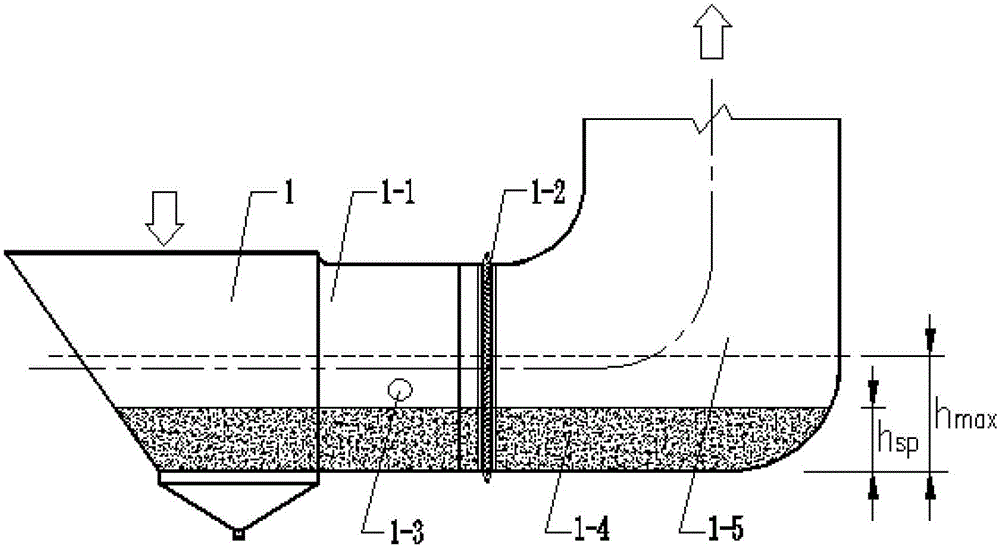

Anti-collapse device for horizontal flue in front of dust collector in thermal power plant

A technology of horizontal flue and dust collector, applied in exhaust gas device, combustion product treatment, combustion method, etc., can solve the problems of flue collapse, flue overload prevention requirements, and identification of flue dust load, etc. The effect of avoiding the collapse of the flue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

