Defective electrode winding device

An electrode roll, bad technology, applied in the direction of winding strips, transportation and packaging, assembling battery machines, etc., can solve problems such as hindering normal electrode winding, and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

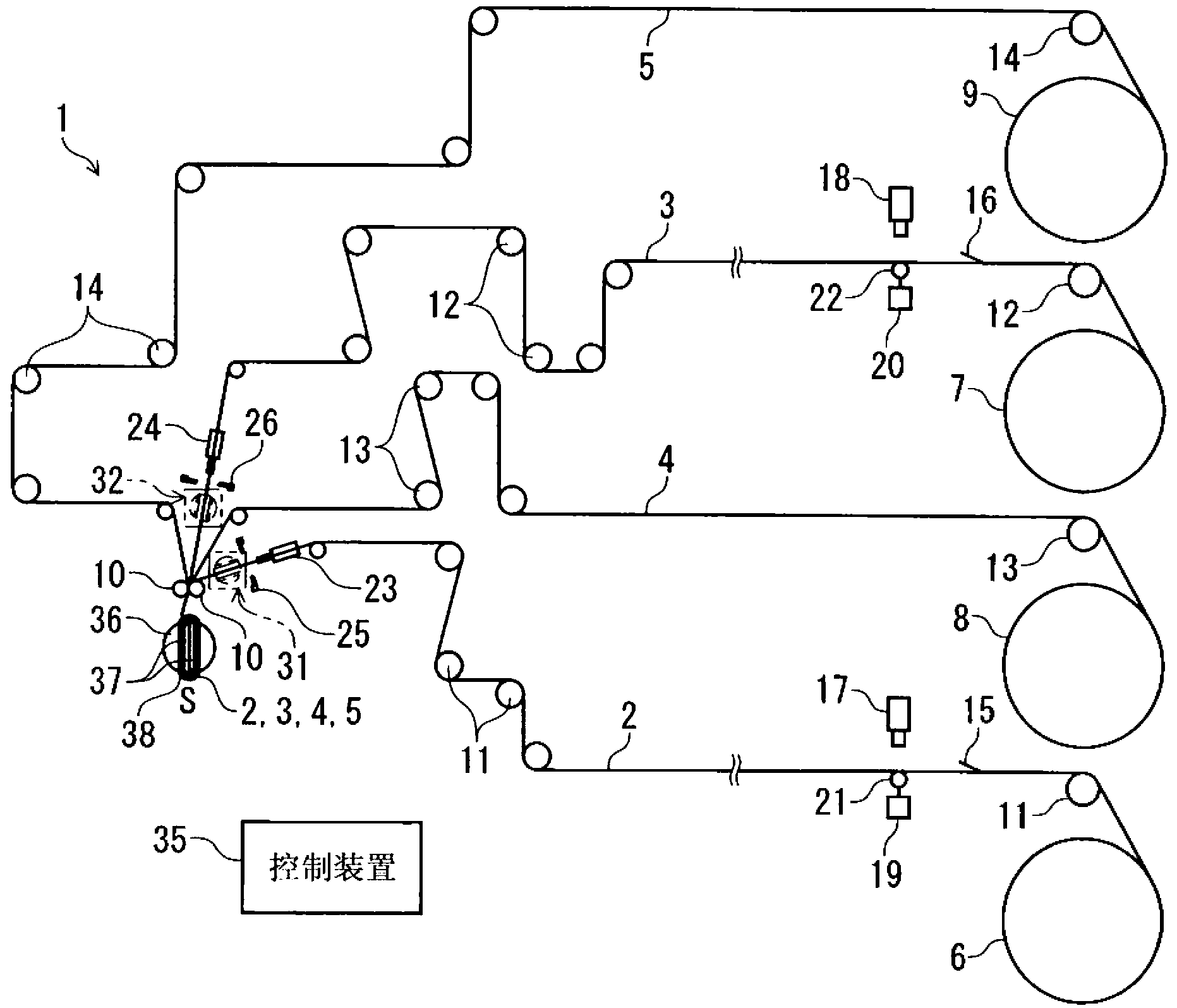

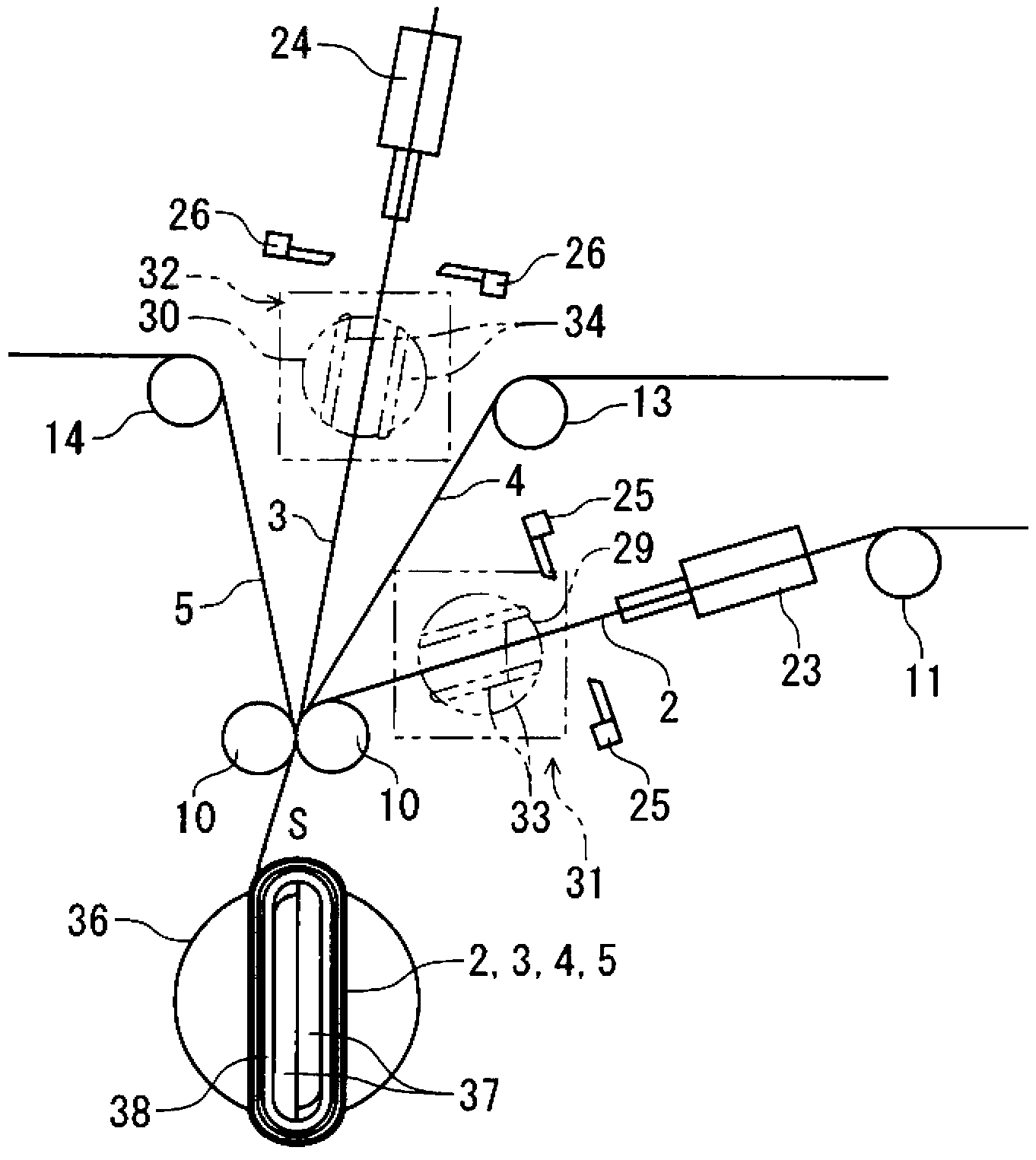

[0029] Based on the invention figure 1 with figure 2 In the electrode winding device 1 shown, the strip-shaped positive electrode side electrode 2 and the negative electrode side electrode 3 and the strip separators 4 and 5 for insulation to be sandwiched between the pair of electrodes 2 and 3 are removed from the corresponding coils. The discs 6, 7, 8, 9 are sent out, and are guided between a pair of nip rollers 10 by a plurality of guide rollers 11, 12, 13, 14, and floating rollers (not shown) provided as necessary, and pass The pair of nip rollers 10 are finally wound on the outer peripheral surface of the core 38.

