Spliced steel platform

A steel platform, assembled technology, applied in the direction of housing structure support, housing structure support, scaffolding for housing structure support, etc., can solve problems such as platform collapse, casualties, unreliable wire rope fixation, etc., to improve work efficiency and prevent collapse. Accidents, the effect of reducing the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

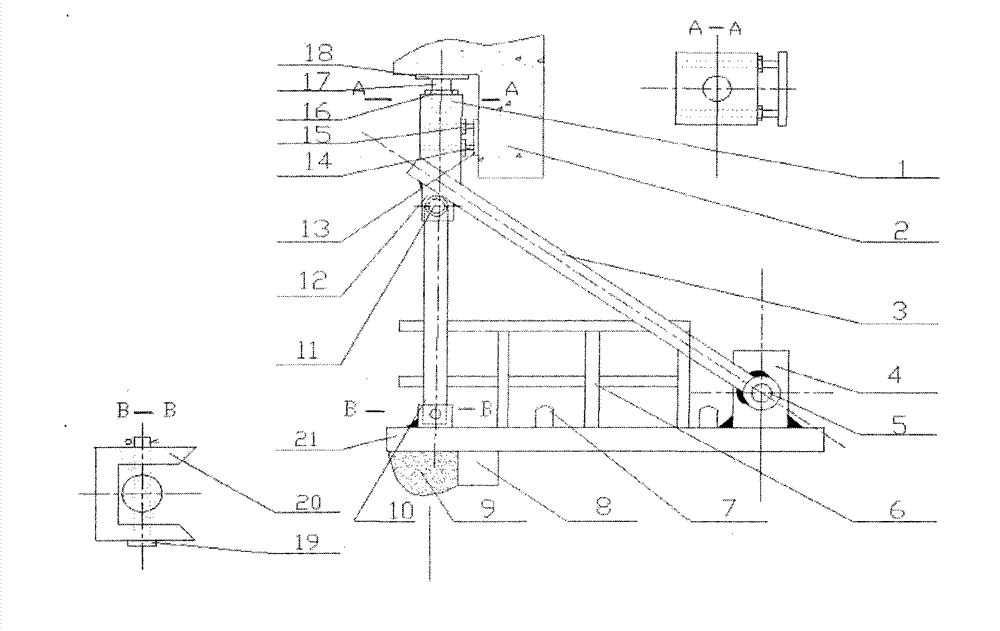

[0009] Specific implementation method: when installing the platform, lift the steel platform from the suspension ring 7 with a crane, block the block 8 on the outside of the concrete floor 9, and adjust the upper nut 16 on the adjustment block 1 to push the top plate 18 to the floor 2, Adjust the side nut 15 on the side to make the side plate 13 withstand the concrete beam 2, the lower hole of the support rod 10 is connected with the side ear plate through the lower pin shaft 19, the upper hole is connected with the ear plate 12 through the upper pin shaft 11, and the upper end of the tie rod 3 is welded with an adjustment Block 1 and ear plate 12, the lower end is connected with front ear plate 4 by pin shaft 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com