Railcar bogie

一种铁道车辆、转向架的技术,应用在铁道车辆用转向架领域,能够解决钢材成本和组装成本变高、转向架构架重量增大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, embodiments according to the present invention will be described with reference to the drawings.

[0031] (first embodiment)

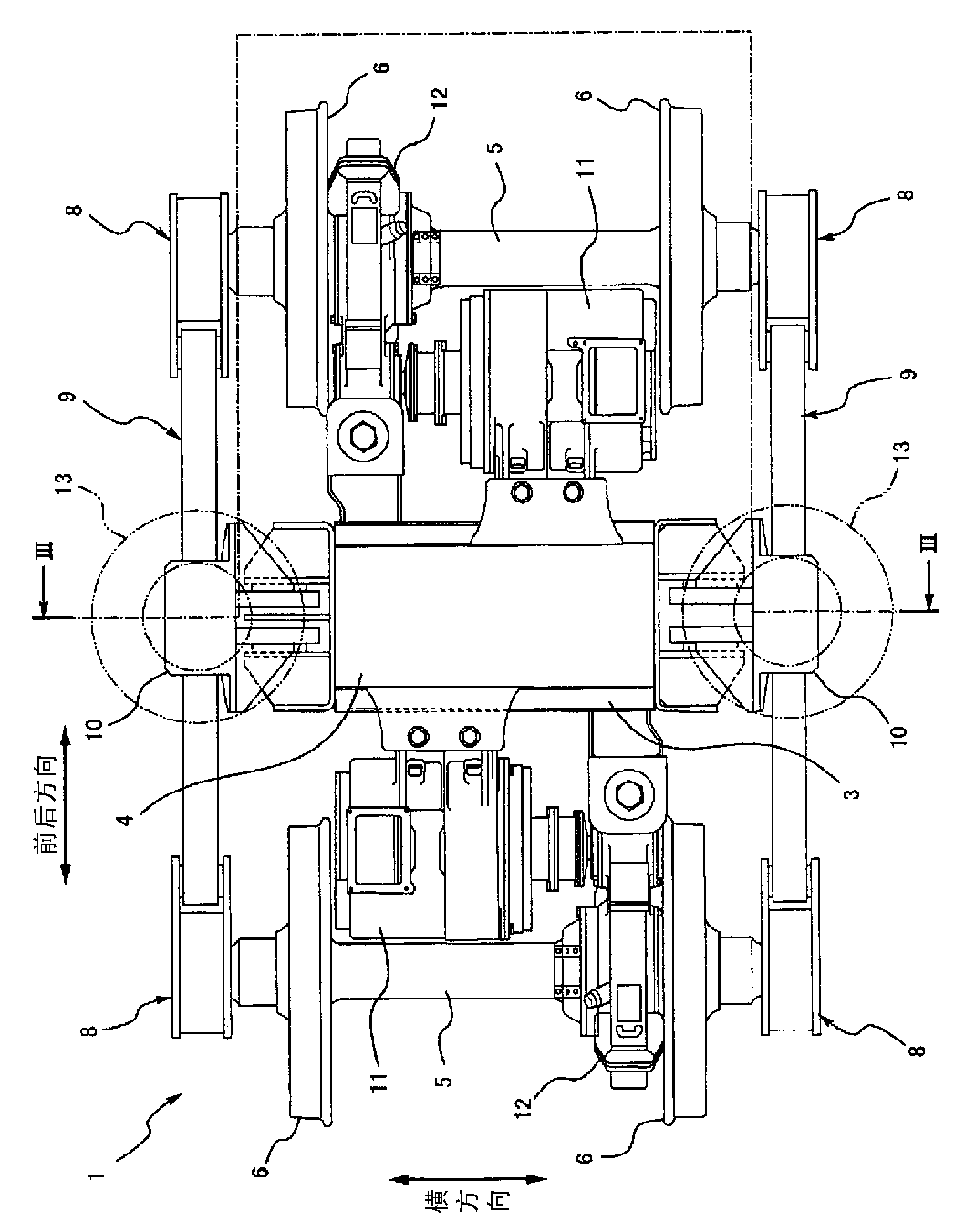

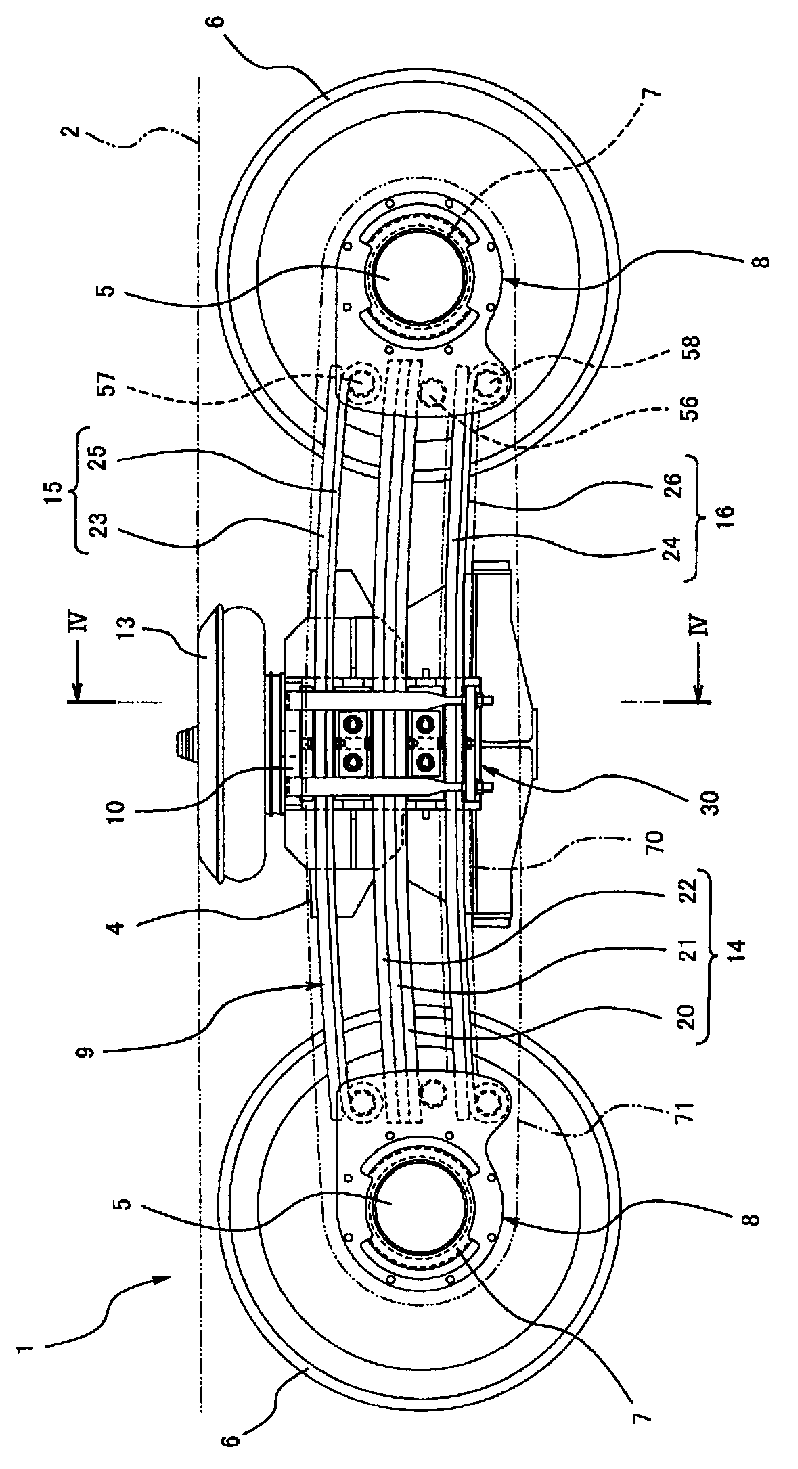

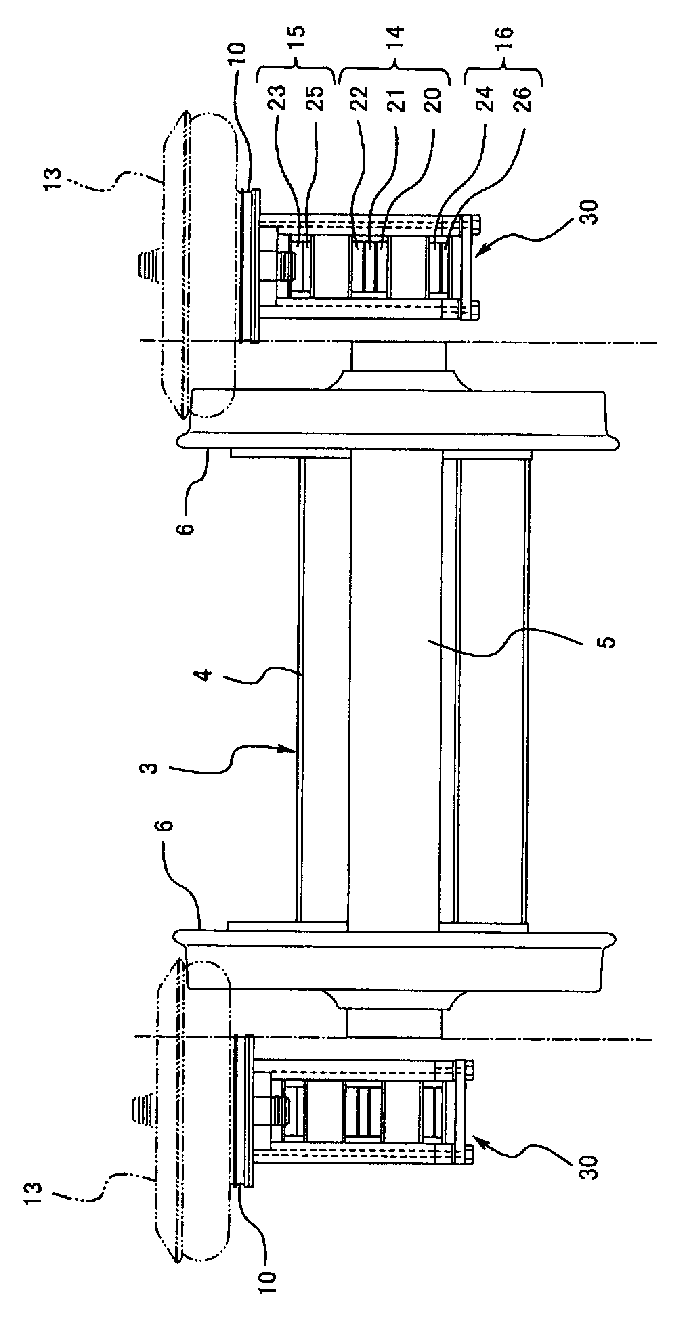

[0032] figure 1 It is a plan view of the railway vehicle bogie 1 according to the first embodiment of the present invention. figure 2 yes figure 1 The shown side view of the bogie 1 for a railway vehicle. image 3 yes figure 1 The illustrated bogie 1 for a railway vehicle is a cross-sectional view taken along line III-III. Such as Figure 1 ~ Figure 3 As shown, the railway car bogie 1 includes a transverse beam 4 extending in the lateral direction as a truck frame 3 for supporting the vehicle body 2 , but does not include side beams extending in the front-rear direction from both ends of the beam 4 . Front and rear of the beam 4, a pair of front and rear axles 5 are arranged along the transverse direction, and wheels 6 are fixed on both sides of the axle 5 in the transverse direction. Bearings 7 , which rotatably support the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap