Subway platform screen door panel lock

A technology for subways and facades, applied in building locks, buildings, building structures, etc., can solve problems such as affecting operation, easy upturning of the panel 100, and inability to lock smoothly, meeting the requirements of cleanliness, and not easily deformed and upturned. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The subway screen door panel lock according to the embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

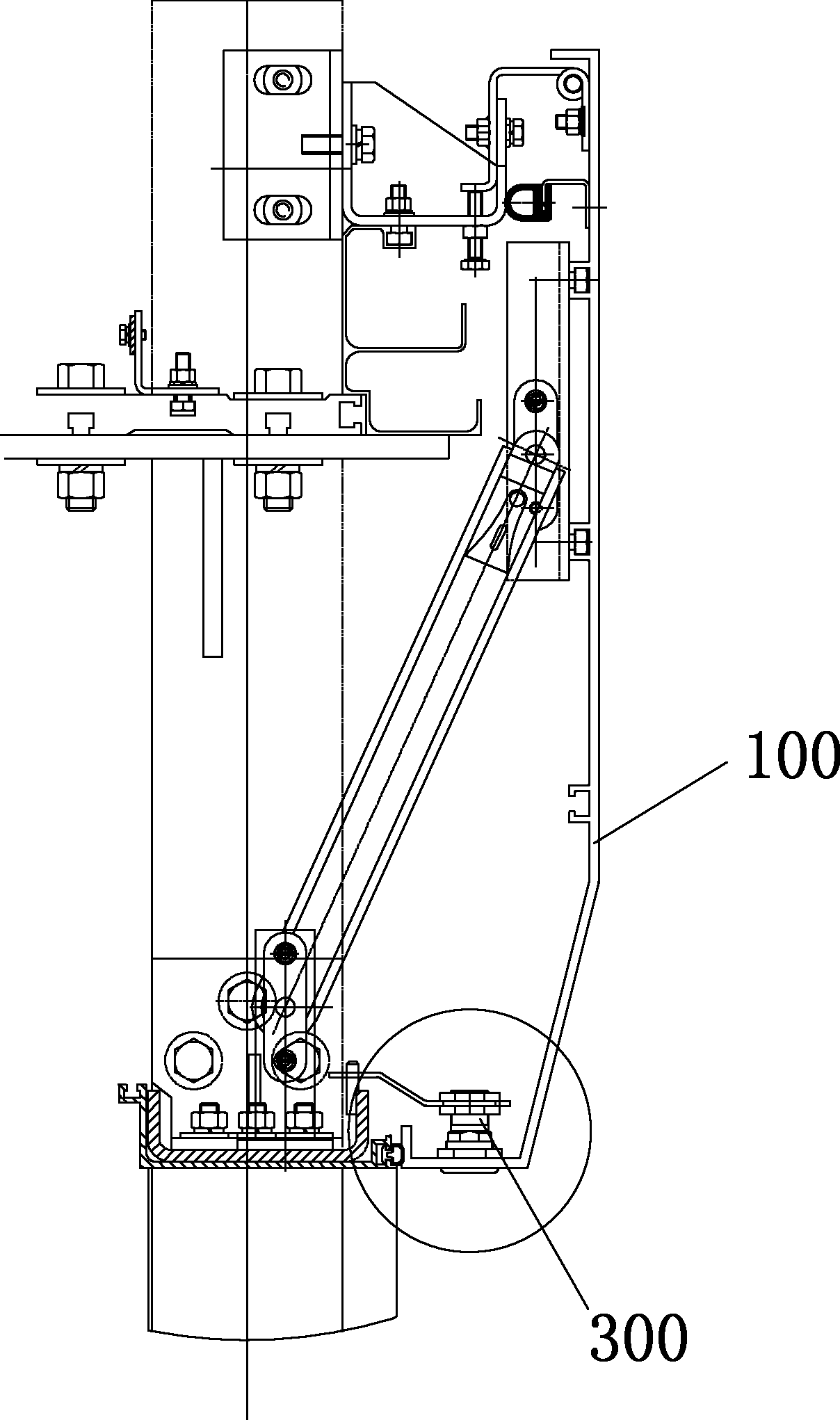

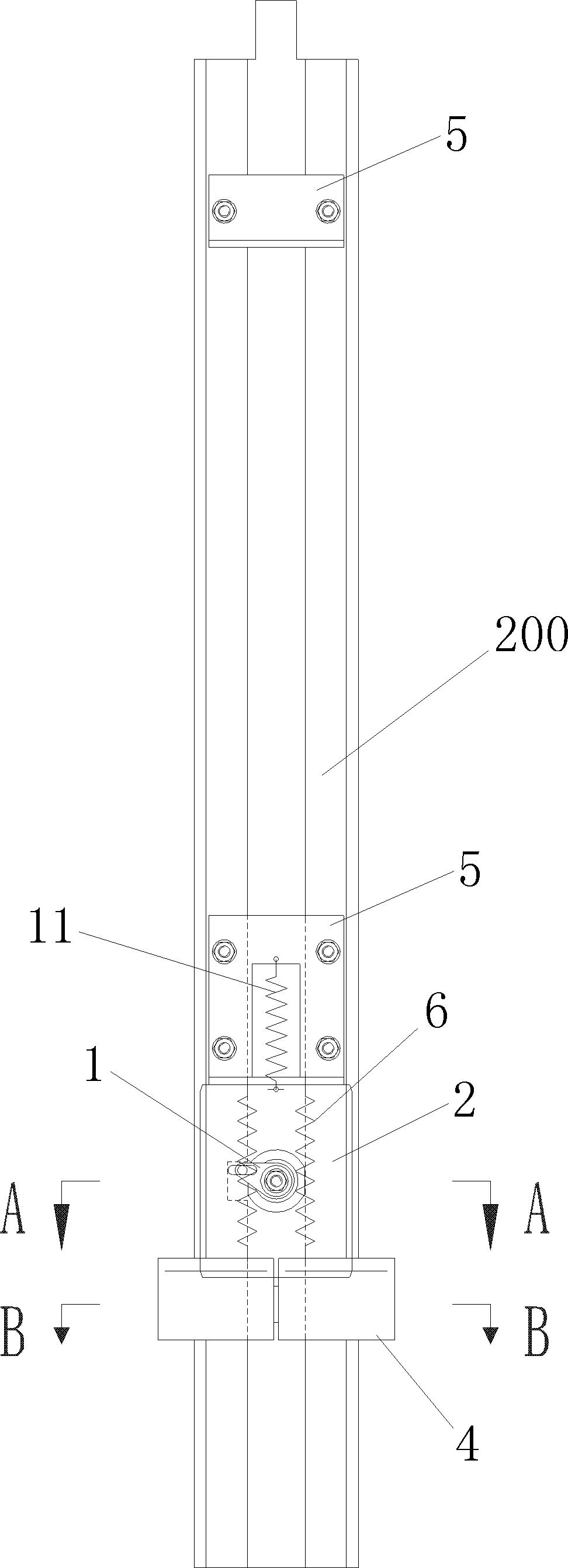

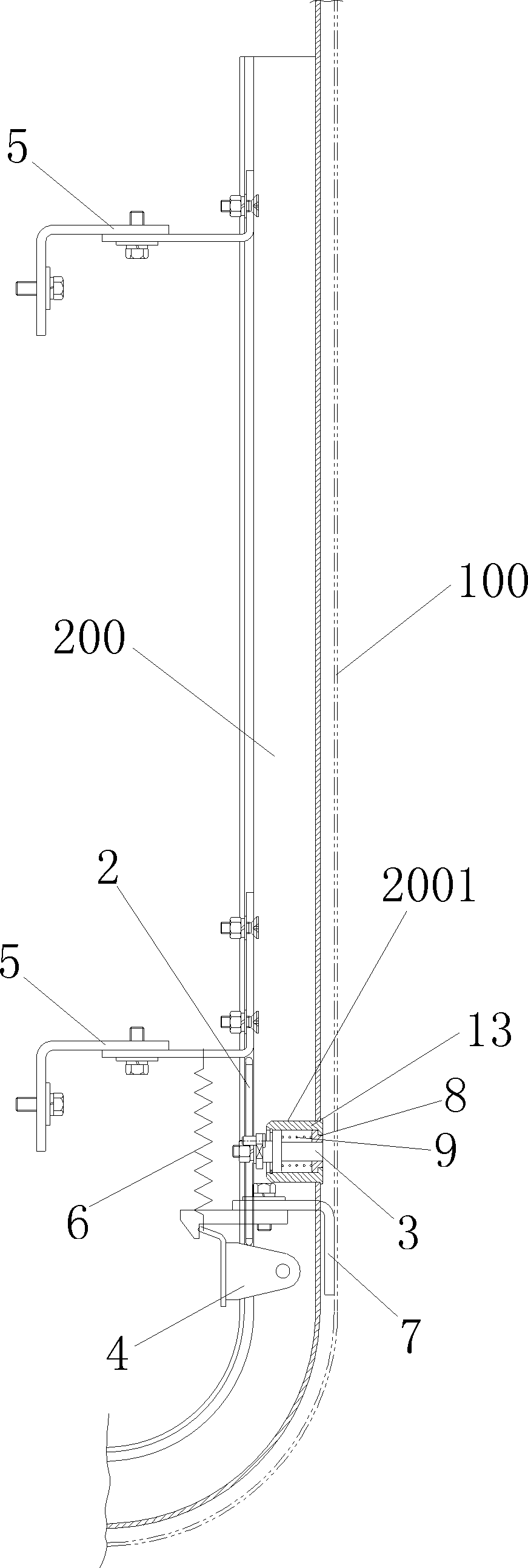

[0039] figure 2 In order to show the front structure diagram of the subway screen door panel lock installed on the total support and the panel of the embodiment of the present invention, image 3 For showing the embodiment of the present invention, the panel lock of the subway screen door is installed on the side sectional structural schematic diagram of the total support and the panel, Figure 4 It is a schematic diagram of the cooperation structure of the lock cylinder assembly and the slide plate of the subway screen door panel lock according to the embodiment of the present invention, Figure 5 In order to show the schematic diagram of the interlocking structure of the locking mechanism and the locking mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com