Ink barrel and ink barrel cover

A technology of ink barrel and barrel mouth, which is applied in the field of printing, can solve the problems such as difficult replacement of ink, achieve the effect of improving work efficiency and overcoming difficult replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments. The ink tank herein includes an ink tank for containing printing ink, and a waste ink tank for containing waste ink.

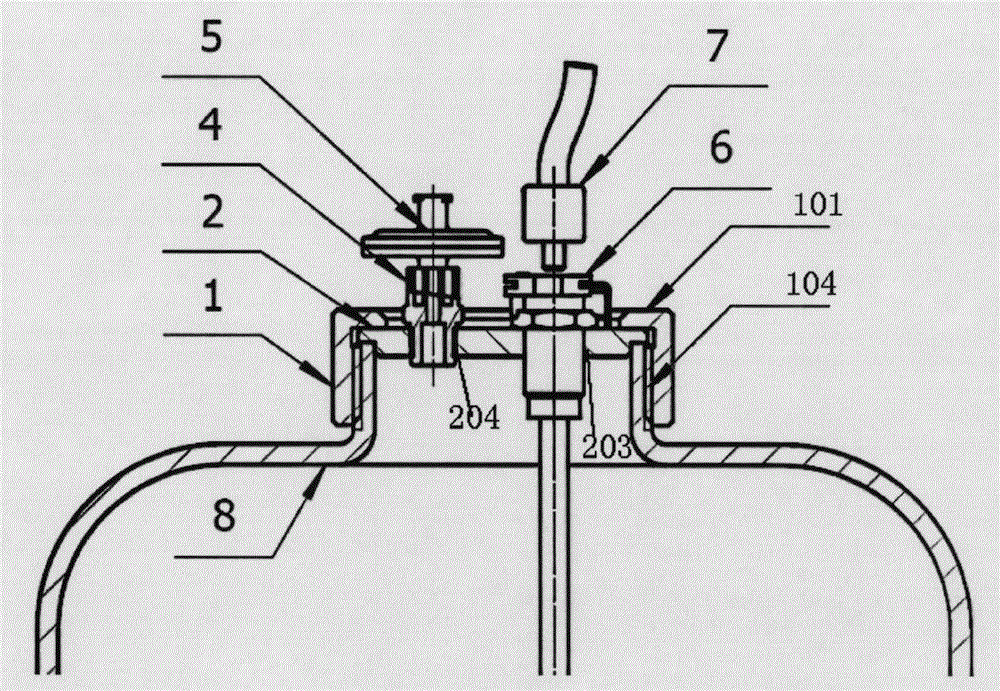

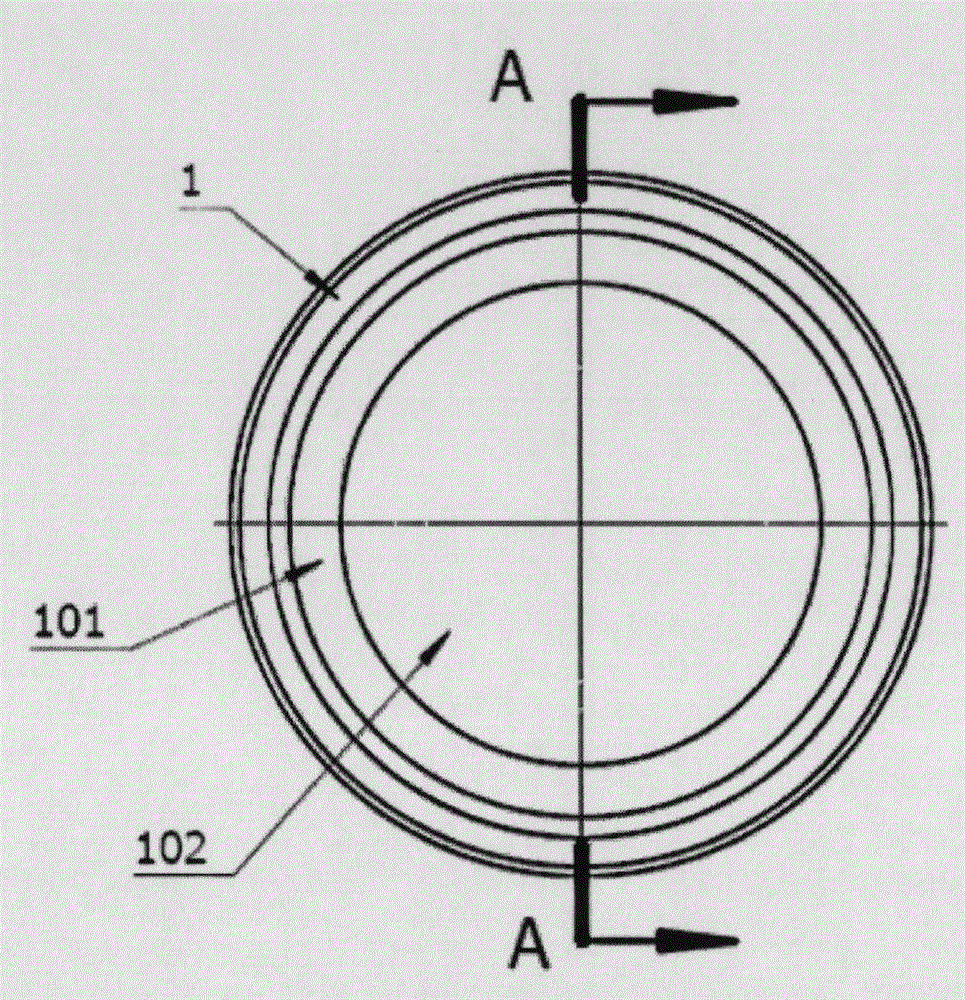

[0016] figure 2 Shows a partial cross-sectional view of an ink barrel (that is, an ink barrel for containing printing ink) according to an embodiment of the present invention, including a barrel body 8 and a cover, and the cover includes: a tray 2 with perforations 203, 204, the area of the tray 2 Capable of covering the barrel mouth of the barrel body 8; the gland 1, the tray 2 can be embedded in the gland 1, and the gland 1 includes: an assembly part 104 for detachably installed on the barrel mouth; The ends are extended and formed, and the crimp 101 is ring-shaped, which can expose the perforations 203 , 204 of the tray 2 and can cover the periphery of the tray 2 .

[0017] figure 2 Among them, 4 is a filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com