Crosswise heterogeneous electron irradiation method of improving global completion table (GCT) chip safe working area

A technology of safe working area and electron irradiation, applied in the manufacturing of circuits, electrical components, semiconductor/solid-state devices, etc., can solve problems such as the improvement bottleneck of the batch safe working area of IGCT devices, reduce the redistribution effect, and improve the overall Safe working area, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

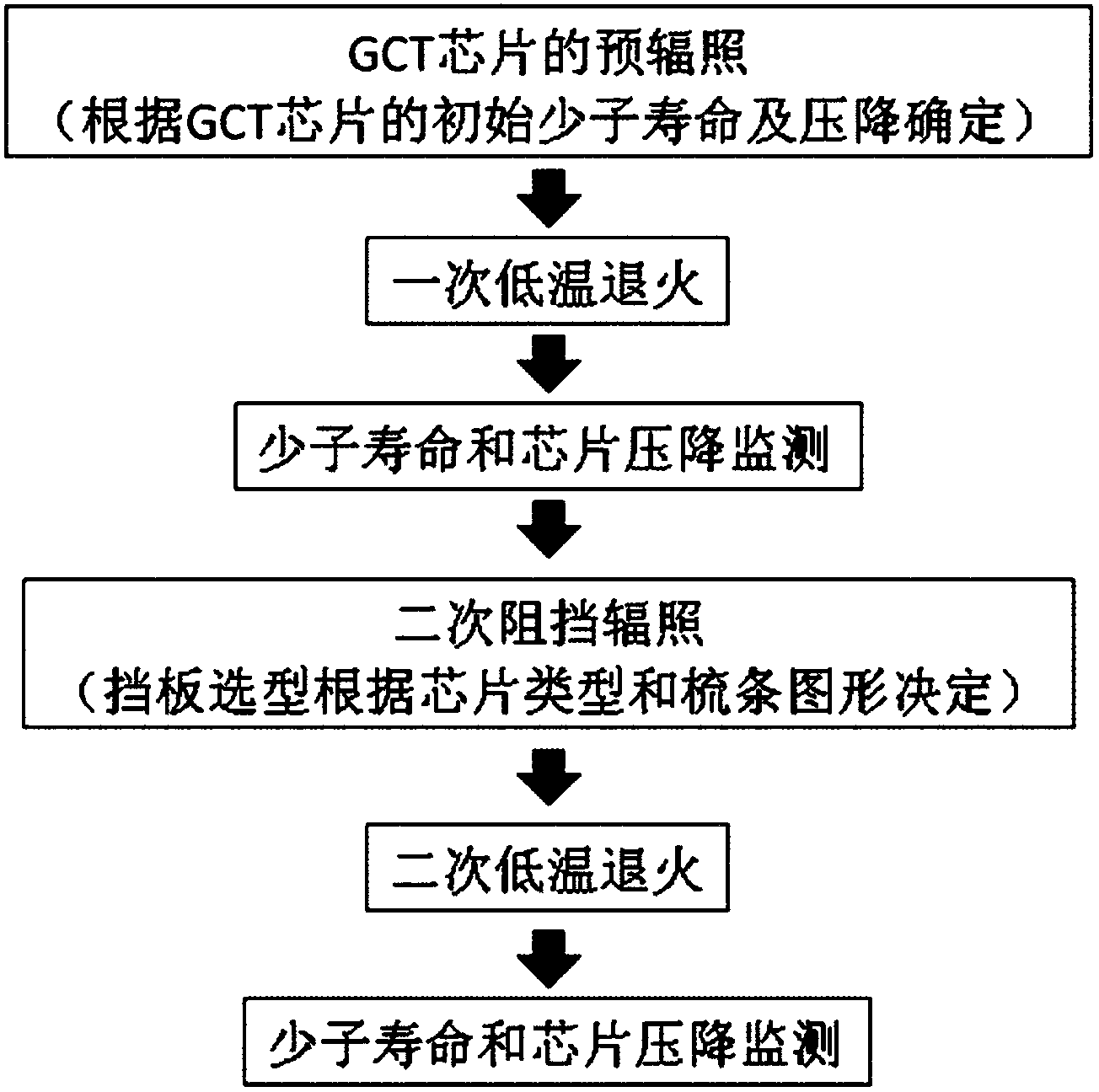

[0035] Such as figure 1As shown, the present invention is a method for improving the lateral non-uniform electron irradiation of the GCT chip safe working area, and its steps are:

[0036] (1) Pre-irradiation of GCT chips. By controlling the minority carrier lifetime and voltage drop of the chip, a pre-irradiation is performed on the GCT chip.

