Cutting equipment for manufacturing iron picture and iron picture cutting method using equipment

A kind of equipment, iron painting technology, applied in shearing machine equipment, metal processing equipment, shearing device and other directions, can solve the problems that scissors are difficult to stabilize, laborious and time-consuming, and require high operator skills, so as to achieve stable and convenient use, reduce costs, and save production. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] With reference to the accompanying drawings, the specific implementation of the present invention will be further described in detail through the description of the embodiments to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concept and technical solution of the present invention.

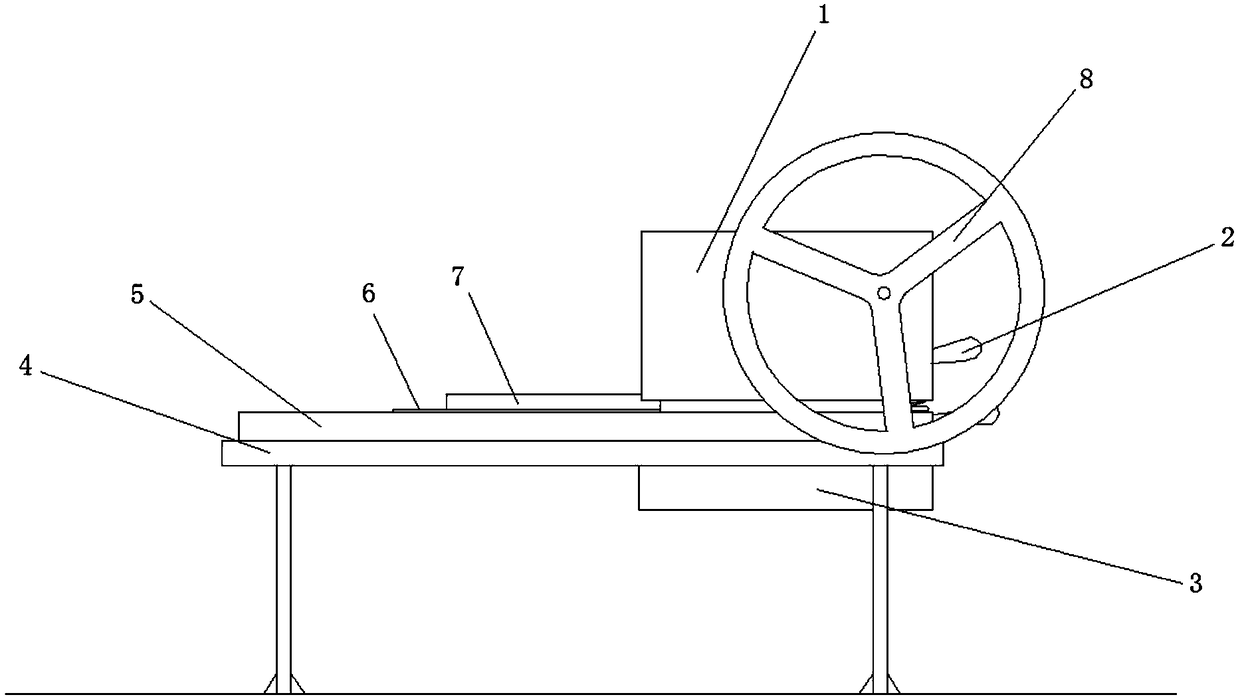

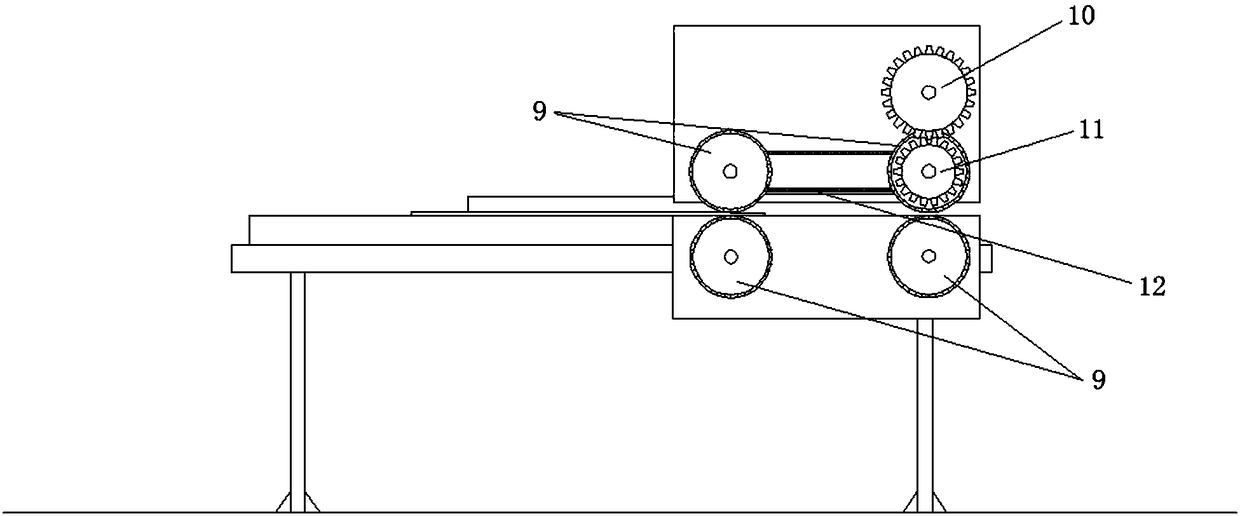

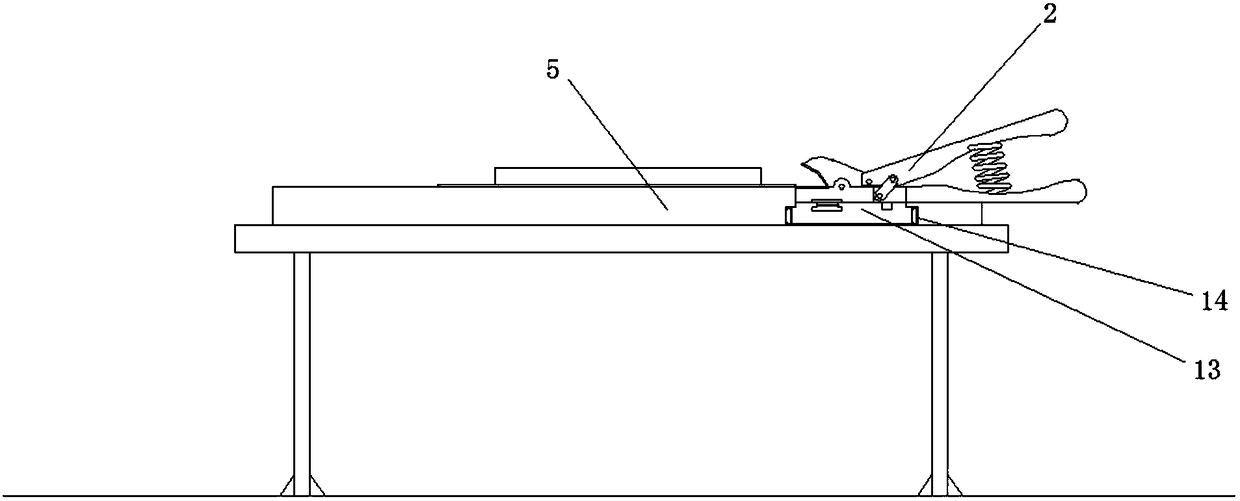

[0033] Such as Figure 1 to Figure 6 As shown, the present invention provides a cutting device for making iron paintings, which includes a workbench 4, an equipment substrate 5 installed on the workbench 4, an iron plate conveying mechanism, and a cutting mechanism. The cutting mechanism includes a scissors sliding seat 13 and an iron plate scissors 2 mounted on the scissors sliding seat 13. Before use, the workbench 4 is adjusted to ensure the level of the top plane of the equipment substrate 5.

[0034] This equipment takes the direction the operator faces when operating as the front, and the operator sits behind the equipment to work...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com