Ni-base high-temperature-resistant alloy and preparation method thereof

A high temperature resistant alloy and alloy technology, applied in the field of high temperature materials, can solve the problems of high temperature durability and high temperature mechanical properties that cannot fully meet the needs of engines and gas turbines, and achieve good mechanical properties, uniform distribution, and long high temperature durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

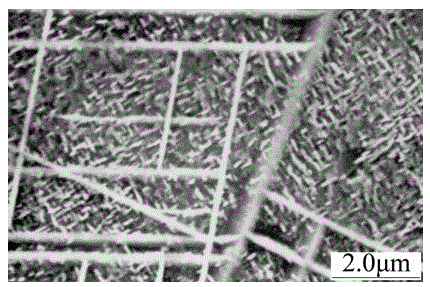

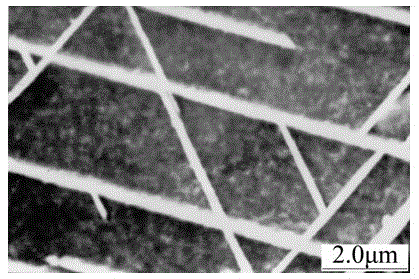

Image

Examples

Embodiment 1

[0018] Formula 1: C 0.03%, Cr 18.8%, Co 12%, Nb 4.5%, Mo 3.2%, Al 0.5%, Ti 1.0%, Ta 3.0%, B 0.008%, and Ni.

[0019] According to formula 1, the ingredients are put into a vacuum induction furnace for smelting to obtain alloy liquid. The molten alloy is cast at a casting temperature of 1390°C and a mold temperature of 960°C, and cooled to room temperature within about 10 minutes to obtain an alloy ingot.

[0020] The alloy ingots are processed in turn as follows:

[0021] Pre-treatment: Put the alloy ingot in a heat treatment furnace, heat up to 1140°C, keep it warm for 4 hours, homogenize the alloy, take it out and cool it in air; put the alloy ingot in a heat treatment furnace, heat it up to 1090°C, keep it warm for 1 hour, take it out air cooled.

[0022] Intermediate treatment: place the alloy ingot in a heat treatment furnace, heat it up to 950°C, keep it warm for 2 hours, take it out and cool it in air.

[0023] Aging treatment: put the alloy ingot in a heat treatment...

Embodiment 2

[0025] Formulation 2: C 0.03%, Cr 18.8%, Co 12%, Nb 4.8%, Mo 3.2%, Al 0.5%, Ti 1.0%, Ta 3.0%, B 0.010%, and Ni.

[0026] According to formula 2, the ingredients are put into a vacuum induction furnace for smelting to obtain alloy liquid. The molten alloy is cast at a casting temperature of 1390°C and a mold temperature of 960°C, and cooled to room temperature within about 10 minutes to obtain an alloy ingot.

[0027] The alloy ingots are processed in turn as follows:

[0028] Pre-treatment: Put the alloy ingot in a heat treatment furnace, heat up to 1140°C, keep it warm for 4 hours, homogenize the alloy, take it out and cool it in air; put the alloy ingot in a heat treatment furnace, heat it up to 1090°C, keep it warm for 1 hour, take it out air cooled.

[0029] Intermediate treatment: place the alloy ingot in a heat treatment furnace, heat up to 955°C, keep it warm for 2 hours, take it out and cool it in air.

[0030] Aging treatment: put the alloy ingot in a heat treatmen...

Embodiment 3

[0032] Formulation 3: C 0.03%, Cr 18.8%, Co 12%, Nb 4.6%, Mo 3.2%, Al 0.5%, Ti 1.0%, Ta 2.5%, B 0.011%, and Ni.

[0033] According to formula 1, the ingredients are put into a vacuum induction furnace for smelting to obtain alloy liquid. The molten alloy is cast at a casting temperature of 1390°C and a mold temperature of 960°C, and cooled to room temperature within about 10 minutes to obtain an alloy ingot.

[0034] The alloy ingots are processed in turn as follows:

[0035] Pre-treatment: Put the alloy ingot in a heat treatment furnace, heat up to 1140°C, keep it warm for 4 hours, homogenize the alloy, take it out and cool it in air; put the alloy ingot in a heat treatment furnace, heat it up to 1090°C, keep it warm for 1 hour, take it out air cooled.

[0036] Intermediate treatment: place the alloy ingot in a heat treatment furnace, heat up to 950°C, keep it warm for 2 hours, take it out and cool it in air.

[0037] Aging treatment: put the alloy ingot in a heat treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com