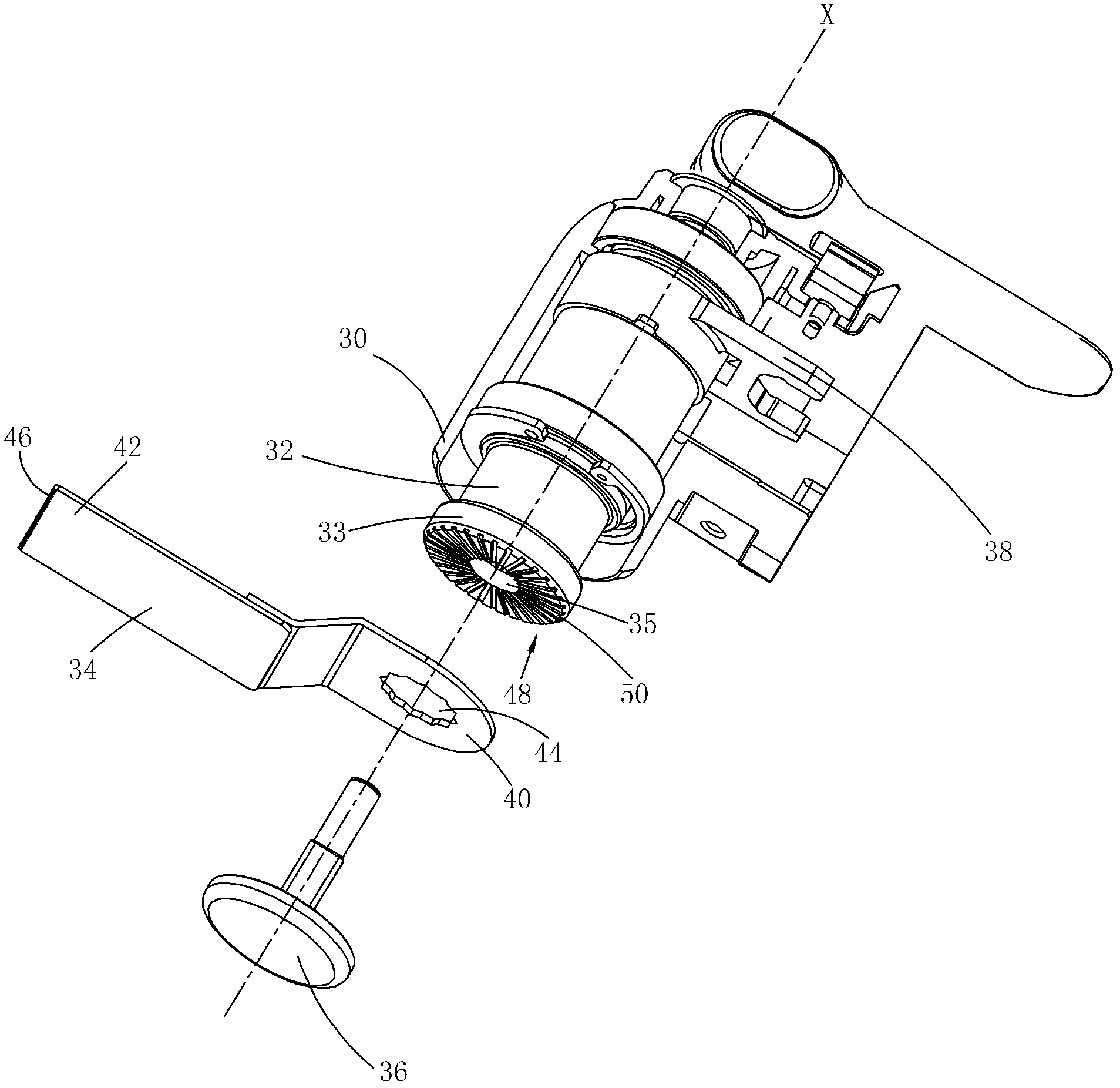

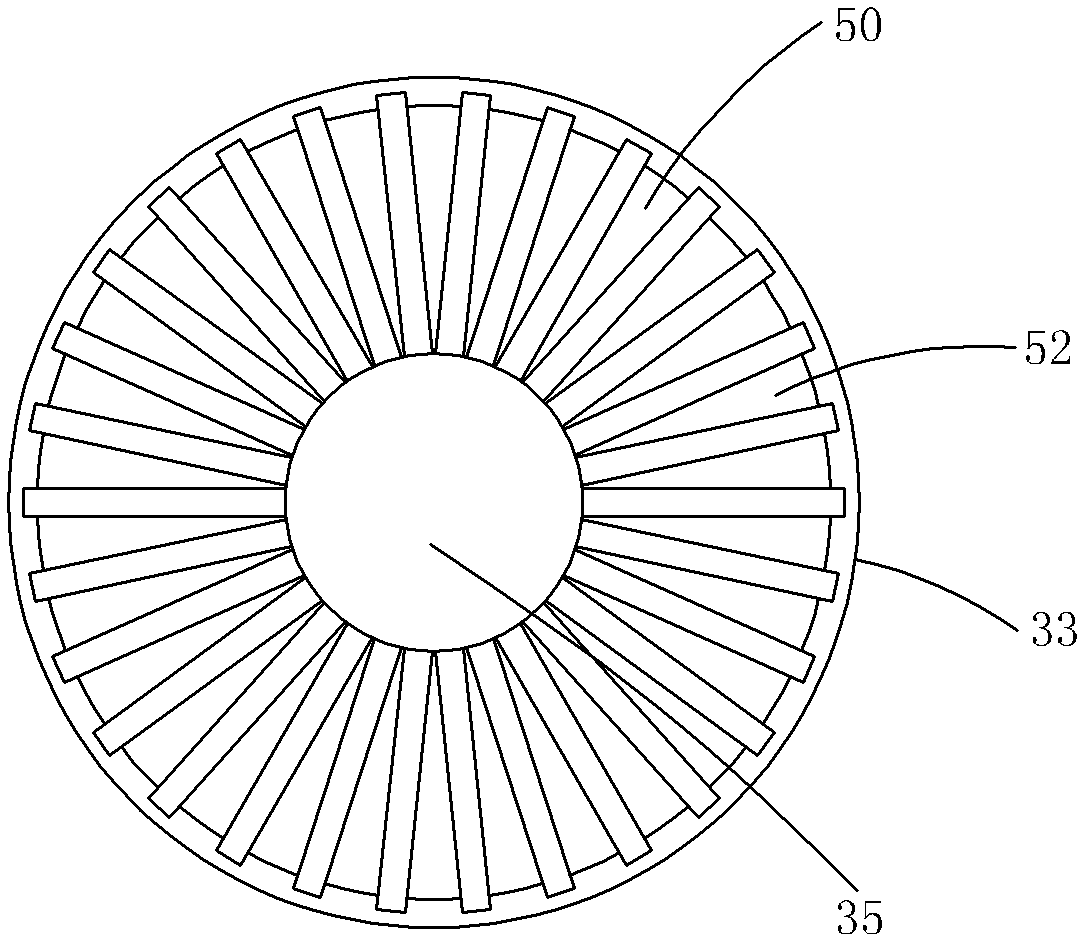

[0069] figure 1 Shown is the head area of the multifunction machine 200 in the first embodiment of the present invention. The multifunctional machine 200 includes a casing 30 , a motor (not shown) installed in the casing 30 , an output shaft 32 driven by the motor, and a working head 34 installed below the output shaft 32 . A fastener 36 passes through the working head 34 and is connected to the end of the output shaft 32 , so that the working head 34 is fixed on the output shaft 32 and can move under the drive of the output shaft 32 .

[0070] see figure 1 and figure 2 As shown, the output shaft 32 is disposed longitudinally inside the housing 30 , and its end extends out of the housing 32 for a certain distance. A shift fork 38 is installed on the output shaft 32. When the motor rotates, it can drive an eccentric device (not shown) to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com