Sound-free elastic point type multi-fastening floor board

An elastic and point-type technology, applied in the direction of elastic floors, floors, buildings, etc., can solve problems such as production troubles, inability to process, and insufficient lock locks, etc., to achieve the effect of easy production and processing, easy processing and production, and tight locks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

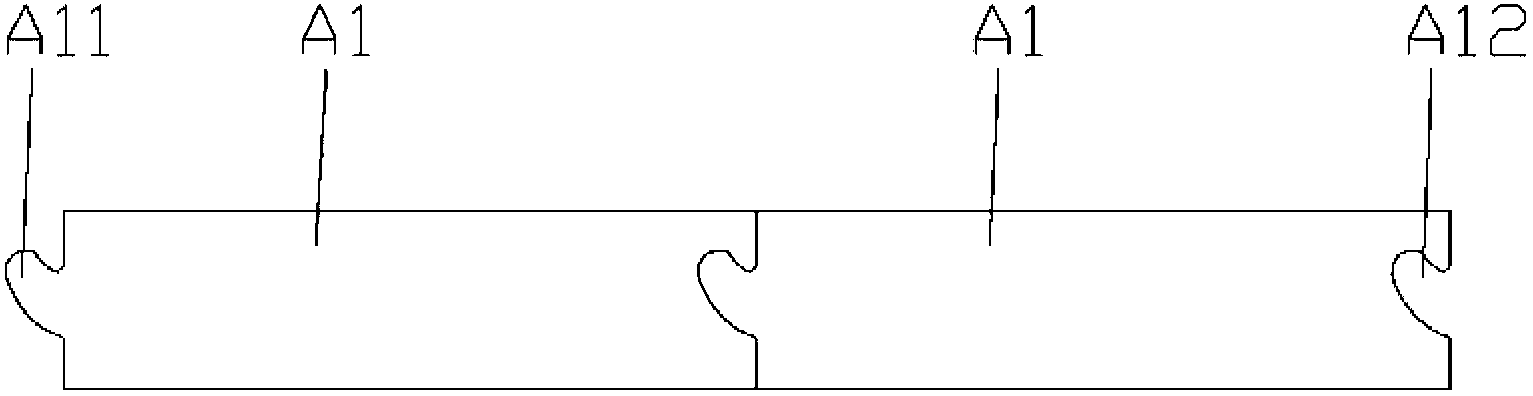

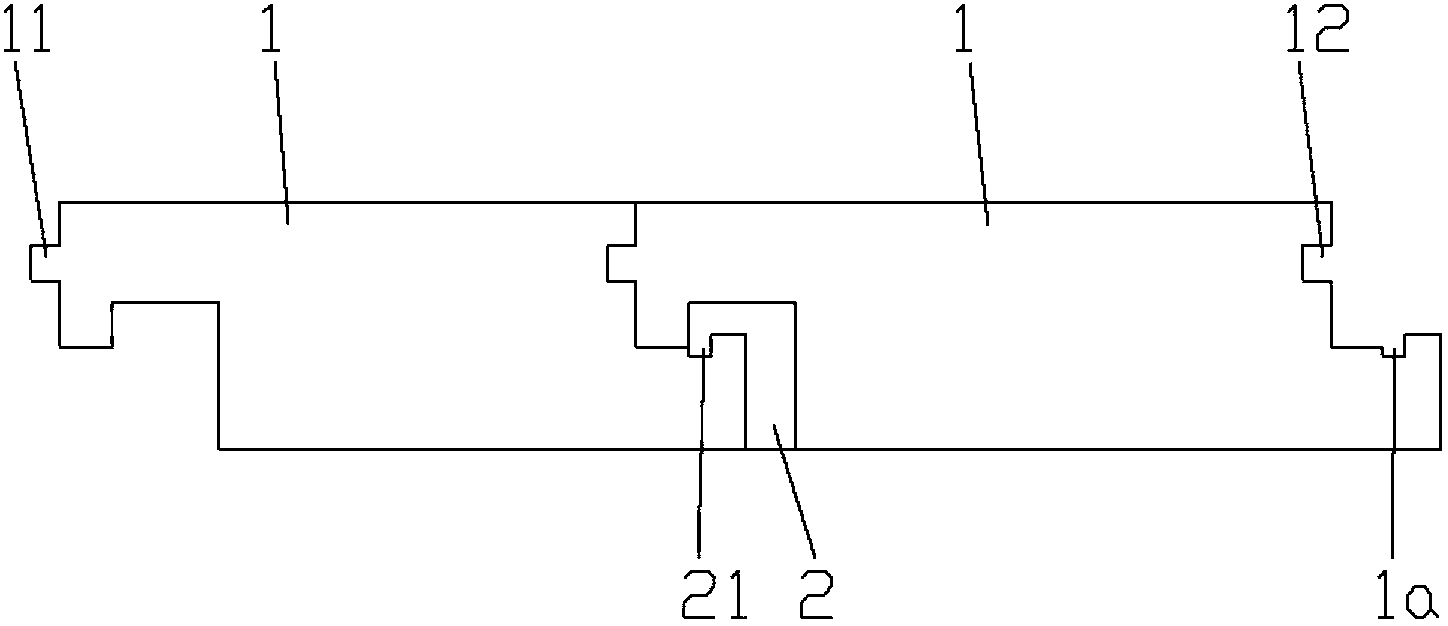

[0034] Example 1, see figure 1 As shown, a point-type multi-lock floor with no noise and elasticity, including wooden boards 1 and keels 2, each wooden board 1 is formed with a horizontal straight tenon 11 at one end, and a horizontal straight tenon groove 12 at the other end. The horizontal straight tenon 11 on the two adjacent wooden boards 1 is inserted into the horizontal straight tenon groove 12;

