Oil and gas well downhole casing string distributed optical cable whole process online stress detection device

A technology for stress detection and oil and gas wells, which is applied in construction and other fields, can solve the problems of inability to detect the stress of the casing string at the full depth of the well, the inability to detect the amount of deformation, and the inability to detect the on-line stress of the casing string, so as to reduce the overall cost and improve the detection. Effect of Efficiency and Detection Range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0030] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

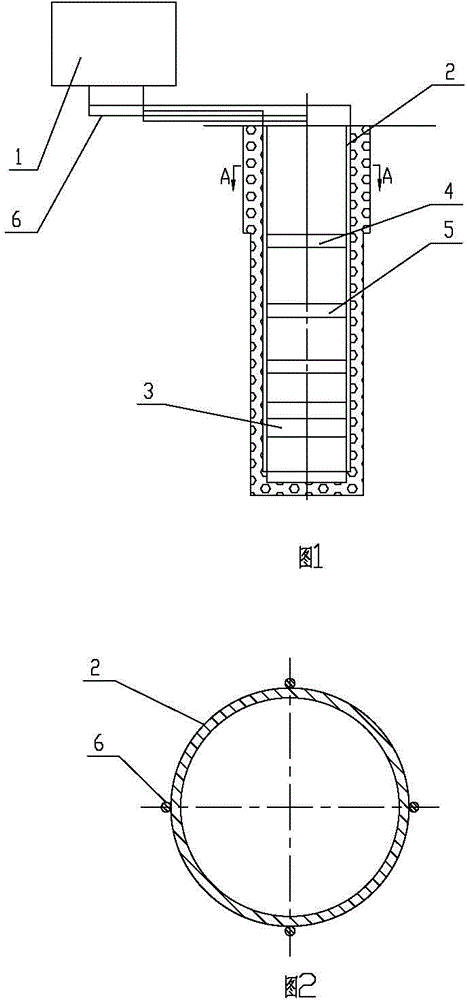

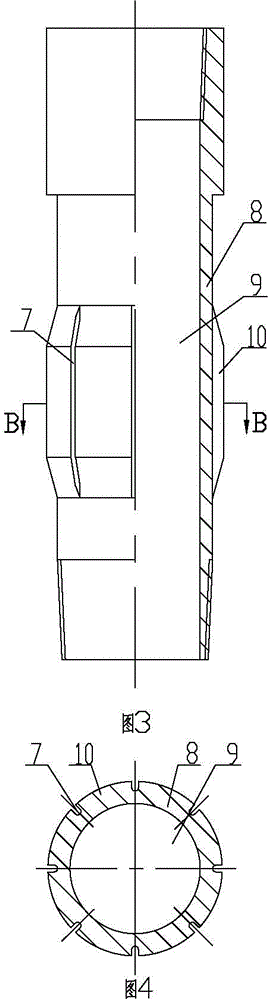

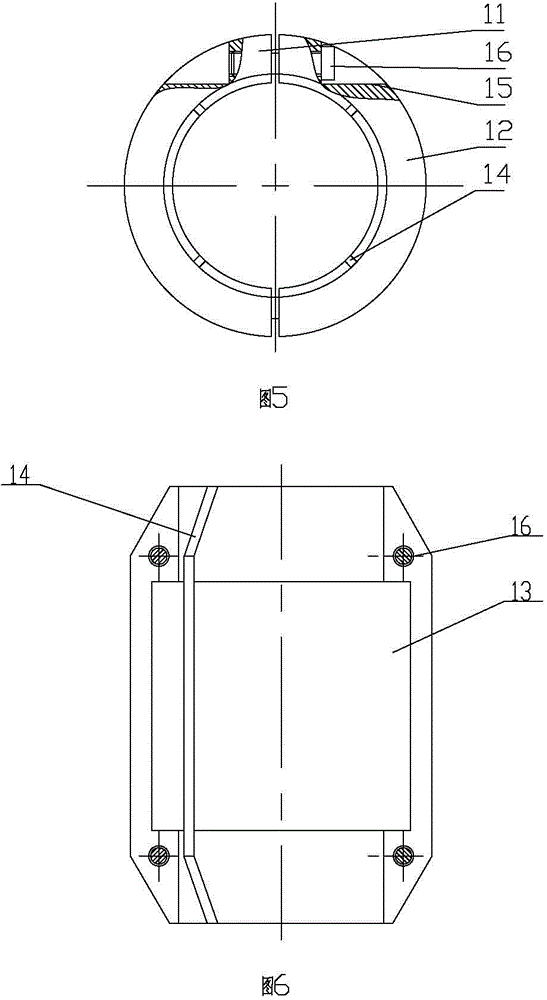

[0031] as attached figure 1 , 2 , 3, 4, 5, 6, 7, 8, 9, and 10, the oil and gas well downhole casing string distributed optical cable full-range on-line stress detection device includes Brillouin optical time domain analyzer 1, integrated detection short Section 3 and at least four bushings 2; at least two pairs of adjacent bushings 2 are fixedly installed with coupling-type short joints 3, and the remaining adjacent bushings 2 are fixedly installed together through collars. At least two U-shaped and axially symmetrical axial optical cables 6 are fixedly installed on the outer side of the pipe 2, the joint-type detection nipple 3 and the collar, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com