Sliding element of guide device of adjustable roof element of openable roof

A technology for sliding elements, guides, applied in the direction of roofs, vehicle components, transport and packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

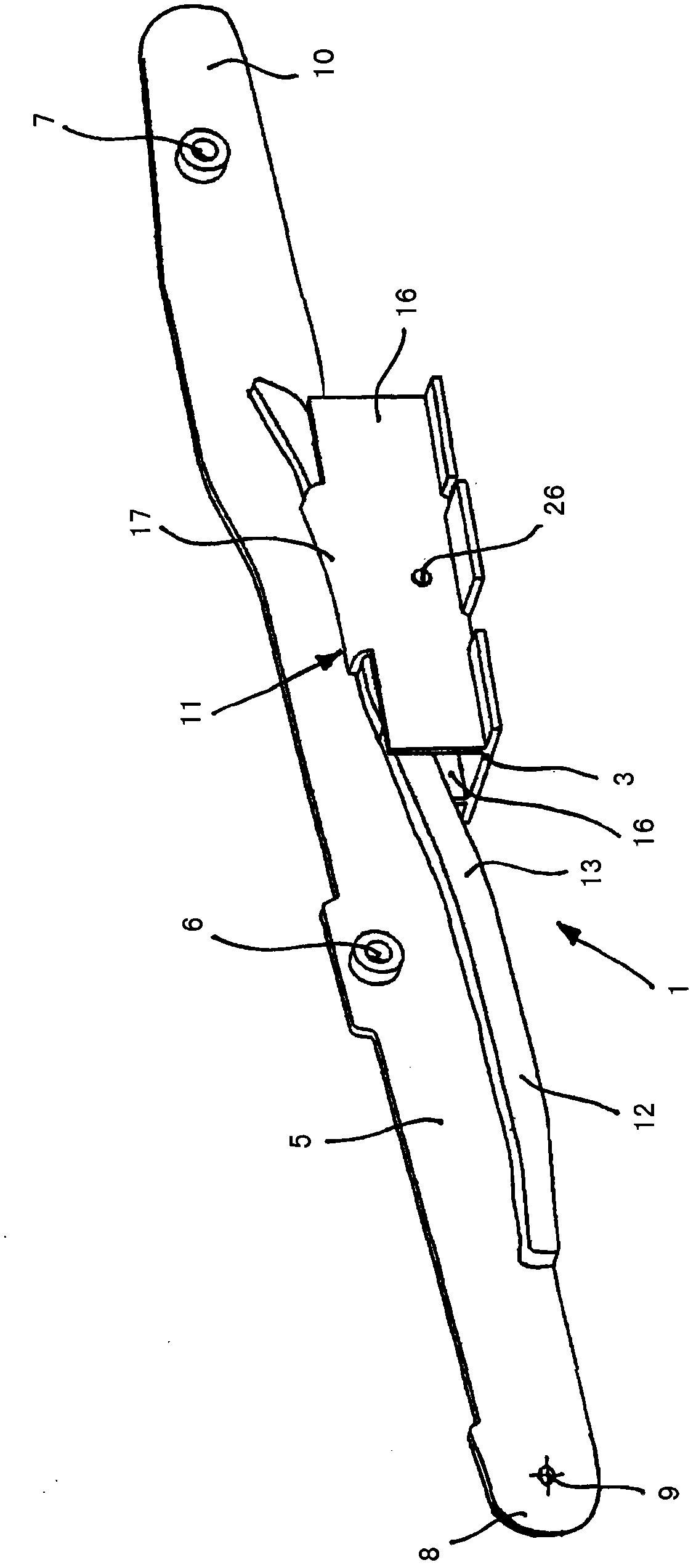

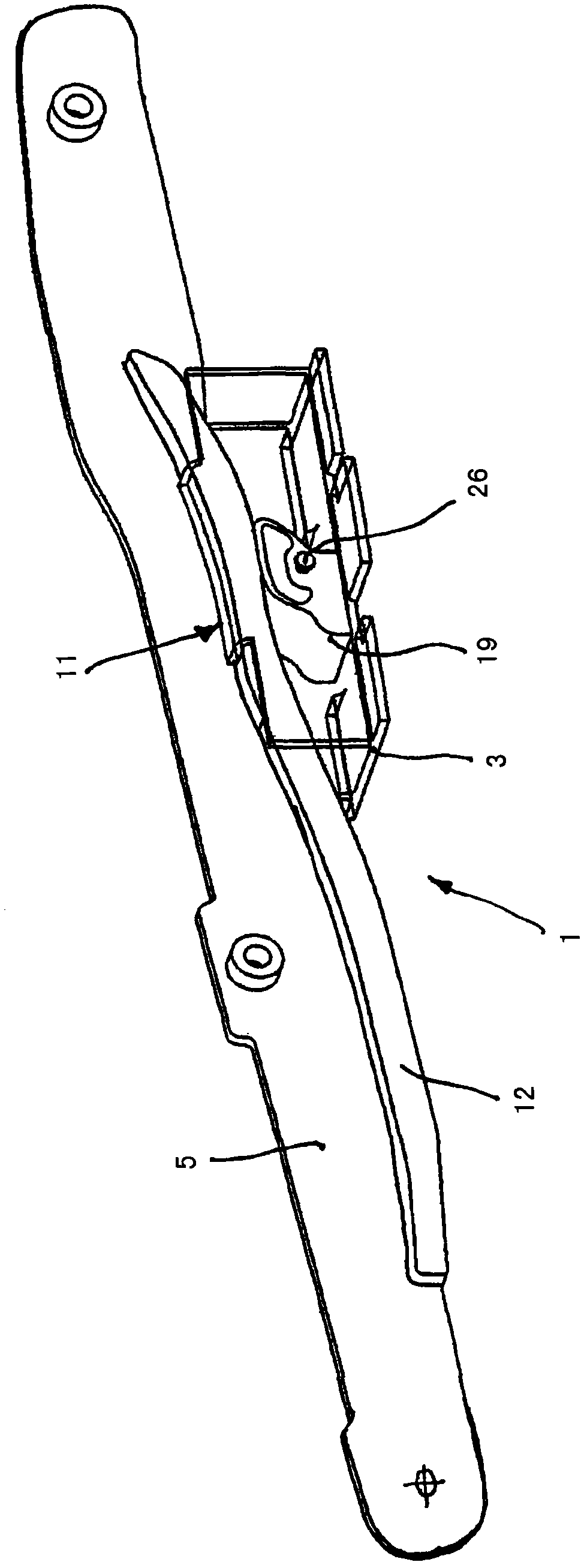

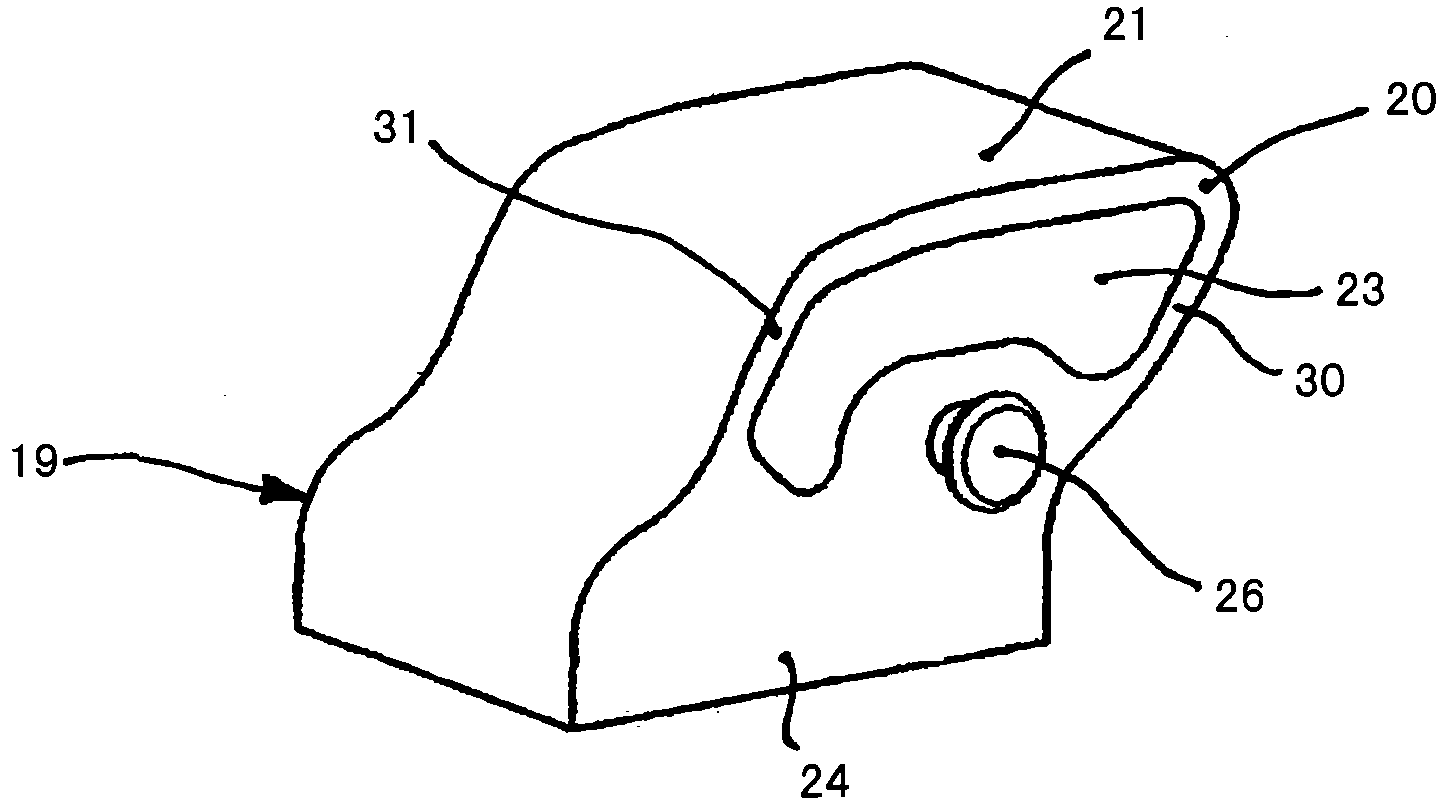

[0028] A movable roof element such as a roof 2 for an openable motor vehicle roof (or vehicle roof) (see Figure 5 ) The adjusting device 1 for stroke adjustment has a slide 3 which is movably received on a roof-side guide rail or guard rail 4 along a roof carrier 5 and is adjusted, for example, by means of a pressure-resistant drive cable. . The openable motor vehicle roof is, for example, a sliding roof, a slide-push roof or a spoiler roof, the roof 2 of which can be adjusted in a known manner between a closed position and an open position in order to release the The roof opening of the roof of a motor vehicle. The roof 2 mounted on the roof carrier 5 at the fastening points 6 and 7 shown by way of example can be swiveled into a swivel or ventilation position with the rear edge raised, in that the roof carrier 5 pivots up with its rear edge about a pivot axis 9 arranged on its front end 8 .

[0029] The sliding seat 3 includes a guide unit 11 which cooperates with a slidin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com