A solid-liquid mixing unidirectional force monitoring device and monitoring method

A solid-liquid mixing and monitoring device technology, applied in the field of sensing, can solve the problems of complex safety management, uneven deformation of the carrier body, pressure changes, etc., to achieve the effect of enhancing the reflection effect and solving the problem of color uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

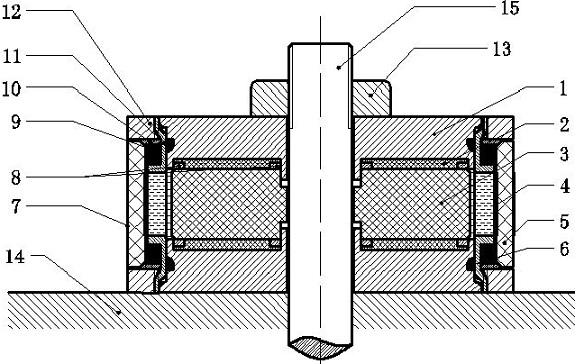

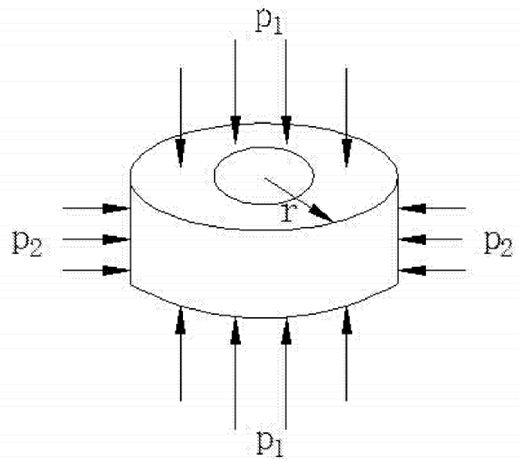

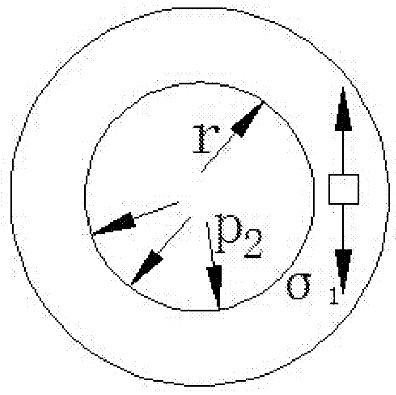

[0045] The invention provides a solid-liquid mixing unidirectional force monitoring device, such as Figure 1~5 As shown, the device includes a housing 1, the housing includes an upper housing and a lower housing, the upper and lower housings have the same structure, which is a pie-shaped ring structure, and the inner wall of the housing is provided with an inward layer of annular concave Groove, the elastic pad 2 is arranged in the groove, and the upper and lower housings respectively install the side with the elastic pad 2 on the upper and lower surfaces of the carrier 3, so that the elastic pad 2 is enclosed in the shell formed by the housing, the carrier and the sealing ring 8. In the closed cavity; the carrier body 3 is an internal hollow cylinder structure, the carrier body 3 and the upper and lower shells 1 are provided with a guide cylinder 11, and the wall of the guide cylinder 11 is provided with holes for guiding the guide cylinder Internal and external communicatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com