Shielding film for exterior wall glass and preparation method thereof

A masking film and glass technology, applied in the field of masking film, can solve problems such as cumbersome cleaning work, achieve the effects of avoiding separation, ensuring uniform distribution, and enhancing anti-adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The invention provides a shielding film for exterior glass, which comprises: 31.60% polyethylene resin, 8.60% starch, 0.30% antioxidant, 0.30% ultraviolet absorber, 12.50% composite filler, 46.70% organic solvent; the composite filler includes: 17.50% hollow microspheres, 24.50% polyethylene wax, 5.40% graphite, 16.40% nano-silver particles, and 36.20% silicon dioxide by weight percentage;

[0027] The organic solvent is one or more mixtures of butyl acetate, isobutyl acetate, ethyl acetate, n-propanol, and tert-butanol; the antioxidant is: antioxidant CA, antioxidant 164, One or several kinds of antioxidant DLTP are compounded, and the ultraviolet absorbers are: 2-hydroxy-4-methoxybenzophenone, 2-hydroxy-4-n-octoxybenzophenone One or two of them are compounded;

[0028]The present invention also provides a method for preparing a masking film for exterior glass, the specific preparation steps are as follows:

[0029] Step 1: weighing the above-mentioned polyethylene r...

Embodiment 2

[0037] Different from Example 1, it includes: 32.80% polyethylene resin, 11.60% starch, 0.50% antioxidant, 0.50% ultraviolet absorber, 13.30% composite filler, 41.30% organic solvent by weight percentage ; The composite filler includes: 18.30% of hollow microbeads, 16.30% of polyethylene wax, 16.20% of graphite, 18.20% of nano-silver particles, and 31.00% of silicon dioxide in terms of weight percentage.

Embodiment 3

[0039] All different from Examples 1-2, it includes: 32.20% polyethylene resin, 10.10% starch, 0.40% antioxidant, 0.40% ultraviolet absorber, 12.90% composite filler, 44.00% organic solvent; the composite filler includes: 17.90% hollow microbeads, 15.40% polyethylene wax, 15.80% graphite, 17.30% nano silver particles, and 33.60% silicon dioxide according to weight percentage.