[0037] (2) After primary annealing, monitor the minority carrier lifetime and chip voltage drop.

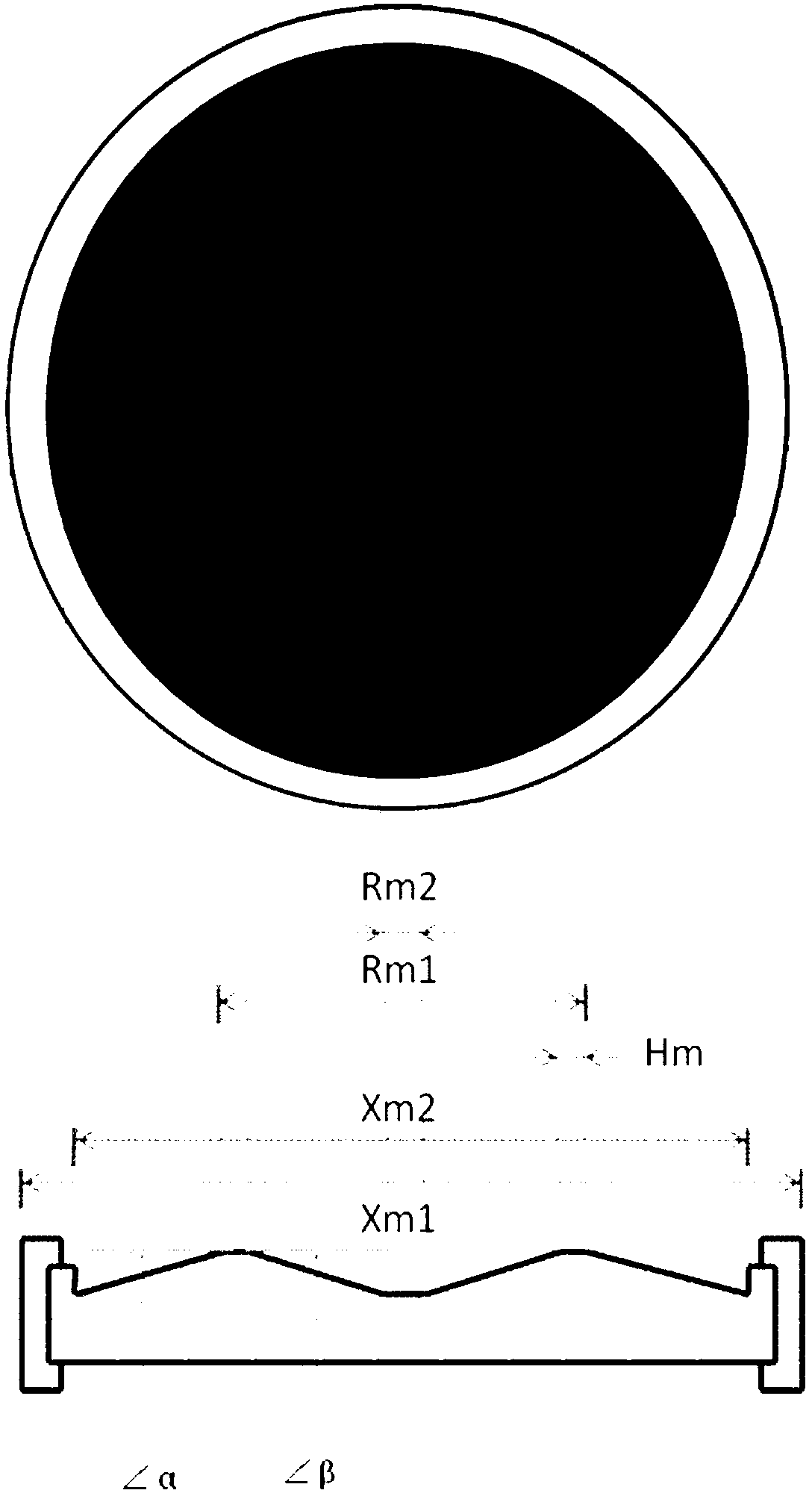

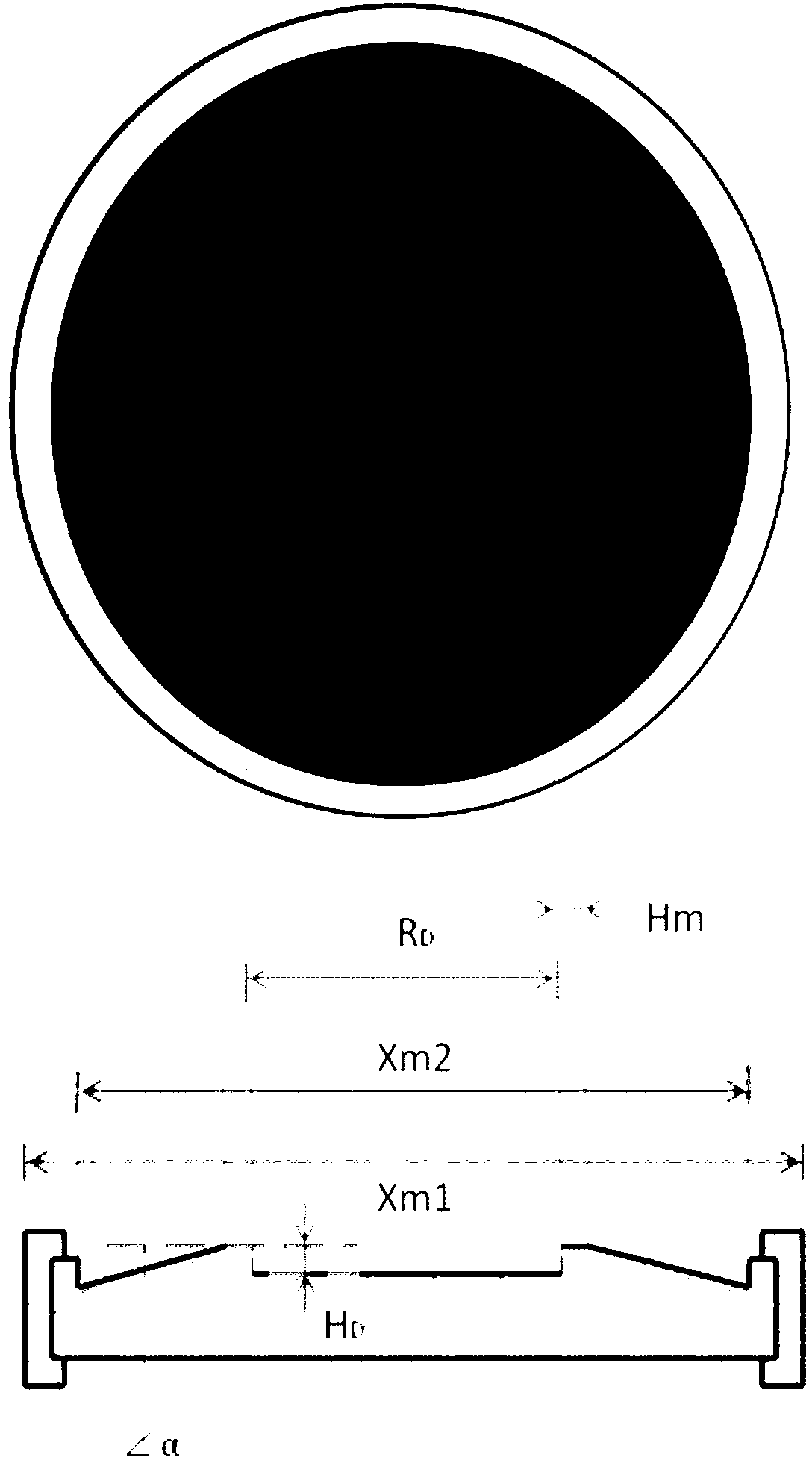

[0038] (3) The composite alloy baffle is used, and the GCT chip is irradiated twice and annealed by using the non-uniformity of the electron irradiation to penetrate the composite alloy baffle, so as to achieve the minority carrier lifetime and pressure drop requirements of the GCT chip. The type of the composite alloy baffle can be determined according to the chip type and the sliver pattern....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com