[0035] The main reinforcement of the keel 2 is 7-shaped, and the main reinforcement of the keel 2 has a downward front hook straight tenon 21, and a front hook straight tenon groove 1a matched with the front hook straight tenon 21 is formed on the wooden board 1, and the front hook The straight tenon 21 of the front hook is inserted into the straight tenon groove 1a of the front hook.

Embodiment 2

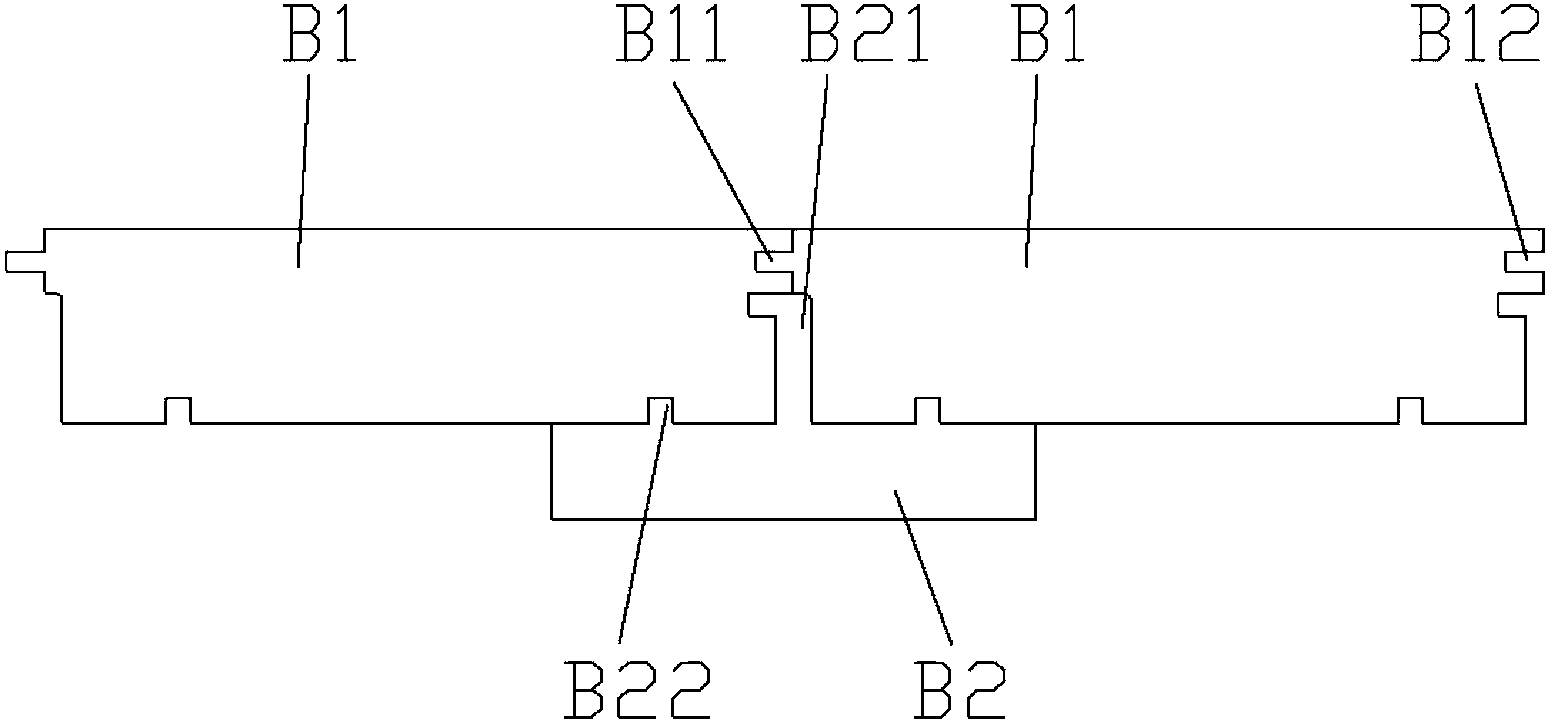

[0036] Example 2, see Figure 4 As shown, the keel 2 is formed with a keel transverse straight tenon 23, and the keel transverse straight tenon 23 is inserted into the matching keel transverse straight tenon groove 1C on the wooden board 1. All the other are with embodiment 1.

Embodiment 3

[0037] Example 3, see Figure 5 As shown, the keel 2 is formed on a square block 3 . All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com