Automatic container loading and unloading equipment with fixing spin locks

An automatic loading and unloading, container technology, applied in the directions of loading/unloading, transportation and packaging, can solve the problems of casualties, large occupation, affecting the health of on-site workers, etc., to improve the level of safety management and ensure personal safety. Safety and the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

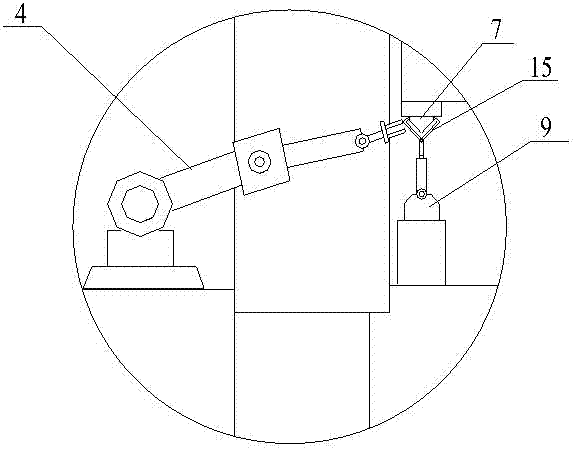

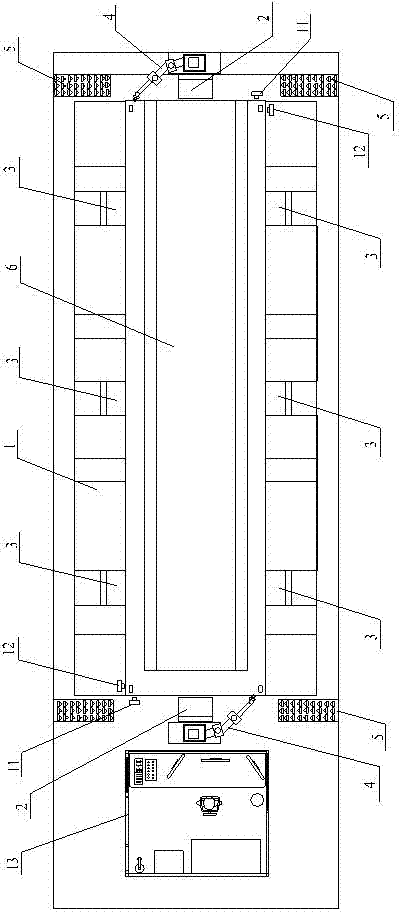

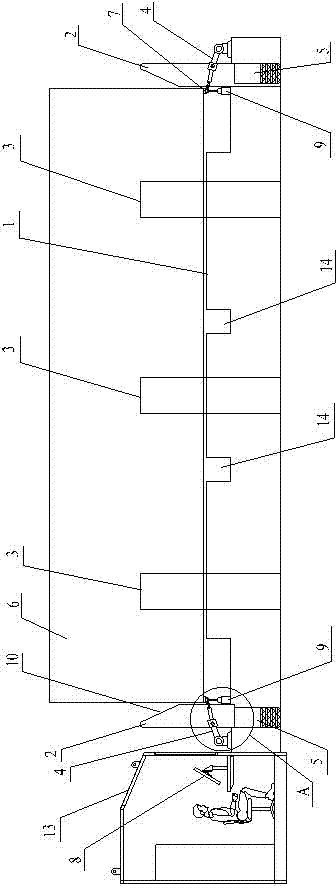

[0023] The container fixed twist lock automatic loading and unloading equipment of this embodiment is mainly composed of container parking platform 1, limit stoppers 2, 3, intelligent manipulator 4 and control device 8, etc., see figure 1 , image 3 shown. Wherein, the container parking platform 1 is used to carry the container 6, and forms a boss with a high middle and low left and right sides, the raised part in the middle is used to support the bottom surface of the container 6, and the low parts at the left and right sides can make the rotation at the four corners of the bottom surface of the container 6. The lock 7 or the keyhole for installing the twist lock 7 is exposed, so that the intelligent manipulator 4 can disassemble and assemble the lock. The stoppers 2 and 3 are used to limit the parking position of the container 6 on the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com