Steel floor

A steel and floor technology, applied in the direction of floors, buildings, building structures, etc., can solve the problems that hollow steel plates cannot withstand the heavy pressure of large equipment, and solid steel plates have defective anti-static effects, and achieve convenient installation and simple principles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

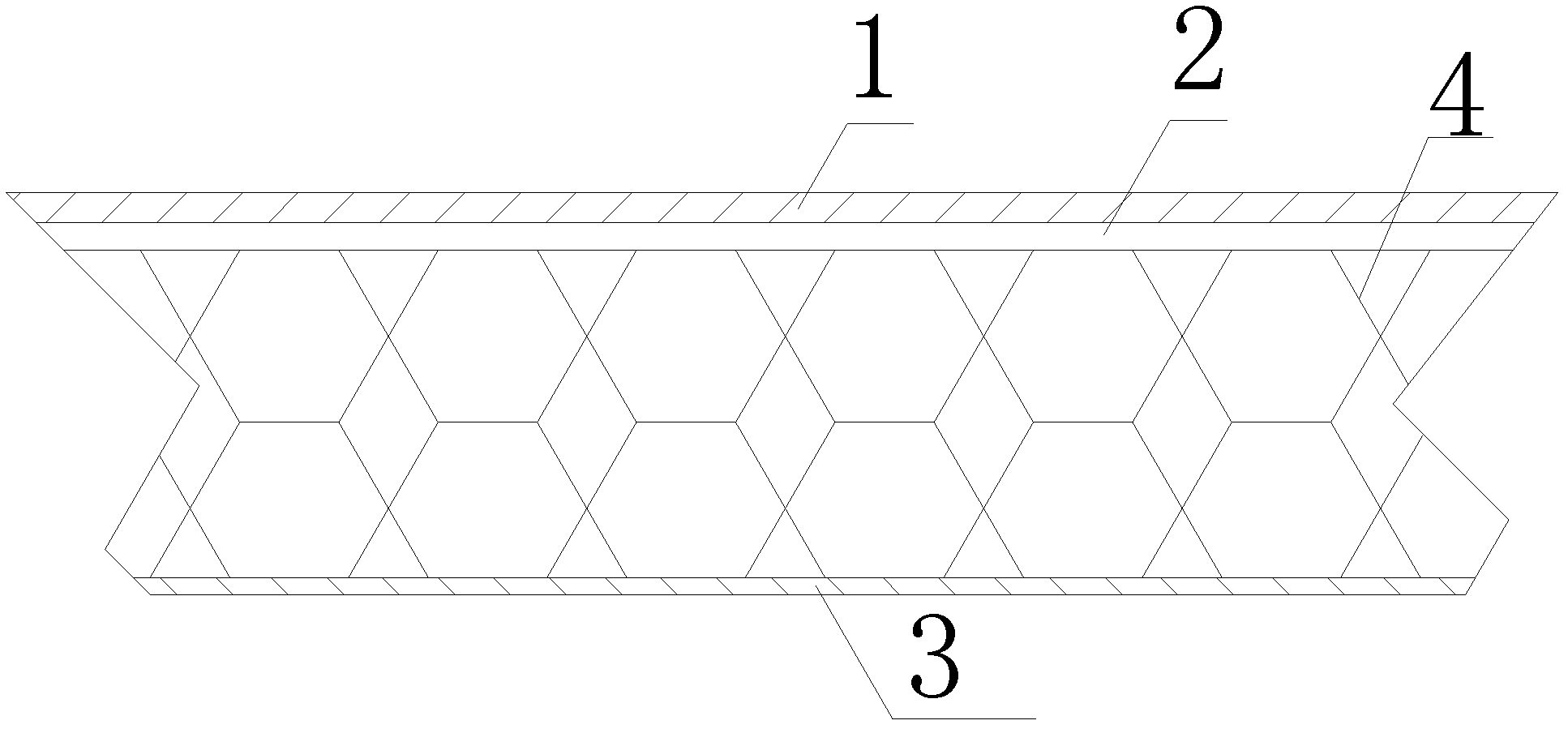

[0010] As shown in the figure, the present invention is a steel floor with an antistatic layer 2 on a steel base plate, characterized in that the steel base plate includes a top plate 2 and a bottom plate 3, and the top plate 2 and the bottom plate 3 are separated by a honeycomb Shaped support plate 4 connection.

[0011] The honeycomb-shaped structural feature can guarantee to support a large weight and effectively reduce the weight, and the static electricity of friction can be quickly transmitted to the ground through the support plate 4, so that the anti-static effect is better.

[0012] Compared with the prior art, the present invention can withstand heavy pressure while ensuring the antistatic effect, and has simple principle and convenient installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com