Hydraulic rotary joint

A rotary joint and hydraulic technology, applied in the direction of flexible/rotatable line connectors, connections, electrical components, etc., can solve the problems of easy oil leakage of rotary joints, influence of rotary body and rotary shaft, short life of pipelines, etc., to ensure high performance, reduced labor intensity, and long pipeline life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

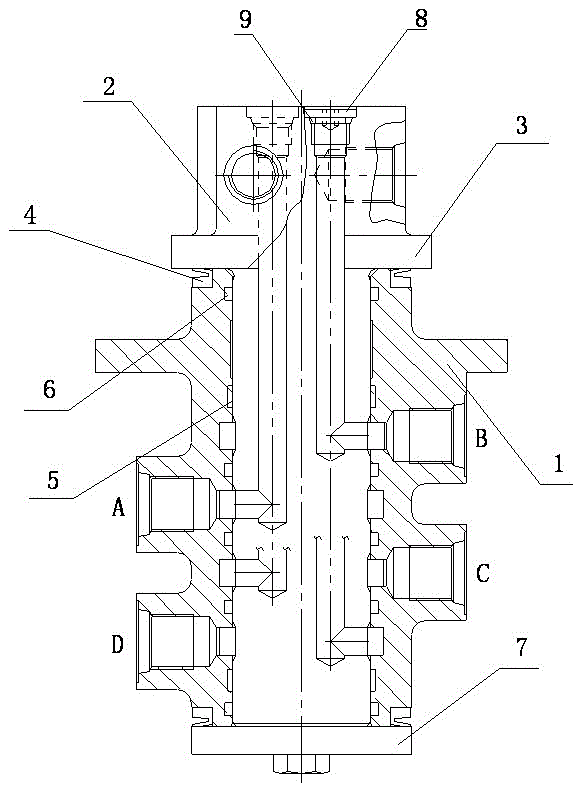

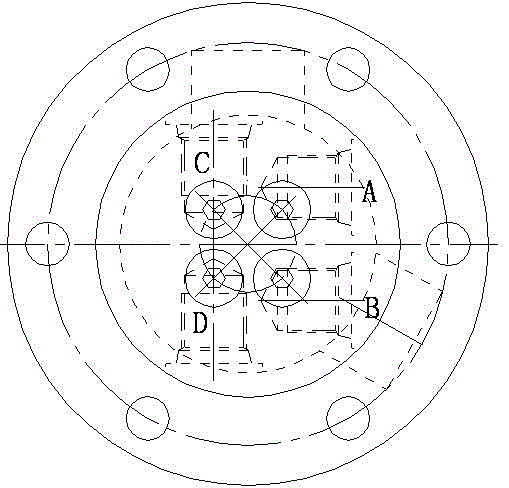

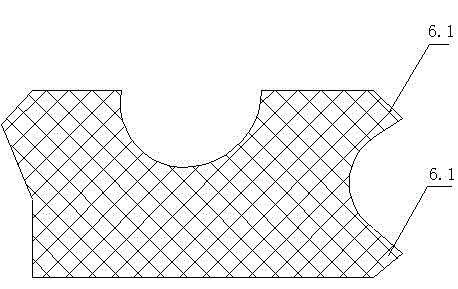

[0015] see Figure 1 to Figure 3 , the present invention relates to a hydraulic rotary joint, comprising a rotary body 1 and a rotary shaft 2, the bottom end of the rotary shaft 2 is axially inserted from the top end of the rotary body 1, and the top end of the rotary shaft 2 is exposed from the rotary body 1, A flange 3 is provided between the top of the rotary body 1 and the rotary shaft 2, a water seal ring 4 is provided between the bottom surface of the flange 3 and the top of the rotary shaft 2, and a water seal ring 4 is provided at the bottom of the rotary shaft 2. There is a bottom plate 7, and the bottom plate 7 is fixed to the bottom end of the rotary shaft 2 through bolts and washers, and a rotary sealing ring 5 and a dustproof sealing ring 6 are installed in the annular groove between the rotary body 1 and the rotary shaft 2. The side of the dust-proof sealing ring 6 in contact with the rotary shaft 2 is provided with two upper and lower lips 6.1 to form a double l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com