Double-point positioning compounding clamping device

A clamping device and point positioning technology, which is applied to workpiece clamping devices, manufacturing tools, etc., can solve the problems of unreasonable structural design of clamping devices, time-consuming and labor-intensive operation, and high production costs, shortening processing time, The effect of reducing labor intensity and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

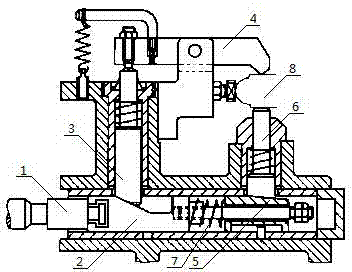

[0010] like figure 1 As shown, the present invention provides a double-point positioning composite clamping device, including a transmission member 1, a thrust block 2 connected to the transmission member 1, a push rod 3, a pressure plate 4 hinged on the frame, an inclined block 5 and a push column 6 , one end of the push rod 3 is connected to the thrust block 2, and the other end is detachably connected to the pressure plate 4; one end of the slant block 5 is connected to the thrust block 2 through a shaft, and the slant block 5 is connected to the push column 6 by transmission; the push rod 3, the slant Block 5 and push post 6 are all provided with fine-tuning spring 7.

[0011] In this embodiment, the setting of the thrust block 2 is very critical. On the one hand, the thrust block 2 has an upward force on the push rod 3, so that the push rod 3 moves upward, so that the connecting end of the pressure plate 4 is lifted, and the freedom of the pressure plate 4 The end moves ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap