Spinning trolley

A cart and wheel technology, applied in the field of textile carts, can solve the problems of time-consuming, small cart transportation, low efficiency, etc., and achieve the effects of avoiding multiple transfers, high degree of automation, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment

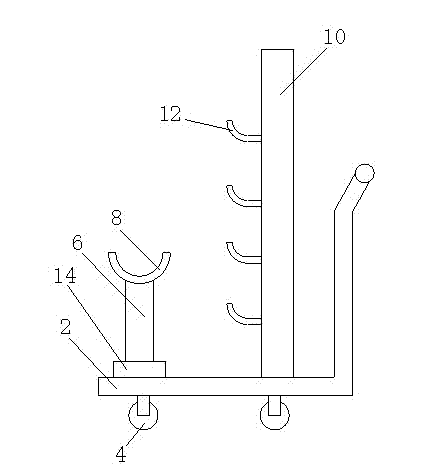

[0011] see figure 1 As shown, a textile cart includes a bottom frame 2 and wheels 4 installed at the bottom of the bottom frame 2. A telescopic support arm 6 is vertically arranged on the bottom frame 2. The top end of the support arm 6 is provided with a Bracket 8, the support arm 6 can move horizontally along the bottom frame 2, and the bottom frame 2 is also provided with a rectangular stand 10, and the two vertical frames of the rectangular stand 10 are evenly spaced There are a plurality of arc-shaped support rods 12, wherein the bottom of the support arm 6 is in contact with the surface of the bottom frame 2 through the slider 14, and the surface of the bottom frame 2 is provided with a track (not shown) that matches the slider 14 ), when in use, the take-up rollers are respectively placed on the support rods 12 of the stand 10 throug...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap