Vertically placing mechanical press fitting structure of power device clusters

A power device, vertical placement technology, applied in the direction of electric solid device, semiconductor device, semiconductor/solid state device components, etc., can solve the problem of undiscovered patent documents, etc., to avoid uneven force on the device and reduce the thickness of the board , The effect of increasing support strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following describes the embodiments of the present invention in detail with reference to the accompanying drawings; it should be noted that this embodiment is narrative and not restrictive, and the protection scope of the present invention cannot be limited by this.

[0020] This embodiment takes an IGCT power cell string as an example for description.

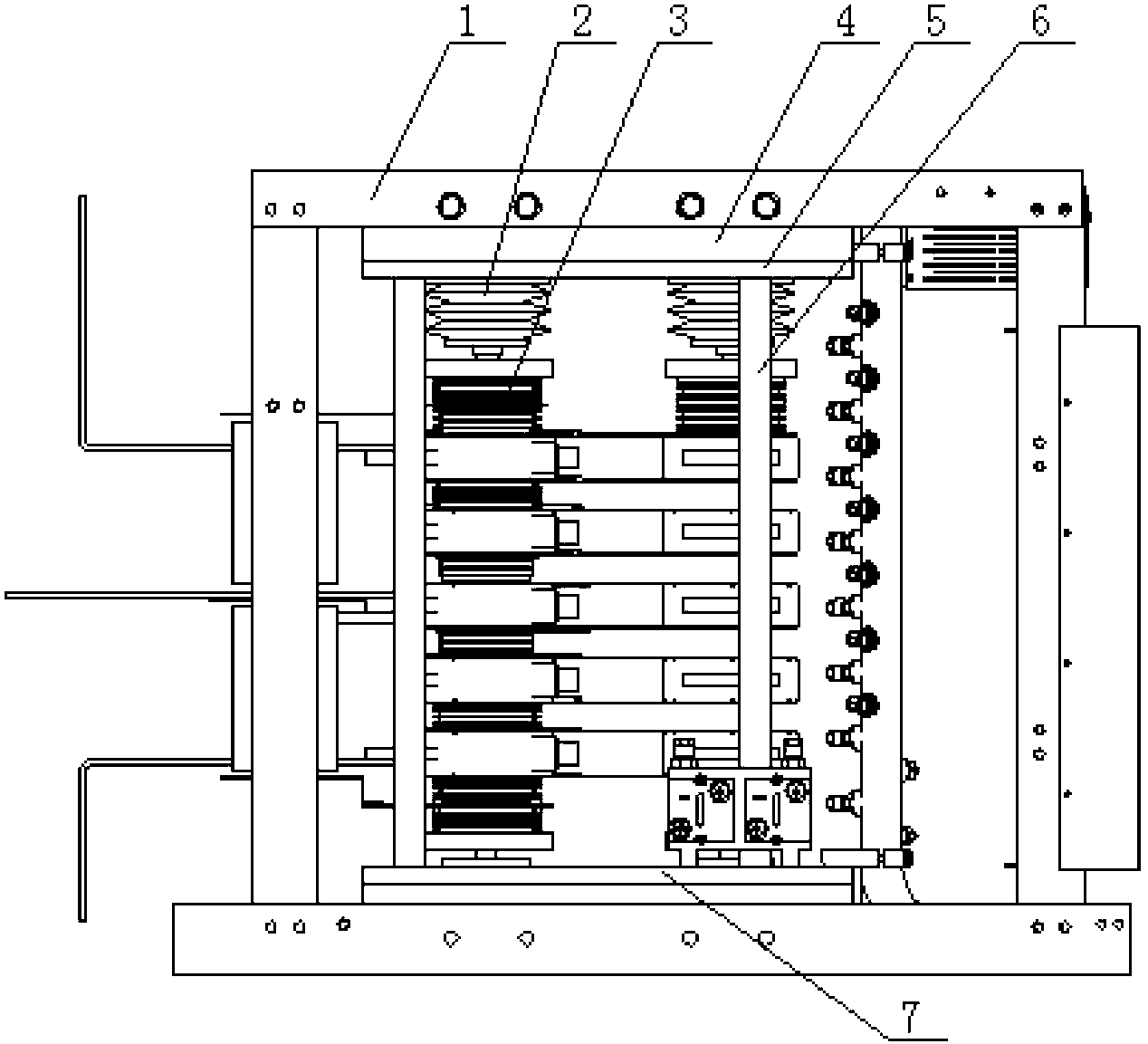

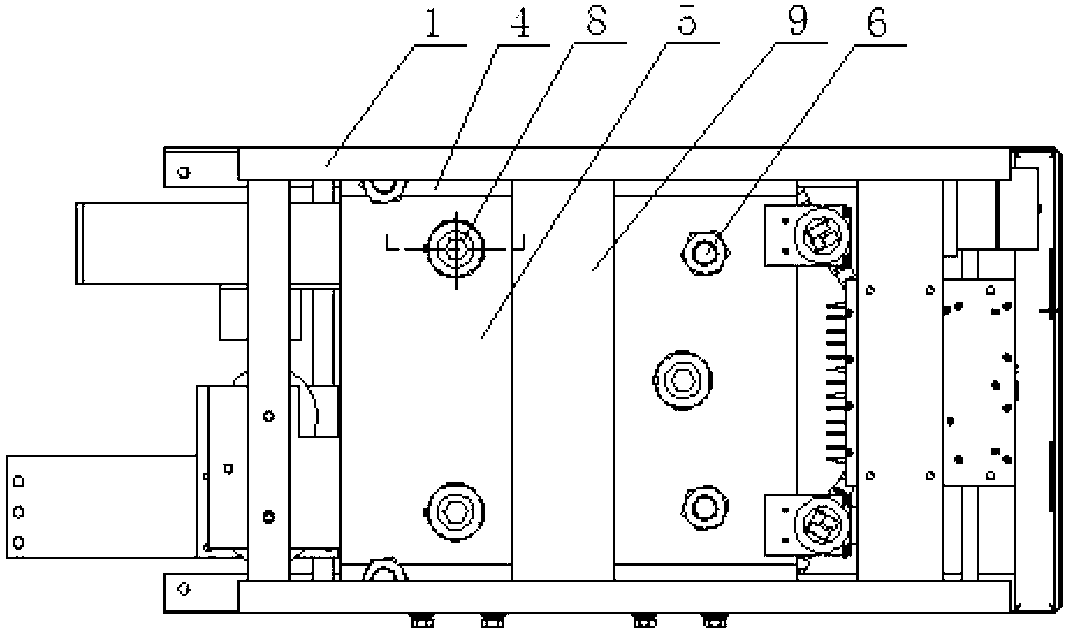

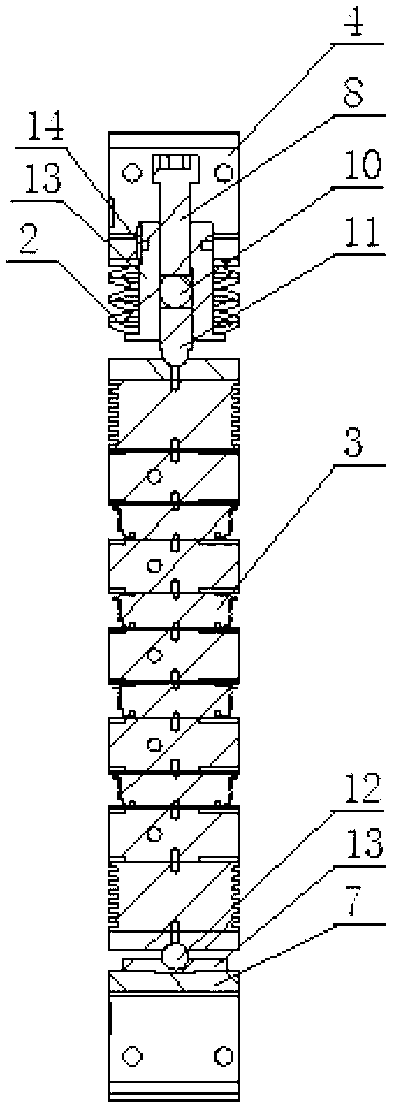

[0021] A power device string vertically placed mechanical pressing unit structure, including a square frame 1, a top plate 5, a bottom plate 7 and a power device string 3. The bottom plate is fixed at the bottom of the square frame, and the top plate is fixed at the upper end of the square frame , The bottom plate and the top plate are arranged in parallel, and a plurality of power device strings and other auxiliary parts such as insulating pads, bus bars, etc. are installed vertically between the top plate and the bottom plate. The specific structure of the top plate, bottom plate and square frame installation is:

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com