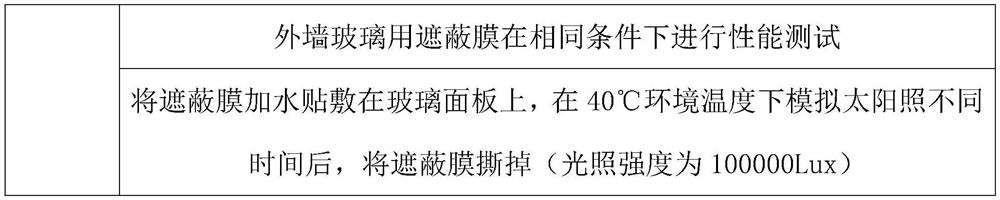

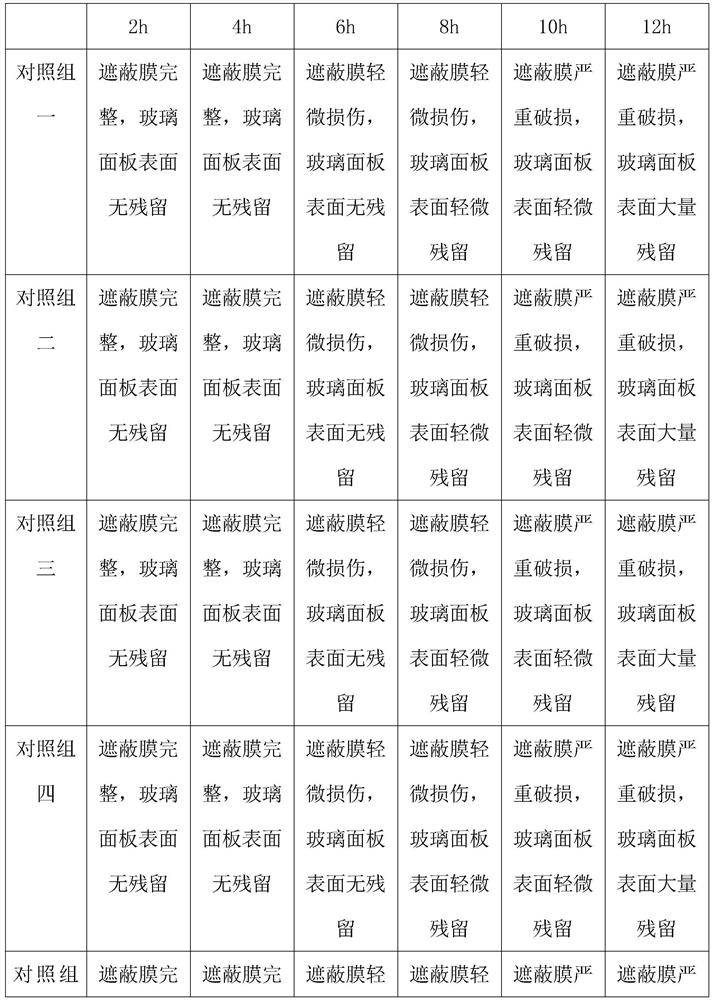

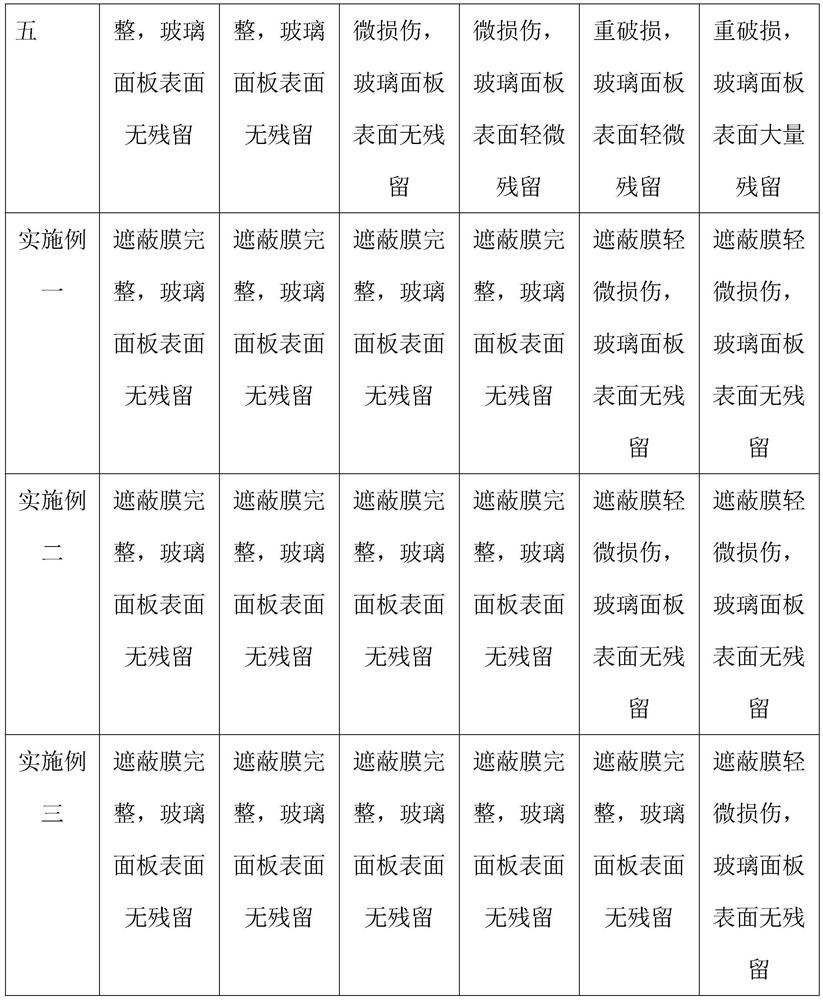

[0040] Take the masking film for exterior wall glass prepared in the above-mentioned embodiments 1-3, the masking film for exterior wall glass of control group one, the masking film for exterior wall glass of control group two, and the masking film for exterior wall glass of control group three. film, the masking film for exterior glass of control group 4 and the masking film for exterior glass of control group 5, the masking film for exterior glass of control group 1 compared with the hollow microspheres of the embodiment, and the masking film for exterior glass of control group 2 Compared with the emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com