Spring press fitting device of adjusting block

A technology for spring pressing and adjusting blocks, which is used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high requirements for workers' arm strength, increase workers' wage costs, and difficulty in manual assembly of workers, so as to reduce labor costs and reduce labor costs. The effect of less labor and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

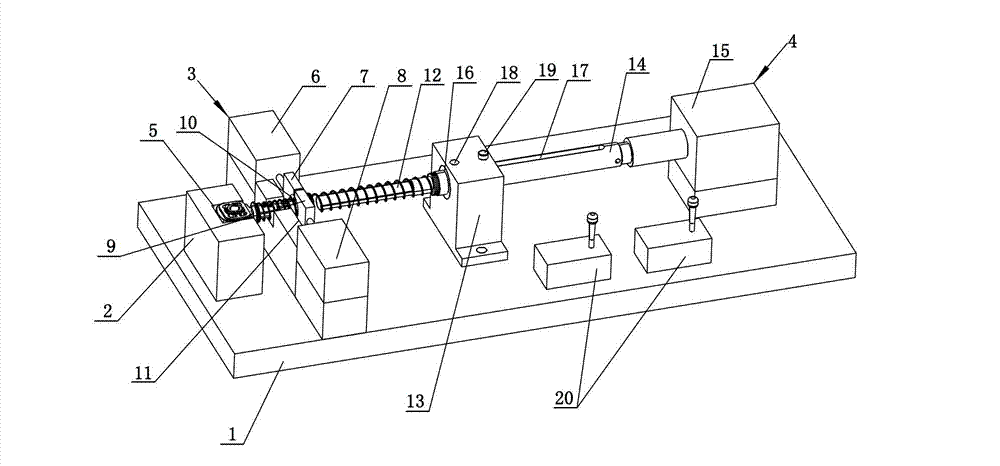

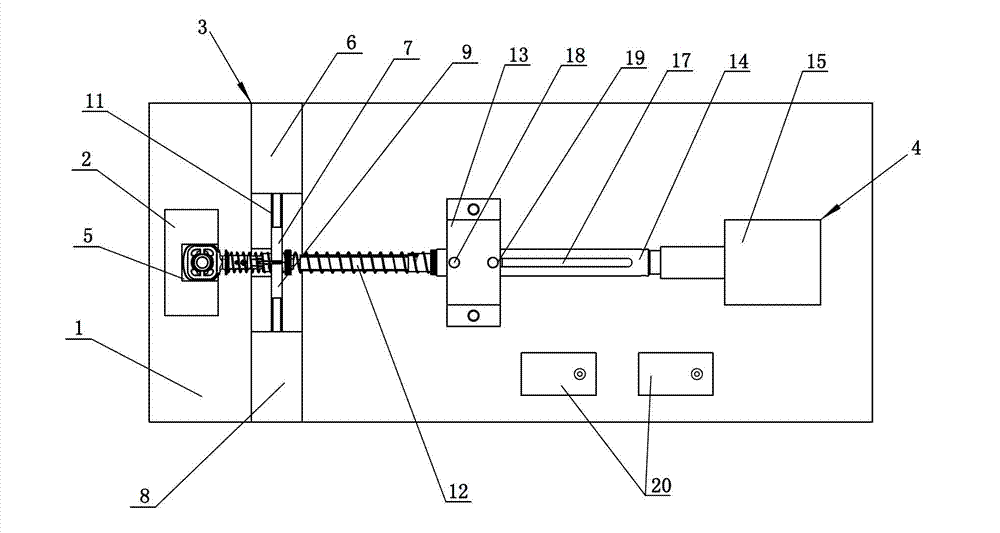

[0015] Such as figure 1 with figure 2 A spring pressing device for an adjustment block is shown, which includes a bottom plate 1, an adjustment block limit block 2, a claw pressing mechanism 3 and a sleeve mechanism 4, and the adjustment block limit block 2, claw pressing Both the mechanism 3 and the set mechanism 4 are fixed on the bottom plate 1. The claw pressing mechanism 3 is located between the regulating block, the limit block 2 and the set mechanism 4. Generally, there are separate controls for the claw pressing mechanism 3 and the set mechanism. The switch 20 of mechanism 4.

[0016] The adjusting block limiting block 2 is provided with a groove 5 for limiting one end of the adjusting block. Of course, the shape of the groove 5 is the same as that of the end of the adjusting block away from the claw.

[0017] The claw pressing mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com