[0030] When necessary, a pair of nip rollers 10 are arranged near the finished product winding position S in such a way that at least one of the nip rollers 10 can contact and be separated from the other.

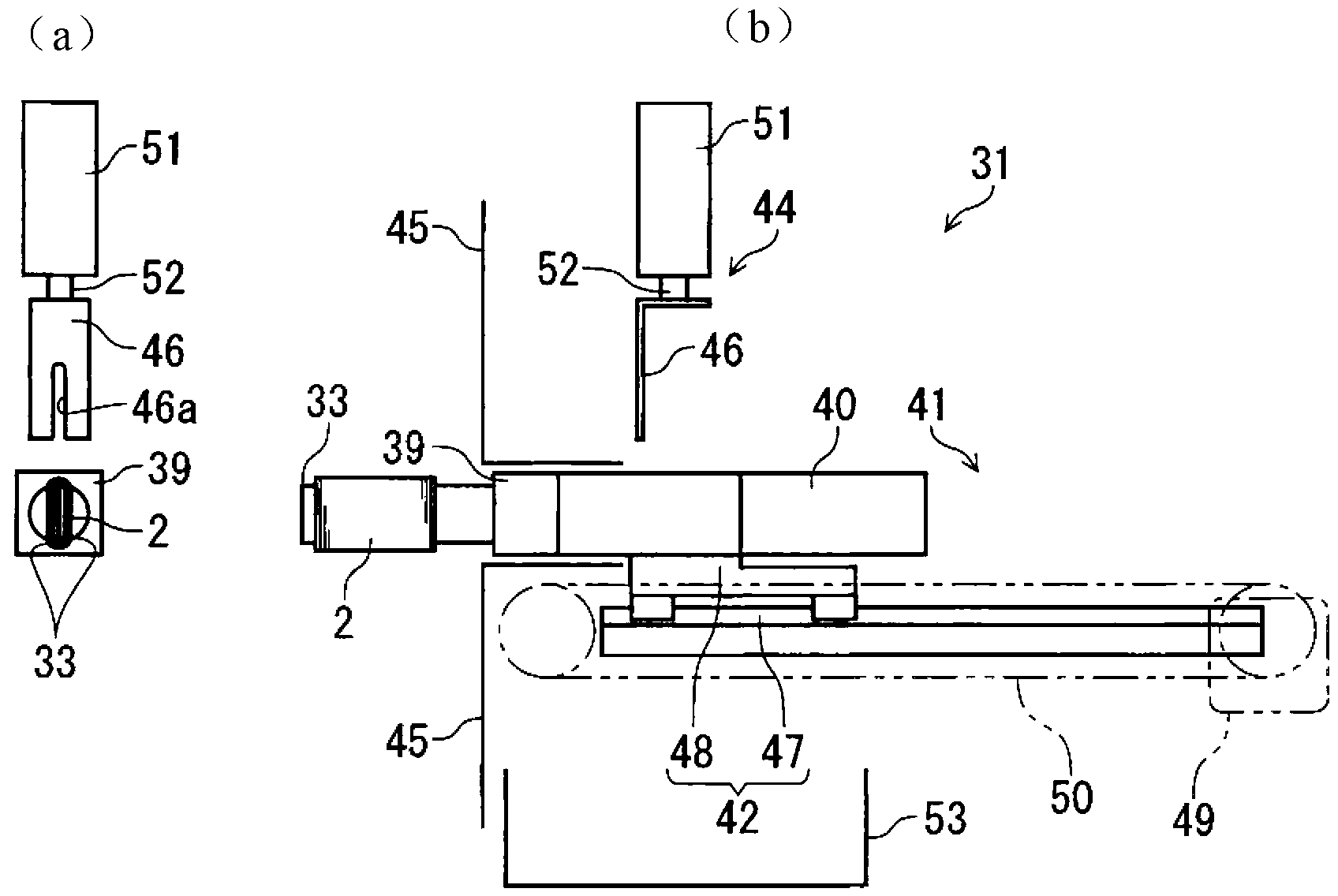

[0031] Each electrode 2 or 3 passes in front of the electrode holder 23 or 24, the pair of electrode cutters 25 or 26, and the defective electrode winding devic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap