Compound hydraulic oscillating cylinder for electro-hydraulic servo loading systems

A technology of loading system and hydraulic swing, applied in the direction of fluid pressure actuating device, etc., to achieve the effect of reducing pressure loss along the process, good process performance, and ensuring no leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

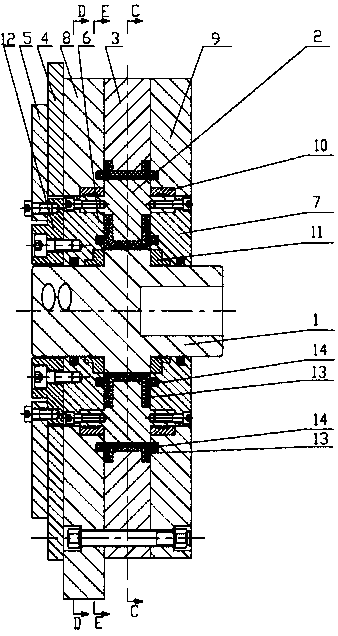

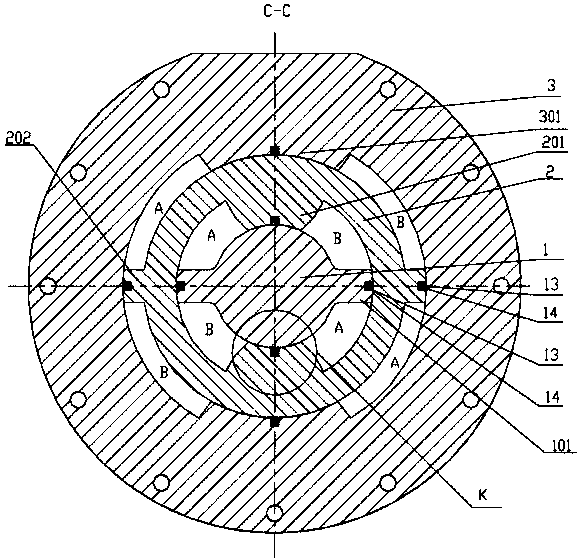

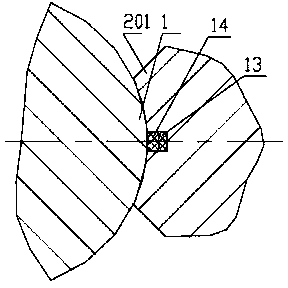

[0040] Such as figure 1 As shown, a compound hydraulic swing cylinder for an electro-hydraulic servo loading system includes a loading cylinder shaft 1, a loading cylinder housing 2, a synchronous cylinder housing 3, an induction synchronizer stator 4, an induction synchronizer rotor 5, and a left end cover of the loading cylinder 6. The right end cover 7 of the loading cylinder, the left end cover 8 of the synchronous cylinder and the right end cap 9 of the synchronous cylinder, the thrust bearing I10 and the thrust bearing II11; among them: the synchronous cylinder shell 3 has a cavity, and the loading cylinder shell 2 is also used as a synchronous cylinder The rotor is placed in the cavity of the synchronous cylinder housing 3, and the thrust bearing I10 is set on the outer surface of the loading cylinder housing 2. The synchronous cylinder housing 3, the left end cover 8 of the synchronous cylinder and the right end cover 9 of the synchronous cylinder also serve as thrust b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com