Drainage stop valve

A technology of stop valve and valve cavity, which is applied in the direction of valve lift, valve detail, valve device, etc., can solve the problem that the control valve cannot realize fast sewage discharge, and achieve the effects of high utilization rate, rapid sewage discharge and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

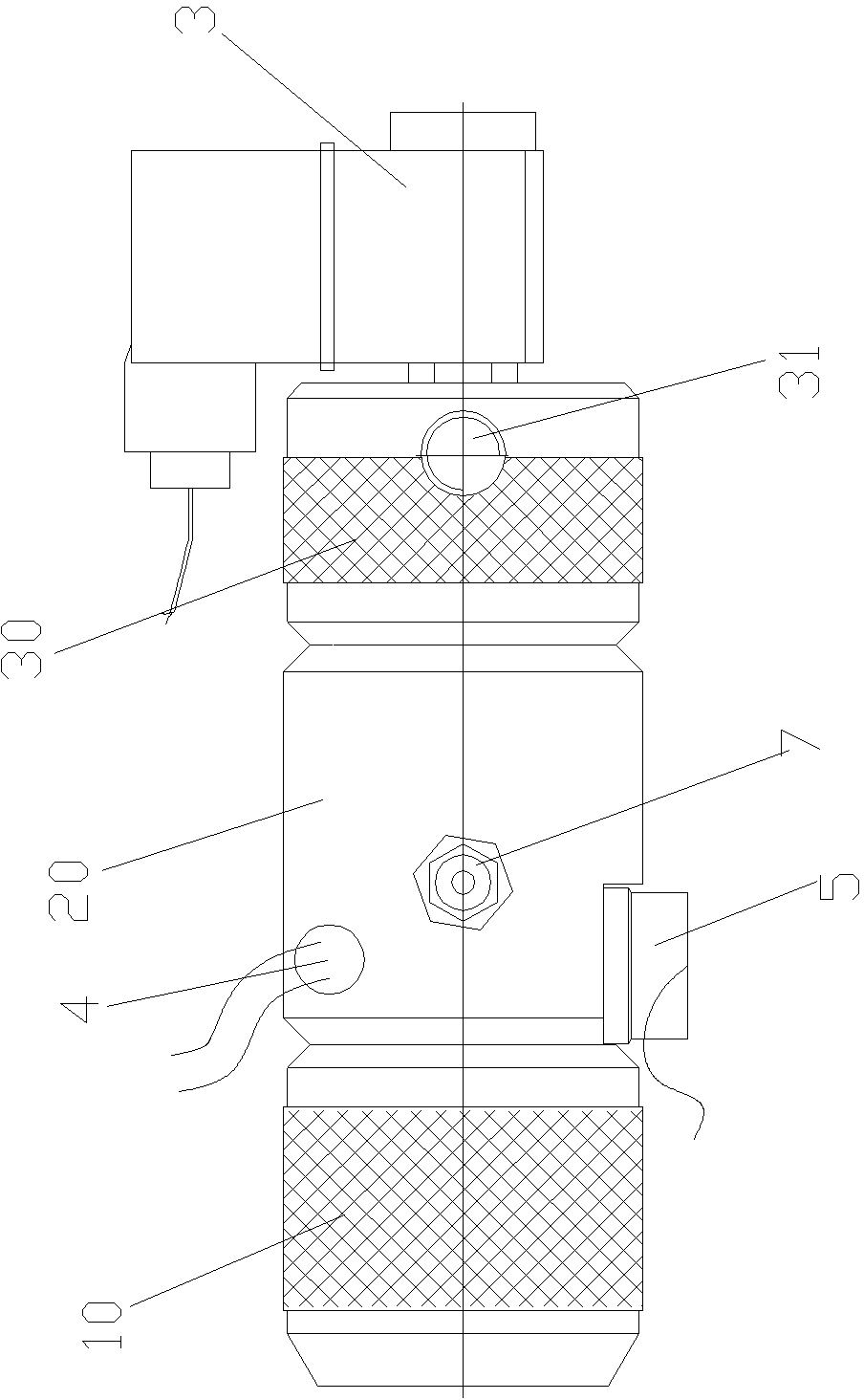

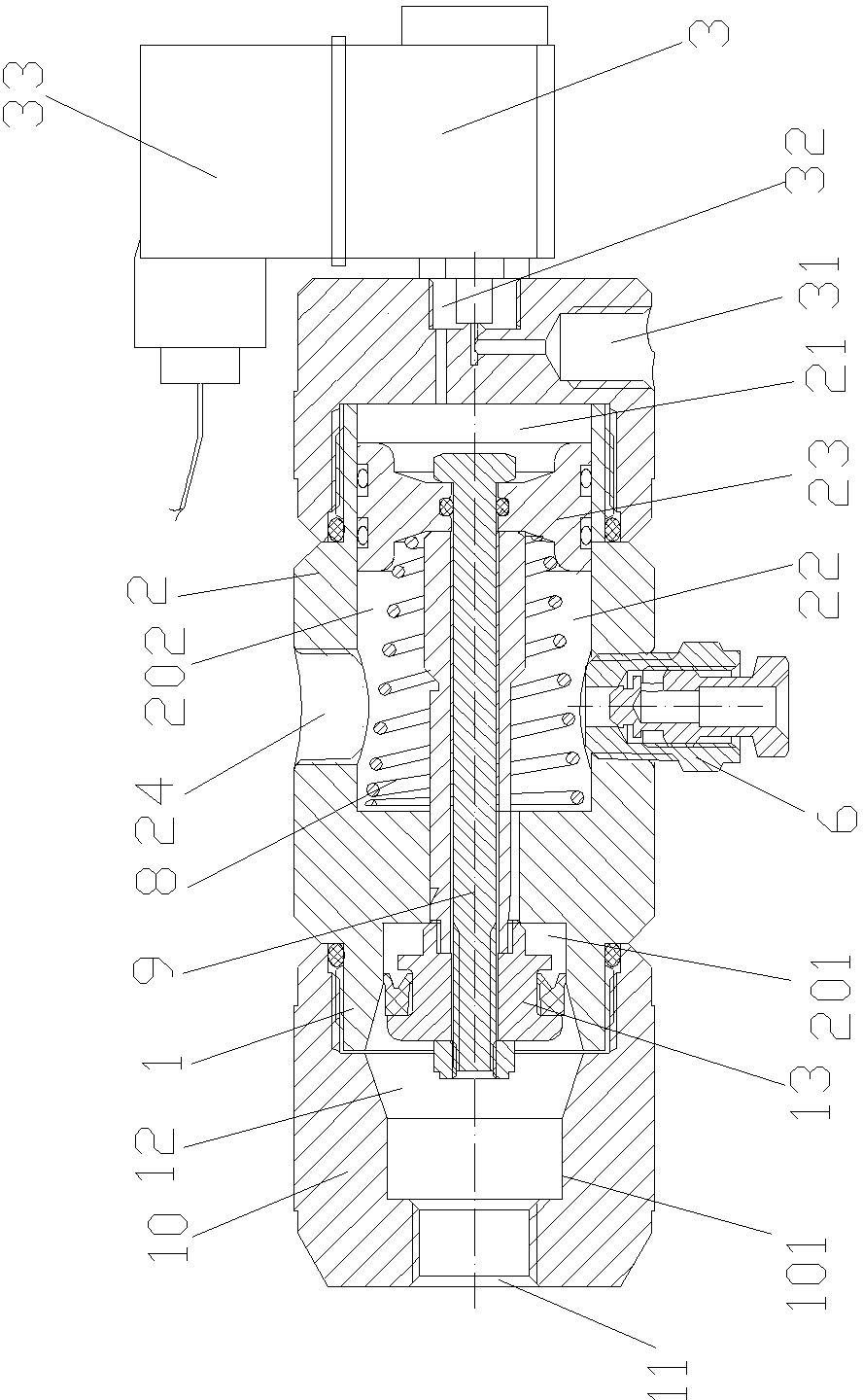

[0017] Such as figure 1 , figure 2 As shown, an embodiment of a sewage shut-off valve, the sewage shut-off valve in this embodiment includes a pilot valve, a piston device 2 and a main valve 1 arranged in sequence from front to back along the front-to-back direction, and the main valve 1 is provided with a valve cavity 12. The valve chamber 12 has an inlet and an outlet, and a spool 13 for controlling the on-off of the inlet and outlet of the valve chamber is installed in the valve chamber 12 to control the opening or closing of the main valve. The sewage cut-off valve has a liquid inlet 24 communicated with the inlet of the valve chamber 12 and a liquid outlet 11 communicated with the outlet of the valve chamber. There is a piston cavity in the piston device 2 here, and a piston 23 is installed to reciprocate along a linear direction in the piston cavity. The piston 23 separates the piston cavity into a first cavity 21 and a second cavity 22. In the front, the second chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com