Fault current limiter on basis of combined rapid switch-on switch

A closing switch, fault current technology, applied in emergency protection circuit devices, electrical components, circuit devices for limiting overcurrent/overvoltage, etc., can solve the problem of high cost, achieve fast response, market competitiveness, The effect of reducing the short-circuit capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

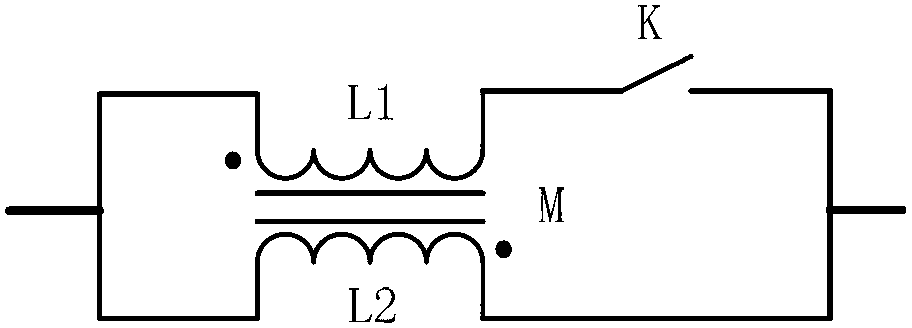

[0035] The fault current limiter based on the combined fast closing switch of the present invention is composed of a conventional reactor or a close-coupled double-winding reactor with the same name and end, a capacitor and a combined fast closing switch. The combined fast closing switch is composed of a double-winding reactor with opposite ends of the same name and a fast closing switch K.

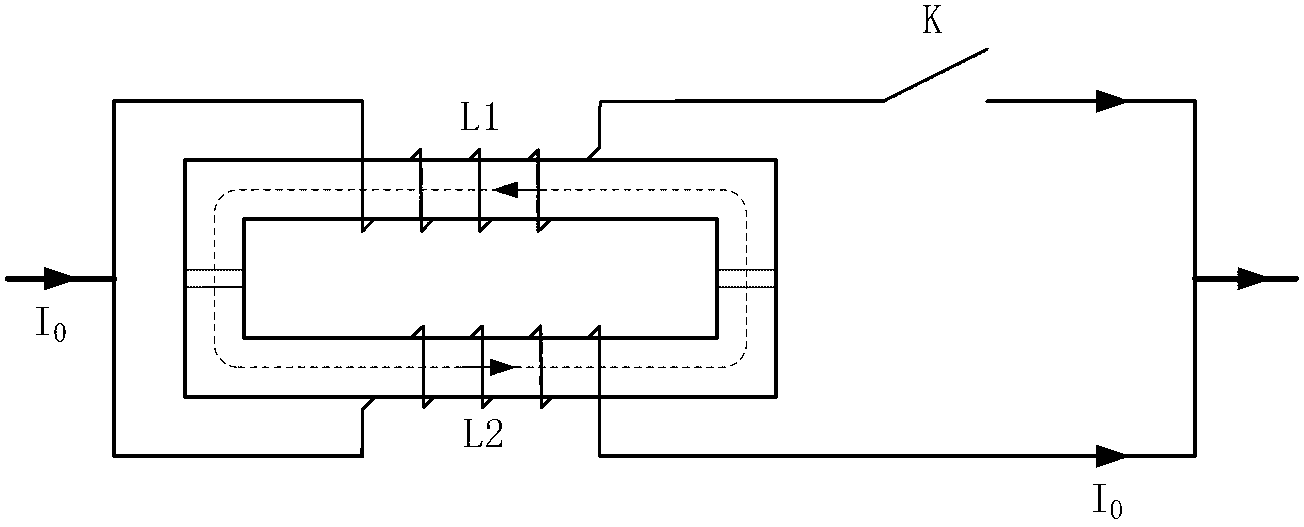

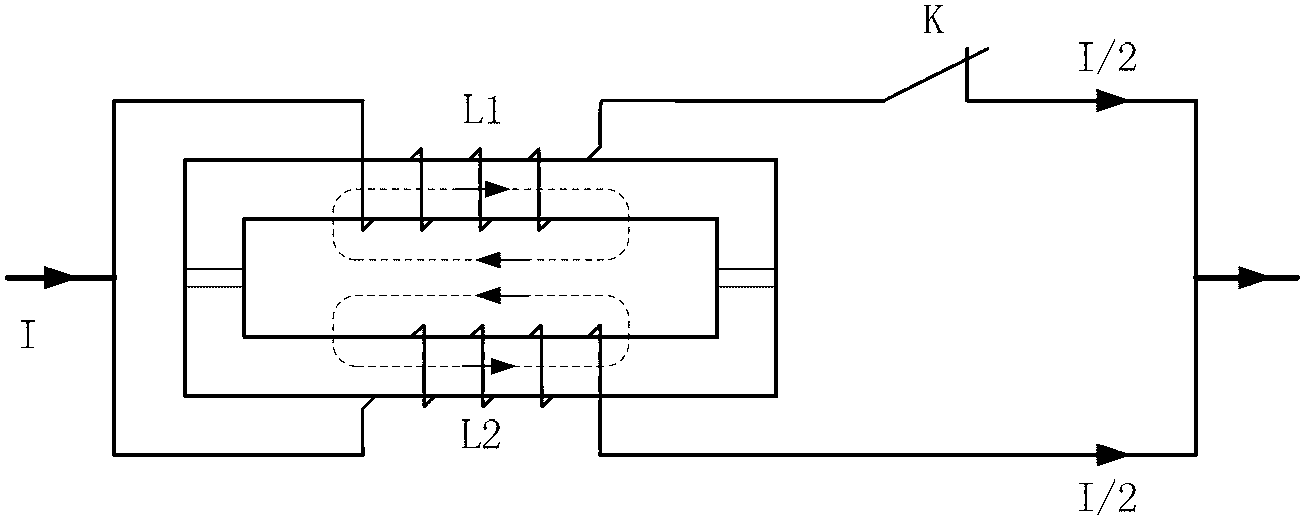

[0036] figure 1 Shown is the circuit and magnetic circuit diagram of the combined fast closing switch in steady state operation. Such as figure 1 As shown, the combined fast closing switch is composed of a double-winding reactor with the opposite end of the same name and a fast closing switch K. The double-winding reactor with the opposite end of the same name is composed of the first winding L1, the second The winding L2 is composed of a rectangular ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com