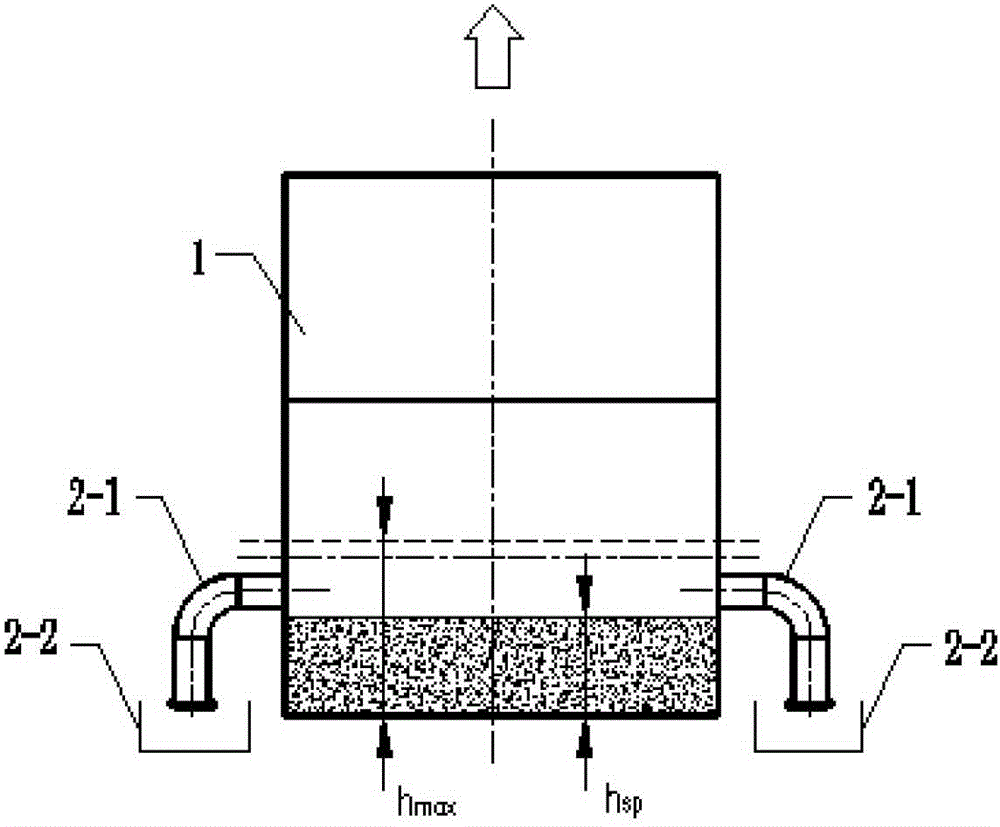

[0034] see Figure 5 As shown, one side of the bottom of the main body elbow 2-1 is provided with a magnet 2-4, and the other side is provided with a hinge 2-5, and the plug 2-2 is connected to the main body elbow 2-1 through the hinge 2-5. Movably connected together, the magnet 2-4 and the metal plug 2-2 are connected together by magnetic attraction; the magnetic attraction of the magnet 2-4 and the plug 2-2 is greater than that of the main body elbow 2-1 plus the main body The weight of dry ash filled with dry ash in elbow 2-1 is less than the weight of wet ash filled with wet ash in main elbow 2-1. The weight of plug 2-2 is the absolute value of the negative pressure of the flue multiplied by the main elbow 2-1 bottom circular cross-sectional area.

Embodiment 2

[0036] see Image 6As shown, the bottom side of the main body elbow 2-1 is provided with a spring top plate 2-9, the plug 2-2 is movably connected with the main body elbow 2-1 through the rotating shaft 2-7, and the pressing The lower end of the spring 2-8 is connected to the plug 2-2, and the upper end is connected to the spring top plate 2-9. The rigidity range of the compression spring 2-8 is greater than the weight of dry ash filled with dry ash in the main body elbow 2-1 , but less than the weight of wet ash filled with wet ash in the main body elbow 2-1; the weight of the bottom plug 2-2 is the absolute value of the negative pressure of the flue multiplied by the circular cross-sectional area at the bottom of the main body elbow 2-1.

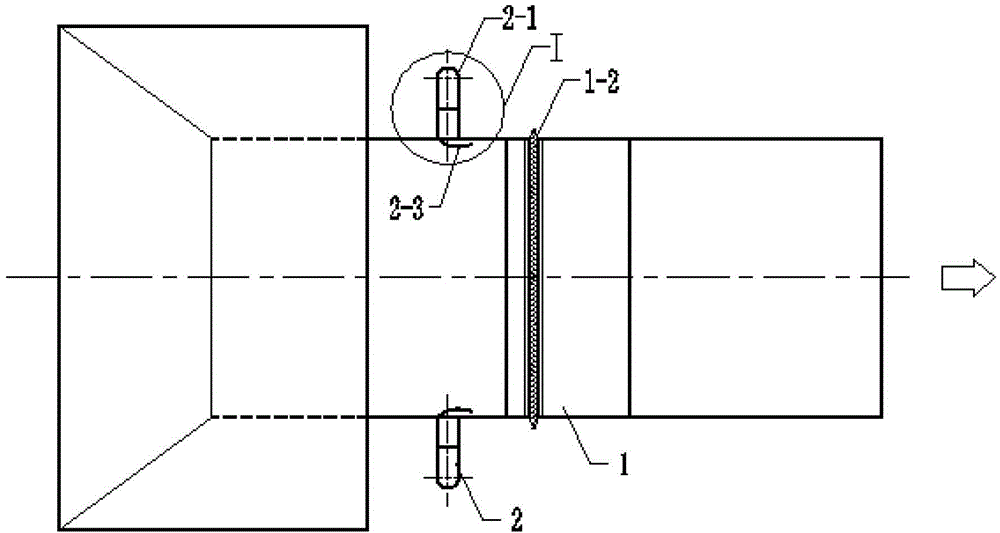

[0037] The working principle of the embodiment of the present invention: due to the possibility of local uneven height due to ash accumulation, an anti-collapse device 2 is installed on both sides of the flue. Due to the diffusion effect, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com