Method and device for manufacturing sticking film with three-dimensional pattern

A manufacturing method and a manufacturing device technology, which are applied in the field of film manufacturing that present three-dimensional patterns, can solve the problems of lack of realistic dynamics and no three-dimensional effect of film patterns, and achieve the effects of improving market competitiveness, clear patterns, and rich expressiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

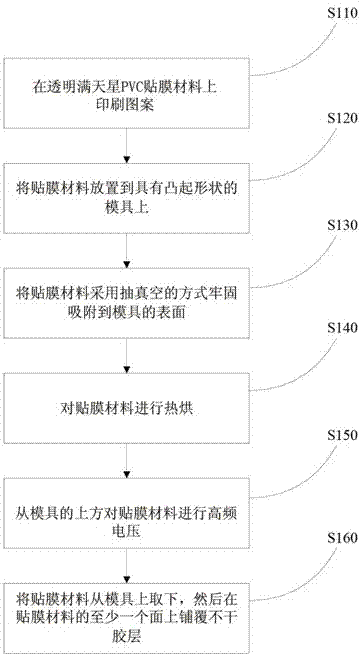

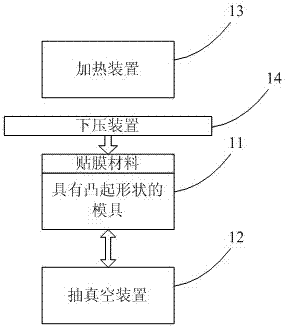

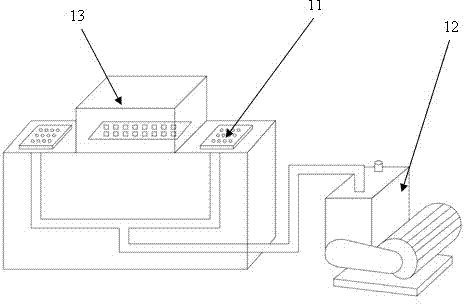

[0027] Such as figure 1 As shown, the present invention presents the workflow of the film manufacturing method of three-dimensional pattern and comprises the following steps:

[0028] S110, printing patterns on the film material;

[0029] S120, placing the film material on a mold having a raised shape;

[0030] S130, firmly adsorbing the film material to the surface of the mold by vacuuming;

[0031] S140, heating the film material;

[0032] S150, pressing down the film material from above the mould;

[0033] S160. The film sticking material is removed from the mold, and then a self-adhesive layer is spread on at least one surface of the film sticking material.

[0034] According to one embodiment of the present invention, after the step of pressing down the film material from above the mould, a step is also included: removing the film material from the mold, and then covering at least one surface of the film material with a self-adhesive layer . The film material is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com