Front-in front-out ink-jet printing equipment

An inkjet printing equipment, forward-forward-out technology, applied in printing devices, printing and other directions, can solve the problems of the limitation of printing medium softness, shorten the service life of printers, and wear parts, etc., and achieve long service life, low cost, and low cost. The effect of softness requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

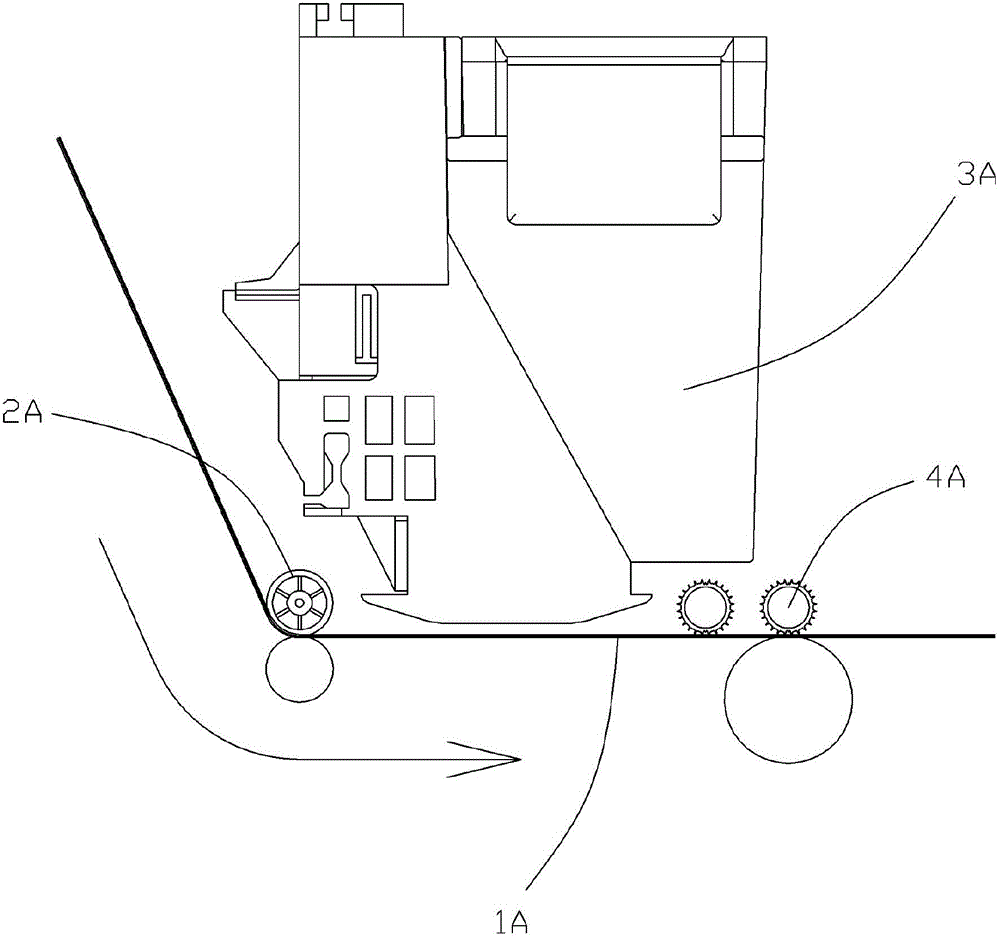

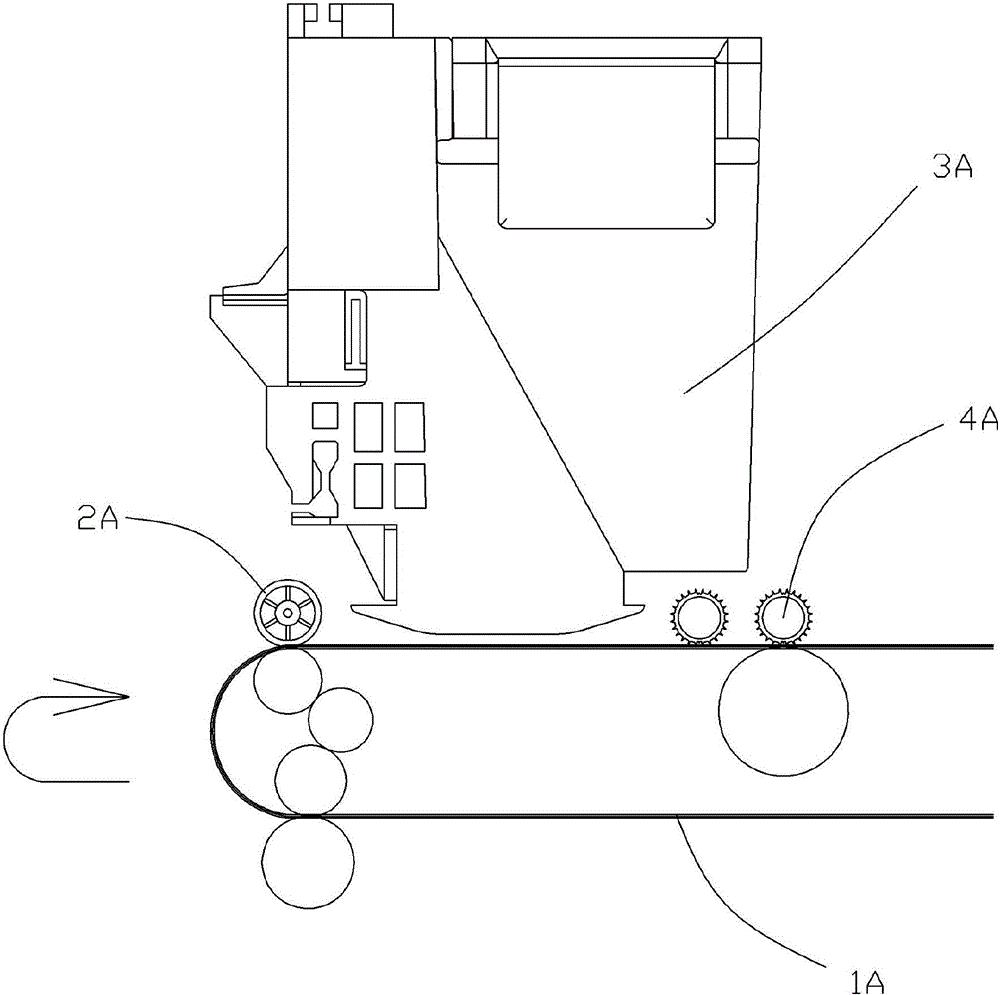

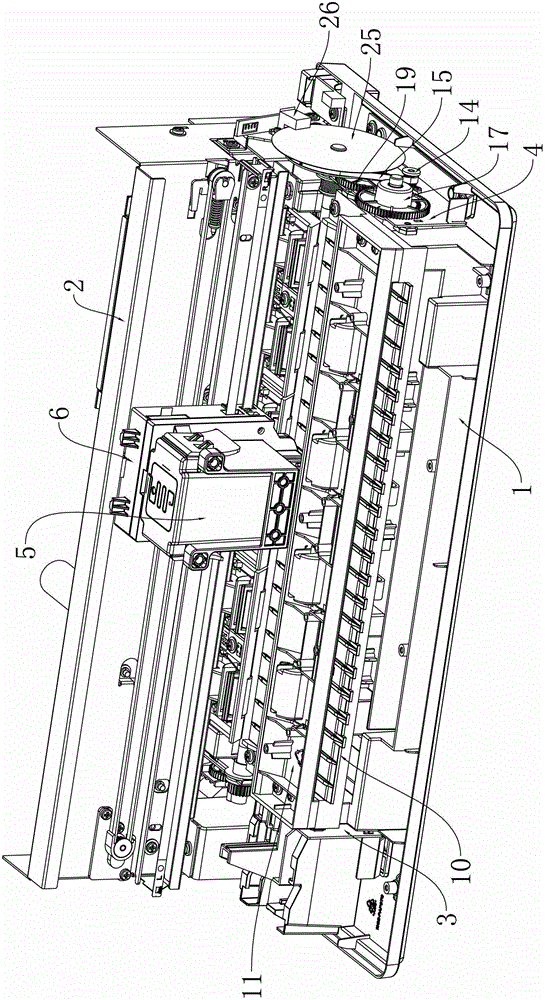

[0030] see image 3 , Figure 3A and Figure 4 , an inkjet printing device of the present invention includes a frame composed of a bottom shell 1, a rear wall panel 2, a left wall panel 3, a right wall panel 4, and an upper shell. For clarity, the upper shell and other parts have been changed from Hidden in the picture. A power supply board 30 and a main board 31 are provided on the back side of the rear wall board 2, and a main control chip is provided on the main board 31 to control the operation of the entire inkjet printing equipment. Such as image 3 and Figure 4 As shown, the rear wall panel 2 , the left wall panel 3 and the right wall panel 4 are vertically arranged on the rear side, the left side and the right side of the bottom case 1 respectively. The rear wall panel 2 is provided with a movable inkjet unit, the inkjet unit includes an ink cartridge 5 and a carriage 6, wherein the carriage 6 is installed on the slide rail 7 of the rear wallboard 2, and the carr...

Embodiment 2

[0043] Such as Figure 8 As shown, the structure of the inkjet printing device of this embodiment is basically the same as that of Embodiment 1, the only difference is that there is only one sensor 29 connected to the main control chip on the axial side of the first paper guide roller 20 . The sensor 29 can simultaneously detect the presence or absence of the printing medium and the front / end position of the printing medium. Compared with Embodiment 1, this embodiment can achieve the purpose of cost saving.

[0044] This embodiment also has two working modes:

[0045] 1. Method 1: print while unloading the paper

[0046] The printing medium is put in from the paper inlet 13 and pushed onto the first paper guide roller 20 → the sensor 29 detects the existence of the printing medium and sends out a signal → the main control chip receives the signal and sends out an instruction, and the paper feeding motor 14 drives the first A paper guide roller 20 and the first friction whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com